Structural steel is increasingly used in prefabricated steel frame buildings and constructed traditionally with outstanding advantages such as diverse shapes, types, and sizes to meet many requirements of use, easy to fabricate, and abundant product sources in the market. Join Pebsteel to learn and classify steel shapes, types, and practical applications of this construction material type.

Read more: Steel Structure Introduction

1. What is structural steel?

Structural steel is a type of steel used as a construction material in various shapes. These shapes are often designed with specific cross-sectional profiles resembling elongated beams.

Structural steel is designed with the shape and size according to the specifications suitable for different projects in buildings, roads, bridges, etc. Some methods of fabricating this type of material are hot rolling, cold rolling, complex welding, bending, etc.

Read more: Pre-engineered Steel Buildings: Components And Applications

2. Structural Steel Types and Grades

There are multiple varieties of structural steel, each designed for specific applications. Structural steel comes in various shapes and grades, chosen based on the project’s requirements. The classification of structural steels is determined by the shape of their cross-sections, with commonly used figures including I, T, and C shapes. Additionally, the mechanical properties of the steel are directly influenced by its grade. Consequently, selecting different degrees of structural steel is essential to meet diverse design criteria.

Read more: What Is Structural Steel Welding? Definition And Methods

Here are the popular and standard structural steel materials types:

2.1. Carbon steels

Carbon steel is a type of steel that contains carbon as the primary alloying element (such as zirconium, cobalt, nickel, etc.), with other elements present in smaller amounts (does not exceed Cu 0.4% and does not exceed indicated percentages in weight (Mn: 1.6%, Si: 0.6%, Cu: 0.6%).

It is the most common type of steel, accounting for over 90% of all steel produced. Carbon steel comprises iron and carbon, with carbon content ranging from 0.05% to 2.1% by weight. Based on carbon content, the category of carbon steel regular as:

- Low-carbon steel (< 0.3%)

- Medium-carbon steel (0.3-0.6%)

- High carbon steel (0.6-1%)

- Ultrahigh carbon steel (1.25-2%)

Carbon steel is mostly used in structural pipes and tubing. Carbon steel is a versatile and affordable material that is used in a wide variety of applications. However, it is important to note that carbon steel is susceptible to corrosion, so protecting it from the elements is important.

Read more: Application of Cold Rolled Steel

2.2. High-Strength Low-Alloy Steels

High-strength low-alloy (HSLA) steel is a type of alloy steel that provides better mechanical properties or greater resistance to corrosion than carbon steel. High-strength low-alloy steels vary from other steels in that they are not made to meet a specific chemical composition but rather specific mechanical properties.

HSLA steels are typically made with low levels of alloying elements, such as manganese (up to 2%), vanadium, titanium, molybdenum, or boron. These elements can be added singly or in combinations to achieve the desired properties.

Overall, High-strength low-alloy steels are more corrosion-resistant than carbon steel, particularly atmospheric corrosion. It is mostly used in structural shapes and plates.

Read more: What is Synthetic Steel? Features and Classifications

2.3. Forged Steels

Forged steel is a type of steel that has been shaped by hammering or pressing it into a desired shape. This process is called forging. Forged steel is typically stronger and more durable than other types of steel, such as cast steel or rolled steel.

Forging is accomplished by heating the steel to a high temperature and applying pressure. It applies mechanical and thermal energy to steel ingots or billets. The pressure causes the steel to deform and flow into the desired shape. Forged steel is often used to produce gears, bearings, shafts, hinges, valves, and other components.

Read more: Advantages Of Pre-fabricated Corrugated Steel Floor And Common Industrial Floor Types

2.4. Quenched And Tempered Alloy Steels

Quenched and tempered alloy steels are a type of steel subjected to a heat treatment process. This process gives the steel increased strength, hardness, and toughness.

- Quenching involves heating the steel to a high temperature and then rapidly cooling it in a liquid, such as water or oil. This causes the steel to form a hard martensitic microstructure.

- Tempering involves reheating the quenched steel to a lower temperature and slowly cooling it. This softens the martensitic microstructure and makes the steel more ductile.

Quenched and tempered alloy steels are commonly used in construction buildings, as well as for shafts and bolts, and in the mining industry.

Read more: Bolt Connections In Steel Structure

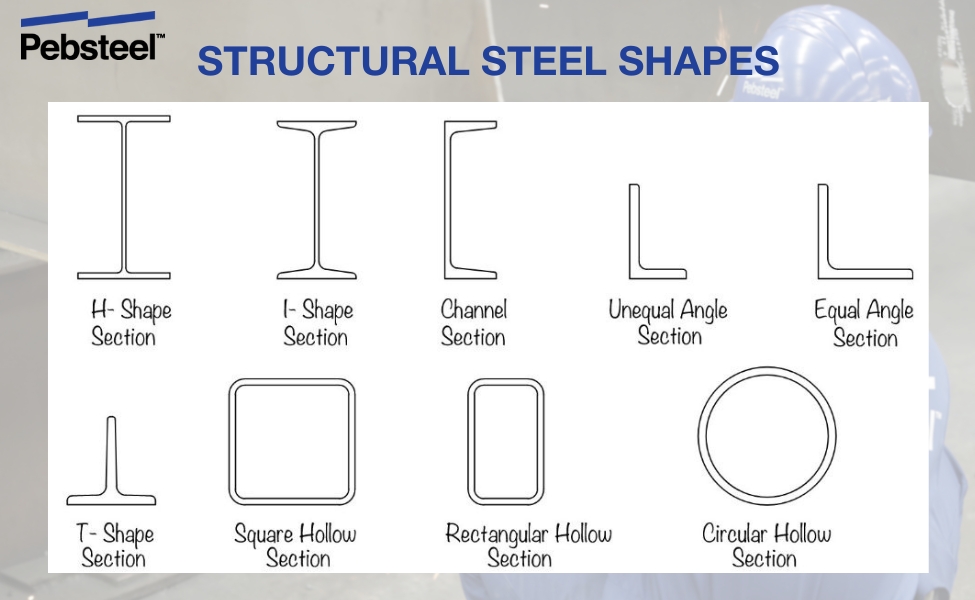

3. Standard common structural steel shapes

Structural steel shapes are defined by many standards worldwide, including angles, tolerances, dimensions, and cross-sectional measurements. These standards also name the different steel shapes. Many sections are formed by hot or cold rolling, while others are made by welding together flat or bent plates.

Here are standard common structural steel shapes:

- L- shape: is often used as a corner section in construction, industry, commerce, transportation, or mining.

- U-shape: two sides parallel to the correct angles resemble the shape of the letter “U”. This type has relatively high durability.

- C-shape: has a cross-section resembling the letter “C”; this form is used to make purlins below the roof with a supporting effect.

- Z-shape: there is a cross-section resembling the letter “Z”, similar to the form of “C”, this form is also mainly used to make purlins.

- Tubular hollow cross form: tubular hollow cross sections are highly resistant to twisting and are used mainly in multi-axis constructions.

- Flatform: often referred to as plates, used to attach to construction parts to enhance bearing strength.

- Rectangular hollow cross-section: The rectangular open cross-section resembles the circular hollow cross-section. This type is often used in many mechanical and construction steel industries.

- Square hollow cross-section: Since this form is difficult to combine with other forms, the square open cross-section is used only as a column or pillar of the building.

- Taper-shaped beams and columns: popular in industrial prefabricated steel buildings.

Read more: Application of Cold Rolled Steel

4. Advantages and Disadvantages of Structural Steel

| Advantages | Disadvantages |

|---|---|

| Higher strength/weight ratio | Susceptible to corrosion |

| High durability | High fire resistance cost |

| Versatility due to good ductility | |

| Sustainability |

4.1. Higher strength/weight ratio

Structural steel has a very high strength-to-weight ratio, which is very strong for its weight. This is one of its main advantages over other construction materials, such as wood and concrete.

4.2. High durability

Structural steel is a highly durable material that can withstand decades of use in even the harshest environments. The high durability of structural steel makes it ideal for use in applications where long-term performance and reliability are critical. For example, structural steel is used to construct bridges, buildings, and other structures expected to last for many decades.

4.3. Versatility due to good ductility

Structural steel is a highly versatile material due to its good ductility. Structural steel is very ductile, which means that it can be bent and shaped into a variety of different forms. This makes it ideal for use in a wide range of constructions.

4.4. Sustainability

Structural steel is a sustainable material that can be recycled repeatedly. In fact, steel is one of the most recycled materials in the world. In 2021, the steel industry recycled 1.6 billion tons of scrap, equivalent to 74% of the steel produced that year.

Recycling steel has many environmental and economic benefits. It reduces the need to mine and process new iron ore, which saves energy and reduces greenhouse gas emissions. It also helps to conserve landfill space.

By carefully considering the disadvantages of structural steel and taking steps to mitigate them, engineers and architects can complete design and construct safe, durable, and aesthetically pleasing structural steel structures.

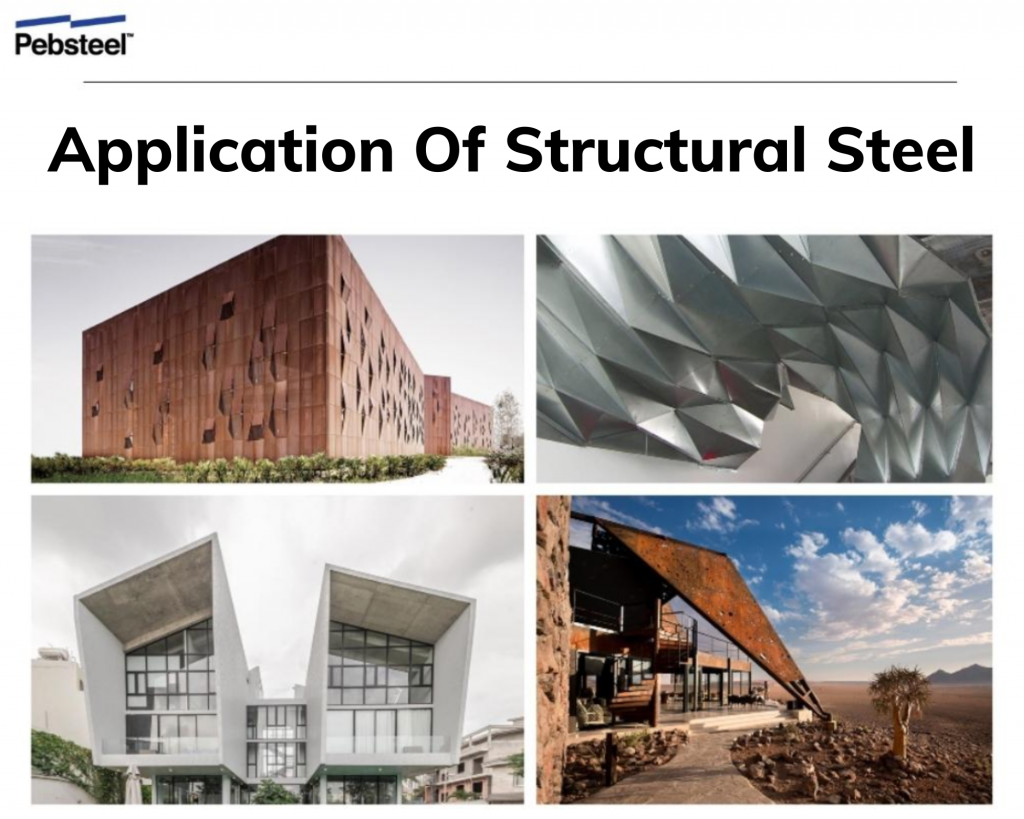

5. What is structural steel used for?

Structural steel is typically used in a variety of applications, including:

- Buildings: Structural steel is the backbone of many modern buildings, from skyscrapers to homes. It is used to create the frames that support the weight of the walls, floors, and roof.

- Bridges: Structural steel is also used to build bridges, which can be very long and span large distances. It is strong enough to support the weight of vehicles and pedestrians, and it can also withstand the forces of wind and water.

- Towers: Structural steel is used to build towers, such as telecommunications towers and wind turbines. These towers must be able to withstand strong winds and other extreme weather conditions.

- Other structures: Structural steel is also used in a variety of other structures, such as warehouses, stadiums, and industrial plants.

Structural steel is a versatile and durable material that is essential for modern construction. It is strong, lightweight, and relatively inexpensive, making it an ideal choice for a wide variety of applications.

Read more: Construction Of Pre-engineered Steel Factory 2023

5.1. Be a framework for commercial construction

5.2. Be a factory framework for workshops, manufacturing factories

Read more: Price Quotes for Construction of High-rise Pre-engineered Steel

5.3. Be a framework for civil steel frame buildings

5.4. Used to make road bridges

5.5. Used to make C and Z purlins when constructing corrugated steel roof

In addition, structural steel is also used to make transceiver columns, antenna columns, railways, storage tanks,…

6. FAQs about Structural Steel

6.1. What are structural steel types?

The most common types of structural steel include Carbon steel, High-Strength Low-Alloy Steel, Forged Steel, and Quenched And Tempered Alloy steel. Structural steel is a type of steel that is specifically designed for use in the construction of load-bearing structures.

6.2. How much is the structural steel price?

Vietnam's average reference structural steel price is around $900 per ton. However, prices can vary significantly depending on factors, including the type of steel, the grade of steel, the thickness of the steel, and the quantity of steel being purchased.

The above article has provided customers with the necessary information about structural steel. If you have any questions about the article, please get in touch with us at the following email: marketing@pebsteel.com.vn or phone number +84 908 883531 for the fastest assistance.

Pebsteel is a global enterprise specializing in providing solutions for prefabricated steel buildings and steel structures. During its operation, the company has carried out more than 6000 different projects in many countries such as Vietnam, Thailand, Laos,… Therefore, Pebsteel is always committed to providing customers with comprehensive, professional service throughout the project and maintaining customer support. Some standard services in Pebsteel that customers can refer to are the construction of prefabricated buildings with high-standard contract systems, providing corrugated steel roof systems, and high-end construction accessories.

If you want to receive a quote, don’t hesitate to get in touch with +84 908 883531 for free advice.