1. What is prefabricated warehouse construction? What are its advantages?

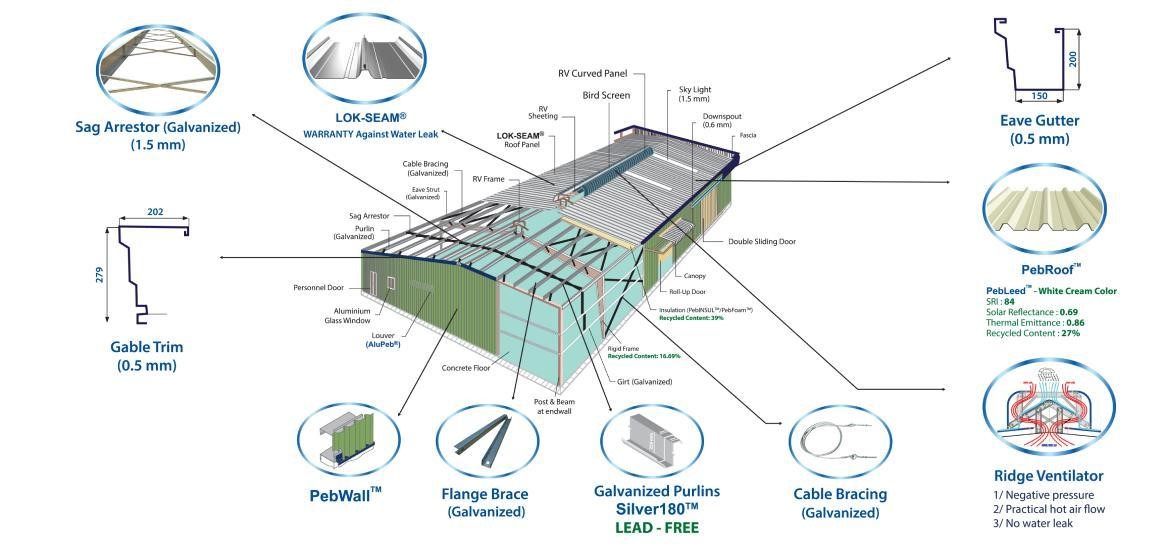

A prefabricated warehouse construction consists of main components: prefabricated steel frame system, galvanized purlins (walls and roof), roof panel, wall panels, and other accessories (trim, galvanized bracing cables, gutters, ridge ventilators, etc.). These steel components are manufactured and assembled based on the technical design with accurate dimensions and quantities.

A prefabricated warehouse construction offers prominent advantages to investors:

- Cost savings on materials and foundation treatment.

- Faster construction time compared to concrete buildings.

- Easy maintenance, upgrade, and expansion.

- High durability, optimizing operational and maintenance costs.

Structure of Pebsteel’s prefabricated steel building

Read more: Warehouse Construction Process and Keys Factors to Note

2. Choosing a suitable frame for prefabricated warehouse

Based on the specific function and usage of the facility, Pebsteel will recommend appropriate framing solutions for the prefabricated warehouse using structural steel. Pebsteel offers a variety of standard steel framing systems such as:

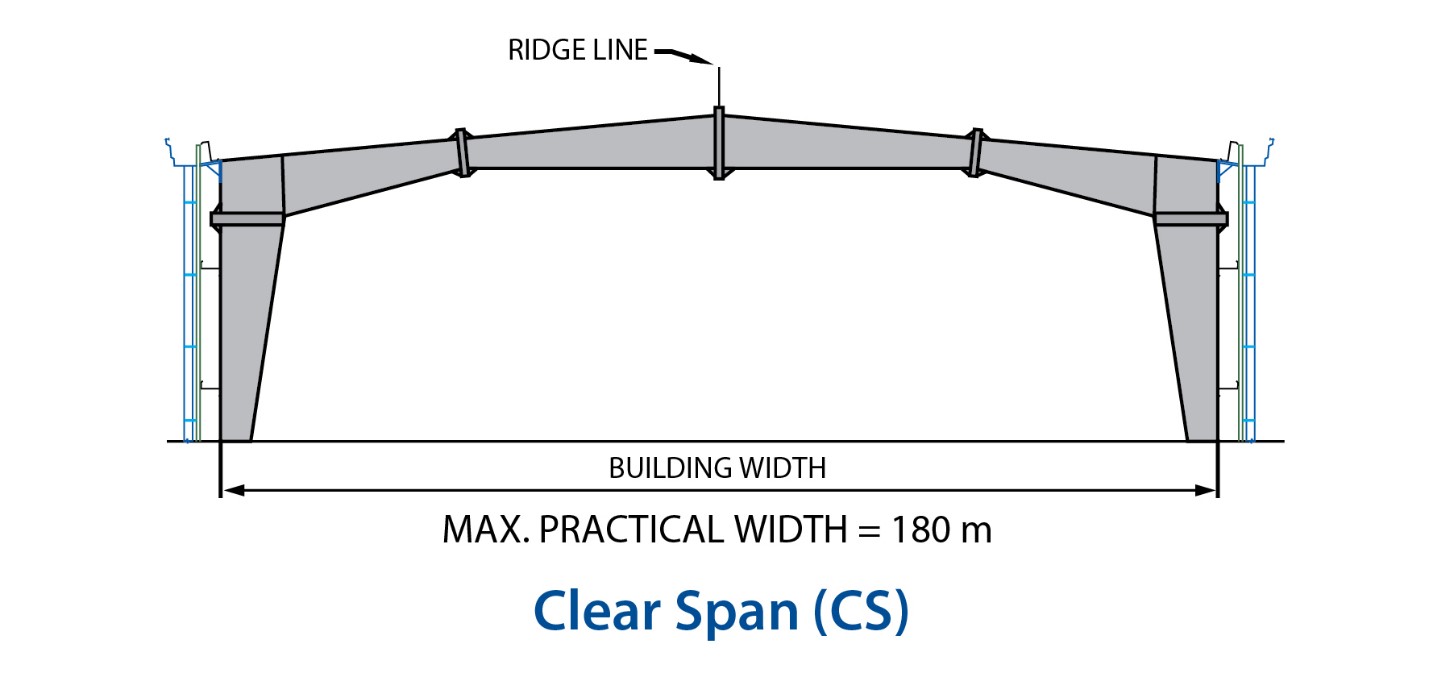

- The clear span frame system: With a width of up to 180 meters, ideal for logistics warehouses, manufacturing plants, aircraft hangars, auditoriums, and large-scale entertainment venues

Clear span frames in warehouse construction

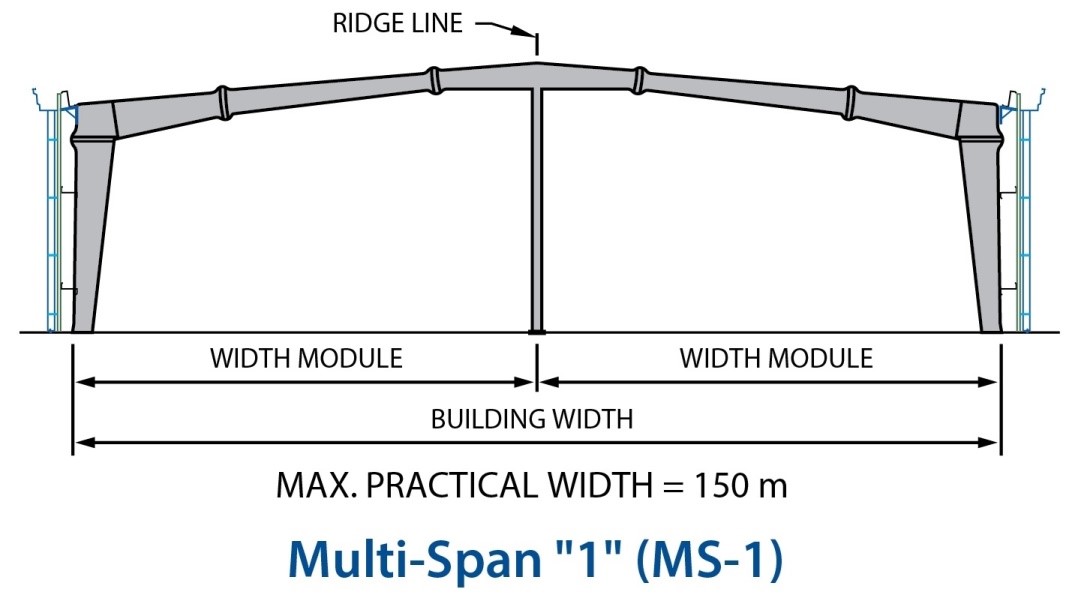

- The multi-span frame system (with interior columns): Suitable for ultra-wide structures with low-slope roofs and can meet the usage requirements of warehouses, logistics centers, manufacturing plants, etc.

Multi span in warehouse construction

- The lean-to truss is a cost-effective solution for investors looking to expand or add onto existing buildings, particularly for warehouse facilities or office buildings.

Lean to truss in warehouse construction

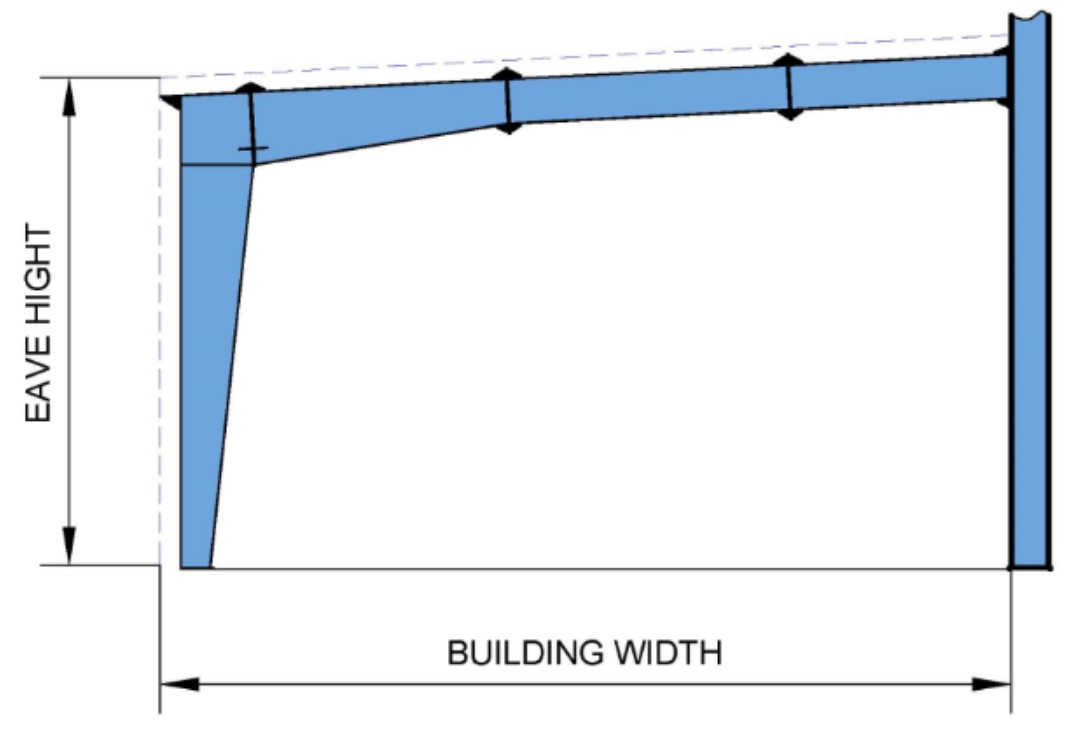

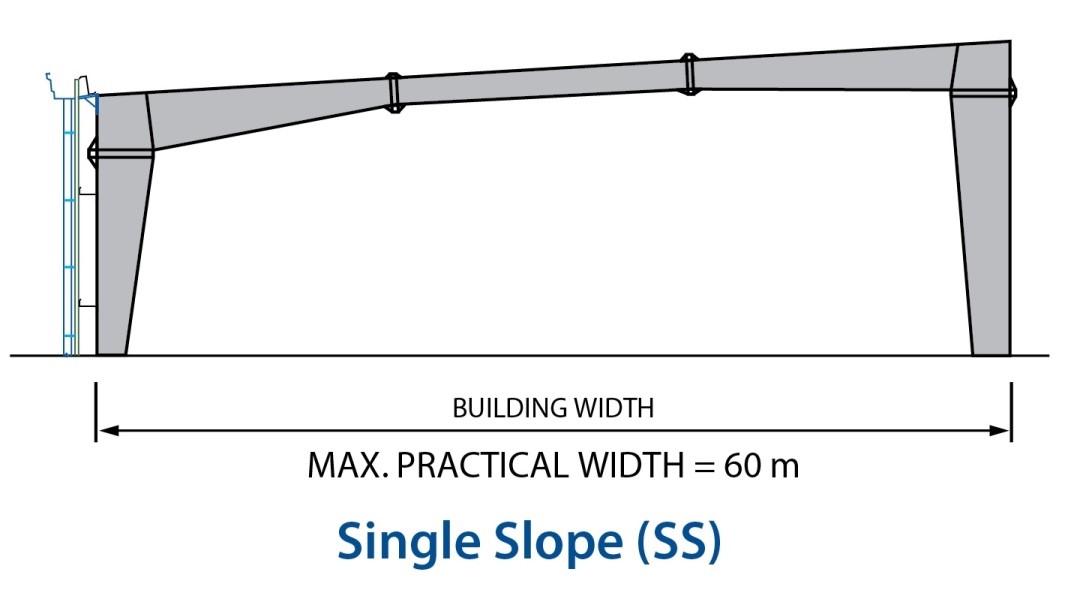

- Single Slope frame is a cost-saving solution for buildings under 12 meters in width, commonly applied in shopping centers, office buildings, warehouses, shipyards, etc.

Single Slope frame in warehouse construction

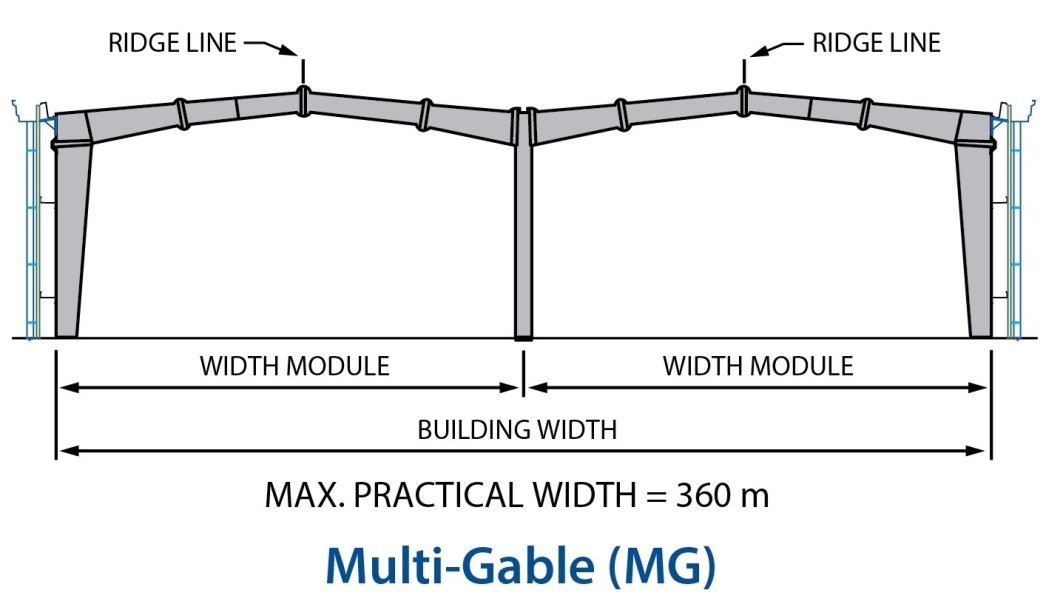

- Multi-Gable frame is suitable for large-scale projects, helping save materials by reducing the height of the roof system.

See more: Warehouse Construction Costs Update

Multi gable frame in warehouse construction

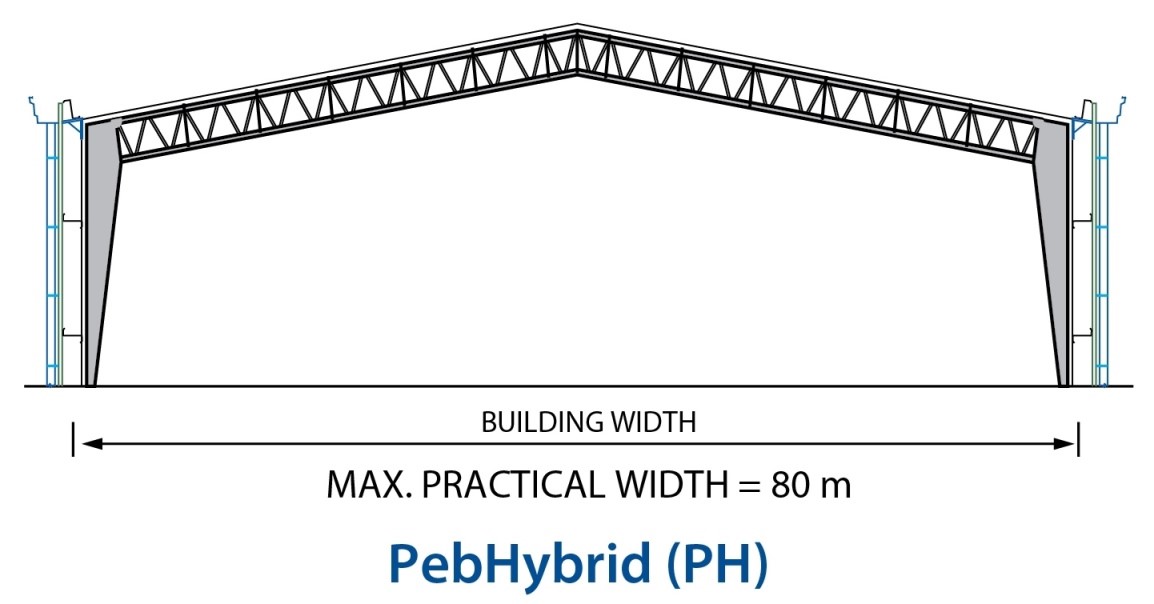

- PebHybrid® is a hybrid truss frame developed by PebSteel Buildings to optimize materials use and reduce structural weight by up to 20% compared to other truss frames. Specifically reinforced steel columns are used in warehouse buildings equipped with overhead cranes. PebHybrid® trusses can be applied to standard frame designs such as clear span, single slope, multi-gable, center column, and roof systems.

Pebhybrid frame in warehouse construction

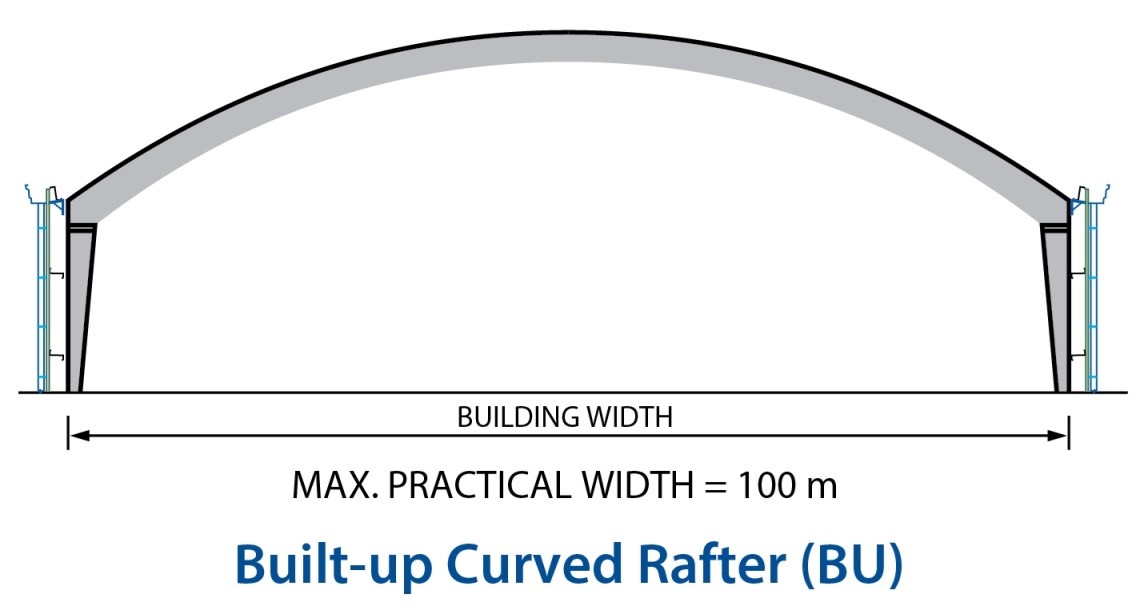

- Built-up Curved Rafter is a popular choice for construction projects such as warehouses, distribution centers, providing a sense of spaciousness and grandeur in public structures like airports, shopping centers, terminals, sports arenas, and entertainment centers.

Build up curved rafter in warehouse construction

Aircraft hangar constructed using curved built-up rafters by Pebsteel

3. Considerations for prefabricated warehouse construction

- Design: Select a well-balanced steel structure design that meets functionality, safety, durability, and aesthetics. Detailed design helps avoid cost overruns during execution.

- Material quality: Standard-quality materials ensure structural longevity and minimizes future maintenance expenses. Investing in quality upfront provides long-term benefits for the investor.

- Erection quality: Investors should spartner with reputable and experienced contractors to ensure the overall structural quality of the project. Additionally, ensuring safety during construction is a crucial requirement in prefabricated warehouse construction.

See more: Details of Construction Process Of Industrial warehouse

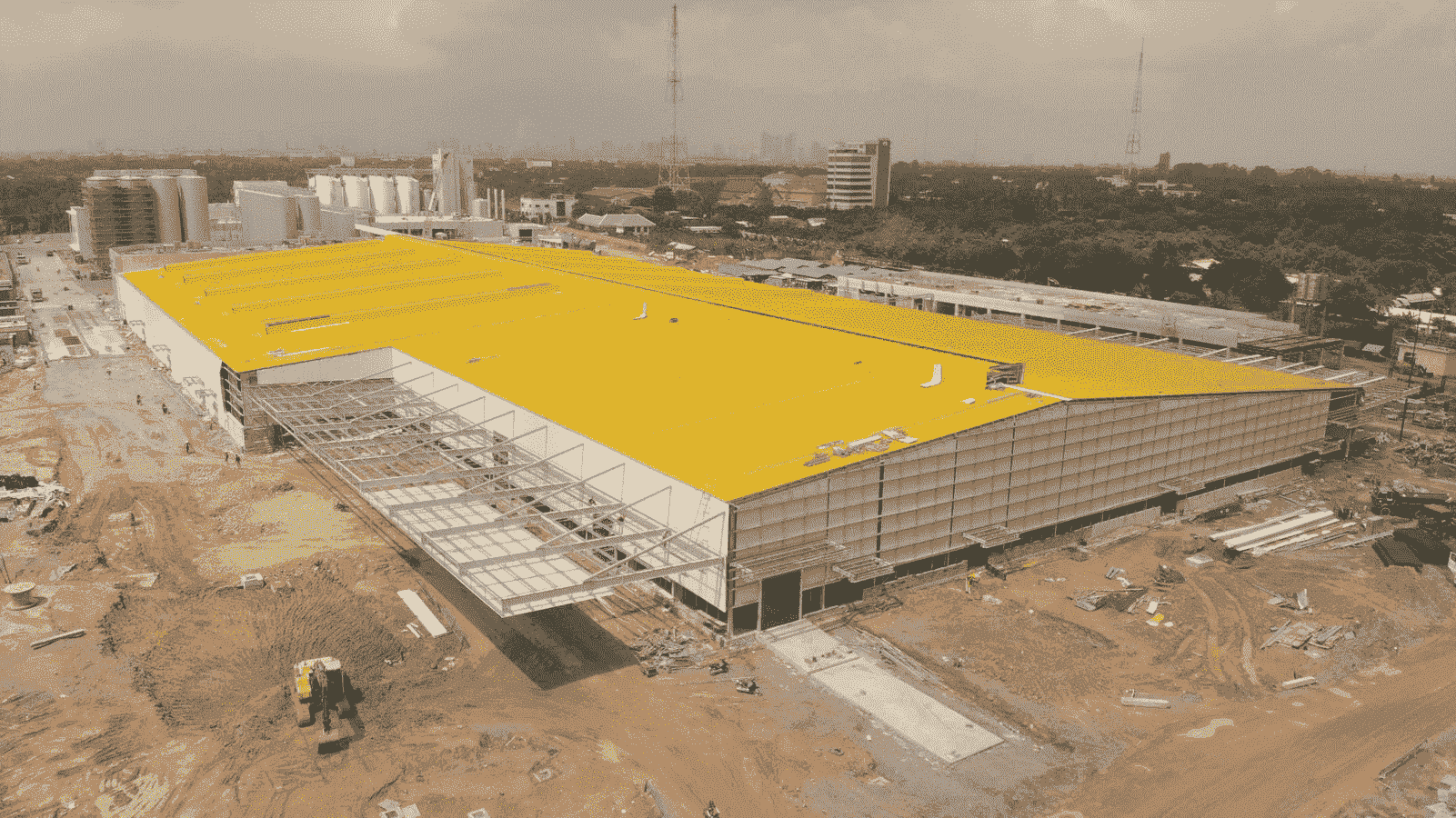

Pebsteel constructs prefabricated warehouse buildings

With over 31 years of experience in the prefabricated steel building industry, Pebsteel is committed to delivering high-quality, cost-effective solutions tailored to your project’s requirements. If you seek comprehensive solutions for Pre-Engineered Buildings or Structural Steel design, please contact Pebsteel via email at Marketing@pebsteel.com.vn or by phone at +84 908 883531 for immediate consultation.

More Information: Pebsteel Prefabricated Steel Buildings: Pioneering Green Construction

The prefabricated warehouse steel building constructed by Pebsteel

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.