After a long period of operation, a factory or warehouse will encounter some issues, the most common being leakage. Leakage causes water to seep inside, affecting goods and slowing down the work progress of the workers. In the following article, let’s explore effective and cost-saving ways to prevent factory roof leaks with Pebsteel.

Read more: Five Main Applications Of Metal Buildings

1. The cause of water penetration and leaks in factories

Vietnam frequently experiences heavy rain and storms, easily damaging building metal roofs. Therefore, reinforcing the metal roof with anti-leakage measures will enhance its durability and resistance to weather impacts. The main causes of the condition of leakage on metal roofs are listed below:

- The roofing installation process needs to meet the required quality standards.

- Choosing low-quality roofing leads to rapid deterioration.

- Rainwater corrodes the roofing when used for an extended period.

- Water seeps in through the screw holes in the metal sheets.

- Leakage occurs due to wave overflow at the intersecting joints of the roofing sheets.

- Leakage appears at the joint between the two roofs of two adjacent houses.

2. Some practical ways to prevent roof leaks in factories

2.1. Treating punctured roofs

Metal roof sheets often get punctured in the middle from inattentive screwing during construction, transportation, or installation. The sheets can also become dented from impacts, leading to rust and holes. For minor punctures, silicone sealant or anti-leakage tape can be used to seal and cover the damaged areas

For larger punctures ranging from 5cm to 10cm, first, the surface of the metal at the puncture location needs to be cleaned to ensure it’s free from dirt, allowing the adhesive to stick better. Then, use a large piece of anti-leakage tape to cover the area. This tape typically has a lifespan of only 1 to 2 years and is a temporary measure to prevent leakage. However, for a long-term solution, using a small metal patch to reinforce or using self-tapping screws to secure the metal, followed by applying adhesive around the anti-leakage tape, is the best approach.

2.2. Preventing factory leaks at joints

The areas where metal sheets overlap and meet are wave overlap joints. After exposure to rain and wind, these overlap joints may become dislodged, or the screws may become loose. In addition, water can seep into these wave overlap joints during periods of heavy rain and strong winds, leading to leaks. However, this situation can be easily addressed by re-screwing these areas and adding adhesive to enhance their stability.

2.3. Preventing factory leaks at the location adjacent to the wall gap

In this instance, filling the gaps at the junctions with a cement mortar slurry will prevent rainwater from entering the building. Using anti-leakage tape for metal roofs to seal the junctions between two houses is also a solution to deal with this situation. Additionally, customers can use large-sized metal sheets (1000 cm or 2000 cm) and cut them into smaller-sized sheets (500 cm) for utilization. The metal roof has been solidly reinforced with rivets or screws, preventing it from being blown away by the wind.

See more: Quotation Of Warehouse Construction Costs

3. How to prevent roof leaks in prefabricated factories for export industries?

The above solutions for preventing leakage are highly suitable for pre-engineered export-oriented factories. However, due to the specific nature of projects related to exports, it is necessary to adhere to stringent standards. Investors should consider additional effective anti-leakage measures.

Optimizing the automation process and standardizing the production process in pre-engineered factories is crucial to prevent leakage. Additionally, using high-quality materials and implementing advanced technology during construction helps prevent roof leaks in the factory. Furthermore, during the installation of metal roofs, workers should ensure the process is carried out meticulously and incorporate surface coating to prevent leakage. Regular inspection and maintenance play a crucial role in maintaining and improving the quality of the metal roof.

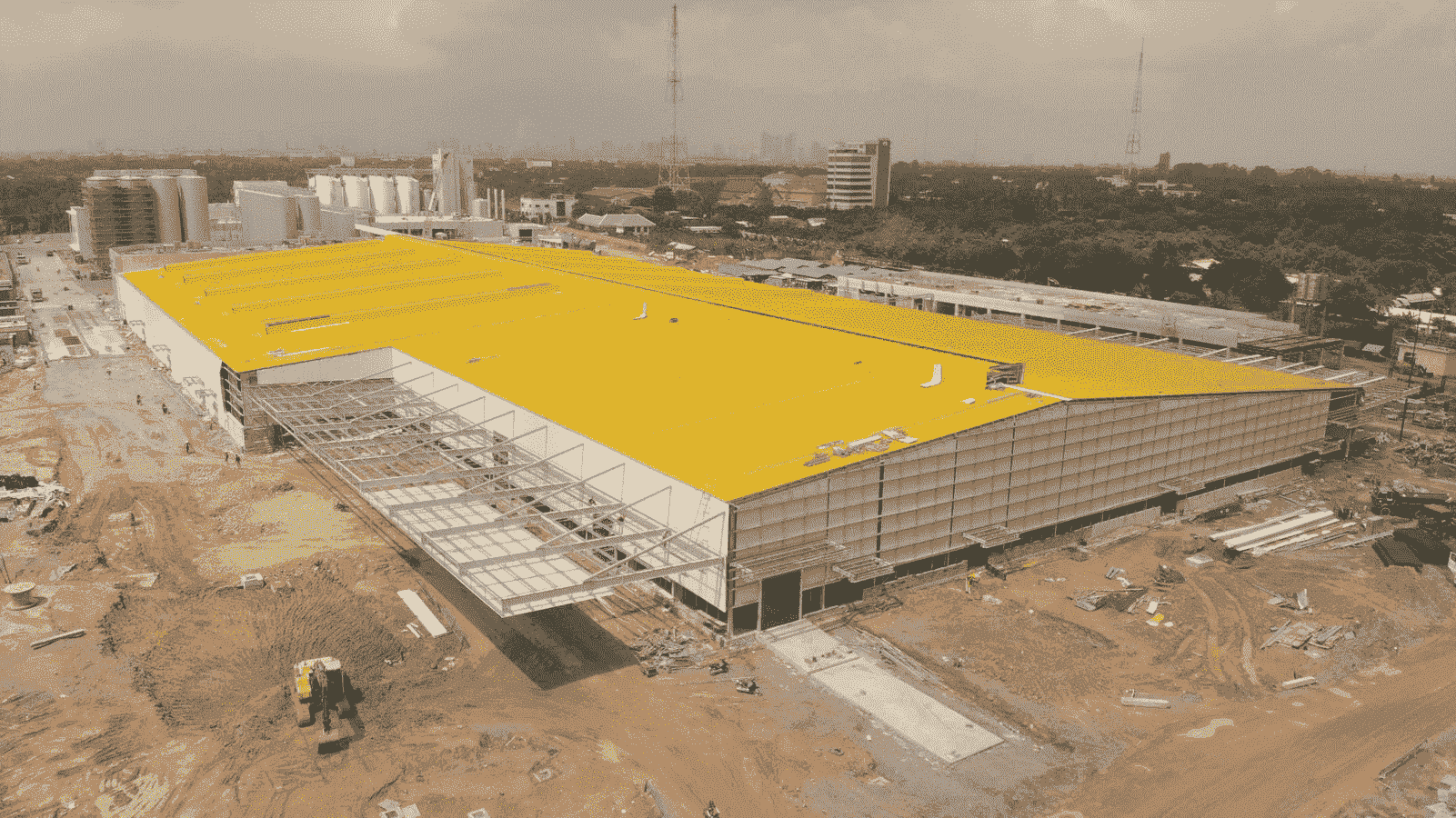

To ensure the quality of the factory’s metal roof and minimize the occurrence of leaks, you should consider choosing a reputable construction company and using high-quality metal sheets from the construction phase. LokSeam metal roofing is the optimal choice for pre-engineered factory projects. This product boasts exceptional leak resistance and helps the project avoid damage caused by thermal expansion. With extensive experience in designing industrial factories for various sectors, Pebsteel is fully capable of meeting the most stringent standards while constructing pre-engineered factories.

4. Conclusion

Above are details about methods to prevent leakage and the common causes leading to this condition. If customers seek comprehensive solutions for Pre-Engineered Buildings and Steel Structures, please contact Pebsteel via email at Marketing@pebsteel.com.vn or call +84 908 883531 for an immediate consultation.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.