Many people are familiar with prefabricated steel buildings (as known as prefab steel buildings) because nowadays this type of structure is becoming increasingly common. Prefab steel buildings are also highly favored to replace traditional reinforced concrete buildings thanks to the top benefits of steel structure building, and are widely used in warehouses, storage facilities, commercial centers, and even residential buildings.

1. What are Prefab Steel Buildings?

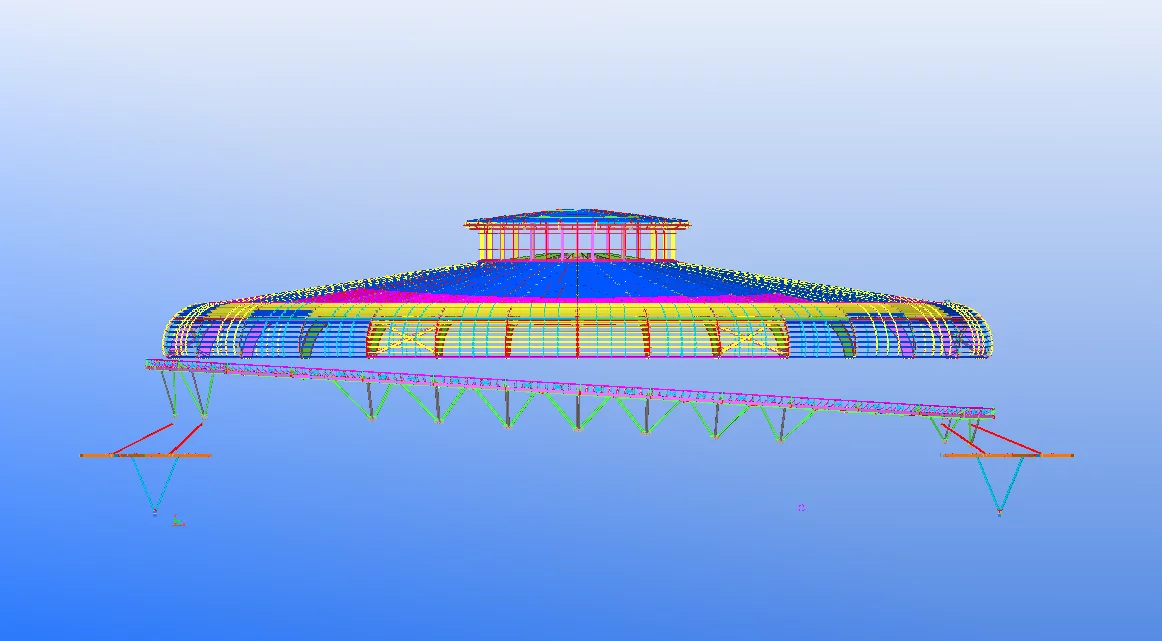

Prefab steel buildings are a type of structure constructed with standardized steel frame components, including columns, beams, purlins (walls and roof), galvanized steel sheets for walls and roof, and other accessories (trim, gutters, galvanized steel bracing cables, roof ridge vents, etc.), manufactured and assembled based on technical design drawings.

A complete prefab steel building goes through three main stages:

- Design.

- Production, fabrication of components.

- Installation at the construction site.

All the materials needed to construct a prefab steel building are prepared at the factory with precise dimensions and quantities, allowing transportation and construction to be carried out very quickly.

Prefab steel buildings for Electronic Component Parts by PEB Steel

2. Advantages of Prefab Steel Buildings

The entire process of implementing prefab steel buildings, from design, and fabrication to transportation and installation of steel structures, is carried out at significantly fast speeds. Furthermore, prefab steel buildings allow investors to maximize interior space utilization by using clear-span frames with widths of up to 180m (PEB Steel frame). When there is a need for design adjustments or scale expansions, investors can easily carry them out with prefab steel buildings without significantly affecting the main structure, optimizing implementation costs compared to traditional construction methods.

Prefab steel buildings have good load-bearing capacity and are lighter in weight than reinforced concrete buildings, helping reduce the load on foundations. As a result, investors can save costs on foundation reinforcement, construction materials, and labor.

The material used in the construction of prefabricated houses is structural steel. The steel used in steel frame houses has the biggest advantage of being sturdy, uniform, cost-effective and environmentally friendly.

3. Applications of Prefab Steel Buildings

Prefab steel buildings are commonly used for projects such as exhibition halls, shopping centers, cinemas, supermarkets, training centers, conference centers, multipurpose halls, hotels / resorts / restaurants, offices, sports centers, parking lots, public facilities (schools, hospitals, churches, temples, museums, exhibition halls, courts, etc.)

To obtain standard prefab steel buildings, investors should choose companies with many years of experience in steel construction, capable of providing comprehensive and optimal solutions from design to fabrication and installation, such as PEB Steel company with 31 years leading the market in Europe.

The footwear prefab steel building plant was designed and constructed by PEB Steel in Vietnam

4. Frequently Asked Questions about Prefab Steel Buildings

The above article summarizes the excellent applications of pre-engineered steel buildings. As a leading unit in the field of pre-engineered steel buildings with a quality process and experienced team, Pebsteel is ready to support and advise customers who need to construct and design pre-engineered houses via email at marketing@pebsteel.com.vn or phone number +84 908 883531.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.