1. Prefabricated steel building structure

1.1 Basic components of pre-engineered steel buildings

Prefabricated steel buildings include three main components:

– Main truss frame is a combination of “I” shaped steel columns and trusses.

– “Z” and “C” shaped galvanized purlins including roof purlins, wall purlins, gutter purlins.

– Roof and wall corrugated iron.

In addition, pre-engineered steel buildings also include auxiliary structures and accessories to ensure functionality and aesthetics according to the investor’s requirements:

– Auxiliary structures: mezzanine floors or intermediate floors (including beams and floors), crane beams (supporting the crane system), roof bracing, walkways,…

– Accessories and aesthetic details: decorative facades, canopies, extended roofs, decorative fascia panels, gutters, downspouts, galvanized tension cables, roof ventilation,…

All components of the pre-engineered steel buildings are manufactured and processed with precise dimensions and quantities at the factory, then transported to the construction site for assembly. Steel buildings are currently extremely popular as they help save construction costs for investors and significantly reduce completion time compared to traditional construction methods.

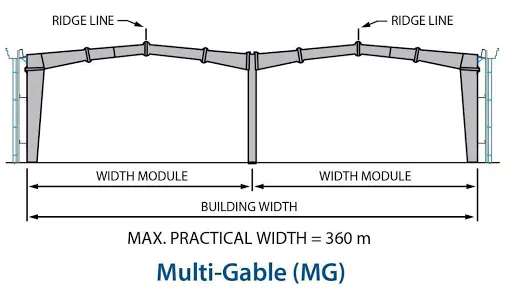

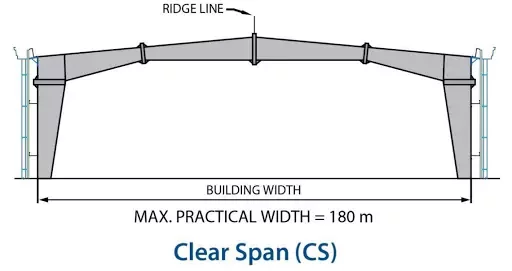

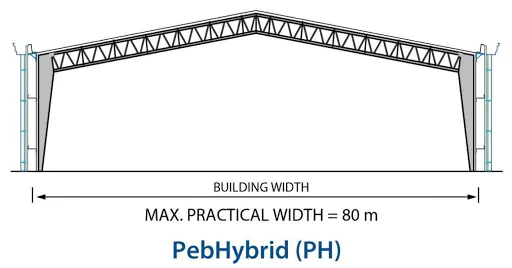

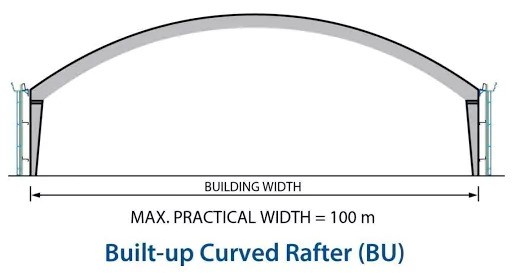

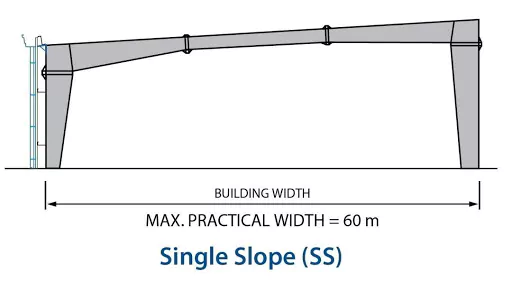

Depending on the usage needs, investors can choose the appropriate truss frame. Below are some typical truss frames by Pebsteel for pre-engineered buildings.

1.2 Auxiliary Structures of Pre-Engineered Buildings

To enhance the efficiency of both the interior and exterior of pre-engineered steel buildings, investors can equip additional auxiliary structures such as composite mezzanine floors, stairs, maintenance walkways, crane beams, etc.

Additionally, Pebsteel offers a variety of corrugated iron roofing sheets to meet different usage needs. For roofing systems, Pebsteel provides LokSeam® & PebSeam® sheets – types of sheets that do not require screws during installation and feature excellent water leakage resistance thanks to their lock and 360° seam design. Moreover, the PebWall® cladding wall sheet is a product that is not only sturdy but also provides high aesthetic value. For buildings with more than two floors, Pebsteel uses PebDek® decking sheets made of galvanized steel combined with reinforced concrete for the construction of composite floors.

2. Common Issues When Using Low-Quality Materials

Using substandard materials adversely affects the quality of the project, specifically:

– Low-quality truss frames: inadequate load-bearing capacity, poor corrosion resistance, posing potential hazards, especially directly affecting the overall safety of the structure.

– Low-quality purlins: prone to rust, poor load-bearing capacity, thus failing to effectively support the roof or wall panels.

– Low-quality metal-sheet roofing sheets: prone to rust, discoloration, leaks, easy cracking, poor heat reflection causing heat and stuffiness inside the building.

– Poor insulation foam or panels quickly deteriorate, leading to heat and mold issues.

– Low-quality gutters: causes waterlogging, blockages, and quick damage.

– Poor ventilation system: results in stuffiness, heat, and increased electricity consumption for air conditioning use.

3. Pebsteel’s Technology

To ensure the quality of each project and meet even the most complex customer requirements, Pebsteel continuously improves its processes and products while expanding its production scale through:

– 7 large factories in Vietnam and Myanmar, with a production capacity of up to 100,000 tons of steel per year.

– Modern machinery for material processing: CNC steel cutting, Plasma, Shearing; automatic welding machines; surface cleaning machines – metal spraying – automatic painting; roofing sheet roll-forming machines.

– Outstanding design and technical capabilities of more than 100 experienced engineers, applying international standards in design, processing, and construction: AWS 2015, IBC 2015, AISC 2016, MBMA 2012, AISI 2013; Tekla Structures, SAP, Strumis, ERP software.

– Raw materials imported from Japan, South Korea, and China with clear origins, all meeting ASTM (American) standards.

– All products are quality-checked at the factory after processing before being transported to the construction site: magnetic particle inspection (MPI), ultrasonic testing (UT), S.A 2.0 metal spraying, and steel surface protective painting.

– Strict supervision of the assembly process at the construction site.

– A 3-year warranty for materials and a 10-year warranty for structures.

Additionally, Pebsteel is constantly innovating in technology and working processes, updating modern methods to provide the best solutions for customers.

For consultation and to receive a free preliminary drawing, as well as the most suitable solution for your project, please contact us at tel: (+84) 908 883 531 or email: [email protected].