As industries continue to evolve, the demand for modern industrial buildings is steadily increasing. Steel structures have emerged as the optimal solution for contemporary factories, offering superior advantages compared to traditional materials. This article will delve into steel structures in industrial building construction to help you make informed decisions for your project.

What is a Steel Structure?

A steel structure is a system of steel members connected through bolts, rivets, or welding

A steel structure is a system of steel members connected through bolts, rivets, or welding to create a robust framework capable of bearing high loads. These structures are widely used across various construction sectors and serve as the backbone of industrial building construction.

Types of Steel Structures in Industrial Building Construction

2.1. Frame Structure: Beams and Columns

The frame structure consists of beams and columns. Beams transfer loads from floors to roofs and columns. They can measure up to 18 cm with spans ranging from 3m to 9m. Steel beams connect either to other beams or columns.

2.2. Grid Structures: Mesh or Dome Format

In this structural type, steel materials are assembled to form a grid pattern. The mesh roof creates a dome shape. This structure is commonly used in designing large-span buildings, such as greenhouse domes for agricultural or industrial production.

Construction of steel structure frame factory

2.3. Prestressed Structures

These structures utilize high-strength steel cables embedded in concrete. If external forces cause the steel cables to stretch, they counteract by reversing direction to resist external loads.

2.4. Beam Bridges

In large-scale factory projects with extensive production lines, beam bridges are designed to minimize manual labor. These are installed using dump cranes, and can also be mounted using dual supports.

2.5. Cable-Stayed Bridges

Industrial cable-stayed bridges were traditionally anchored to roof tower columns. The cables connect at a building pier point and run parallel down to the bridge deck, forming a harp-like tower pattern.

2.6. Truss Structures: Members or Trusses

Truss structures comprise interconnected steel members forming nodes. These members are joined using bolts, rivets, or welding.

Detailed structure of steel structures in factory construction

2.7. Arch Bridges

Steel arch bridges feature abutments at each end. The steel frame forms an arch shape. The bridge’s weight and load are converted into horizontal thrust forces transferred to both abutments.

2.8. Dome Architecture

Steel dome structures, with their long spans, are ideal for facilities like stadiums or factories. This structure consists of three main members connected in a zigzag pattern, typically utilizing galvanized round steel tubes.

2.9. Suspension Bridges

These structures are built using multiple horizontal or diagonal steel members. Key components include steel tower frames, suspension cables, main cables, anchors, and the deck. The main cables serve as support points for hanging anchor cables, connections, and deck support. They run parallel on both sides of the bridge deck and connect to the bridge tower frame peaks.

2.10. Truss Bridges: Truss Structure

Truss bridges are constructed using various steel frames with parallel frame outlines, polygonal edges, or parabolic shapes. Bridge members are connected using rivets or anchor bolts. The ground surface consists of horizontally crossed steel members reinforced with concrete.

Why Choose Steel Structures for Industrial Building Construction?

Steel structures are increasingly favored in industrial building construction due to their outstanding advantages. Here are the main reasons why you should consider steel structures for your industrial building project:

3.1. Durability and High Load-Bearing Capacity

Steel frames, manufactured from high-strength steel, offer exceptional load-bearing capacity and resilience against harsh environmental conditions such as rain, wind, storms, and snow. Additionally, steel structures provide superior durability and longevity, significantly reducing maintenance and repair costs over time.

3.2. Rapid Construction and Cost Efficiency

Steel structures are prefabricated in factories according to design specifications, then transported to the construction site for bolt-assembly installation. This streamlined construction process is:

- Simpler and faster compared to traditional materials

- Requires less labor

- Particularly suitable for projects with tight deadlines requiring quick completion and occupancy

3.3. High Design and Construction Flexibility

Steel structures can be easily bent, cut, and shaped, offering architects remarkable flexibility in design:

- Easy Size Adjustment: Steel components can be manufactured to precise specifications according to design drawings, optimizing usable space and minimizing material waste.

- Adaptable to Various Terrains: Thanks to their design flexibility, steel structures can adapt to complex terrains, including areas with weak soil conditions or subsidence issues.

- Easy Disassembly and Relocation: When necessary, steel components can be easily dismantled and relocated to new sites, saving both time and money.

High flexibility in the design and construction of steel structures

3.4. Easy Expansion Capability Future factory expansion is a common requirement. Steel structures excel in meeting this need through their flexible expansion capabilities. Expansions can be implemented in phases, aligning with investors’ financial capabilities.

3.5. Enhanced Safety Features

- Superior Load-Bearing Capacity: Made from high-strength steel, these structures can withstand significant loads and ensure building safety in all weather conditions, including extreme weather events like storms and typhoons.

- Fire Resistance: Steel frames with galvanized or powder-coated finishes minimize fire risks. Additional fire alarm and suppression systems can be installed for enhanced safety.

- Lightning Protection: Steel structures’ excellent electrical conductivity provides natural protection against lightning strikes.

3.6. Environmental Sustainability Modern steel production processes are increasingly refined to reduce emissions and environmental waste. Furthermore, steel structures are recyclable, contributing to natural resource conservation.

3.7. Optimized Space Utilization

- Steel structures are thinner than traditional building materials like reinforced concrete, maximizing buildable area and increasing usable interior space.

- Allows for high vault designs and slender columns, creating spacious, well-ventilated areas ideal for machinery movement and inventory storage.

Steel structure increases space utilization efficiency

3.8. Reduced Maintenance Costs

- Steel structures offer high durability, excellent rust resistance, and protection against pest infestation.

- Smooth steel surfaces are easy to clean and maintain, reducing labor and cleaning material costs.

3.9. Enhanced Architectural Aesthetics

- Steel structures can be finished in various colors, creating a modern, sophisticated appearance for industrial buildings.

- The versatility of steel structures enables architects to create unique, attractive factory designs that stand out.

Advantages of steel structures in industrial factory construction

When to Choose Steel Structures for Industrial Building Construction?

The choice of construction materials for industrial buildings depends on various factors such as area, budget, usage requirements, and environmental conditions. Steel structures emerge as an optimal solution for many modern factories. Here are typical scenarios when steel structures are recommended:

- When rapid construction is required

- When cost efficiency is a priority

- When high durability is needed

- When future expansion is anticipated

- When aesthetic appeal is important

- For large-scale facilities requiring wide spans

- For buildings requiring heavy machinery installation

- For construction on weak soil foundations

- For construction in harsh weather conditions

Steel Structure Implementation Process in Industrial Building Construction

5.1. Design Phase

- Drawing Design: Engineers and architects create detailed building designs, including main frames, roofing systems, electrical, plumbing, and ventilation systems.

- Steel Material Selection:

- Choose appropriate steel grades meeting technical requirements, including steel grade, thickness, and dimensions

- Consult reputable steel suppliers to select high-quality materials at reasonable prices

- Load Calculation:

- Calculate various loads affecting the building, including dead loads, snow loads, wind loads, and dynamic loads

- Determine appropriate dimensions and spans for beams, columns, and trusses to ensure structural integrity

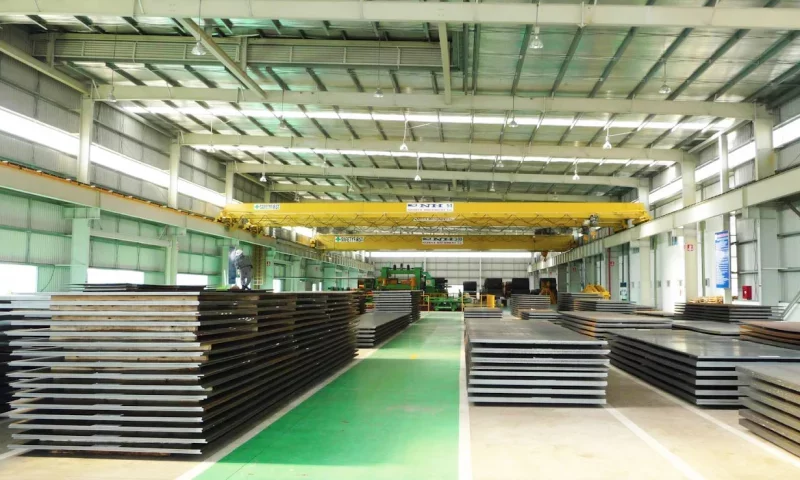

5.2. Manufacturing Phase

- Steel Cutting:

- Cut steel plates and sections according to design specifications

- Utilize specialized cutting equipment like plasma cutters and CNC machines for high precision

- Assembly Setup:

- Align steel components according to design drawings to form complete structural elements

- Use specialized fixtures like clamps and welding jigs to ensure accuracy and safety

- Welding:

- Join assembled steel components using manual arc welding, submerged arc welding, or electron beam welding

- Employ skilled welders using proper equipment and following safety protocols

- Verify weld quality through ultrasonic testing and visual inspection to ensure structural integrity

- Straightening:

- Adjust steel components after welding to ensure straightness and prevent warping or shrinkage

- Use specialized straightening equipment like hydraulic straighteners

- Verify accuracy using professional measuring devices

- Surface Preparation:

- Clean steel surfaces using sandblasting or chemical cleaning to remove dirt, rust, and grease

- Ensure surfaces are clean and bright before painting or galvanizing

- Painting or Galvanizing:

- Apply paint or galvanize steel surfaces to protect against environmental factors like oxidation and corrosion

- Select appropriate coating materials based on environmental conditions

- Follow proper technical procedures to ensure durability and aesthetics

Steel structure production stage in factory construction

5.3. Construction Phase

- Site Preparation:

- Level the ground and create solid foundations

- Install pile systems and foundation beams according to design specifications

- Frame Assembly:

- Use tower cranes to transport and erect steel components according to design plans

- Connect steel components using bolts, rivets, or welding

- Verify accuracy and safety of the assembled frame

- Roof and Auxiliary Systems Installation:

- Install metal sheets, tiles, or reinforced concrete roofing as per design

- Set up electrical, plumbing, ventilation, and fire protection systems

- Test all auxiliary systems before commissioning

- Completion and Acceptance:

- Clean the construction site thoroughly

- Inspect building quality according to regulations

Steel structure construction phase

Important Considerations When Using Steel Structures in Industrial Building Construction

While steel structures offer superior advantages like rapid construction, cost efficiency, and high load-bearing capacity, several crucial factors must be considered to ensure quality, safety, and effectiveness:

6.1. Steel Material Selection

- Use high-quality steel that meets technical specifications for grade, thickness, and dimensions

- Choose reputable suppliers with proper documentation of origin and quality certifications

- Thoroughly inspect steel quality before use

6.2. Steel Structure Design

- Design drawings must be created by experienced, qualified structural engineers

- Designs must meet requirements for durability, safety, load-bearing capacity, aesthetics, and client needs

- Carefully calculate all loads affecting the building (dead loads, snow loads, wind loads, dynamic loads)

- Select appropriate dimensions for beams, columns, and trusses to ensure structural integrity

6.3. Construction Implementation

- Strictly follow steel construction procedures according to building standards

- Use specialized construction tools to ensure accuracy and safety

- Employ skilled workers proficient in equipment operation

- Inspect quality of welds, bolts, and rivets after installation

- Maintain workplace safety throughout construction

6.4. Steel Structure Maintenance

- Properly maintain steel structures post-construction to prevent rust and corrosion

- Apply paint or galvanizing for surface protection

- Conduct regular inspections and maintenance to ensure long-term durability and safety

6.5. Additional Considerations

- Select reputable contractors with experience in steel structure industrial buildings

- Maintain strict supervision during construction to ensure quality and timeline compliance

- Conduct thorough inspection before project handover

Note when applying steel structures in industrial factory construction

The application of steel structures in industrial building construction offers numerous benefits for investors. However, ensuring quality, safety, and effectiveness requires strict adherence to technical requirements and attention to important details. We hope this article has provided you with a basic understanding of steel structures in industrial building construction!

For comprehensive solutions in warehouse and steel factory construction, contact Pebsteel via email at [email protected] or phone: (+84) 908 883 531 for immediate consultation.