The price quoting process plays an important role that customers need to carefully consider before investing to construct. Join Pebsteel to refer to factors that affect the unit price for constructing the civil steel-frame buildings in 2024.

1. Construction costs for steel-frame buildings

Steel – frame buildings in general and civilian houses in particular will have the price quotes that depend on many factors, typically, are structural demands or scale construction. Besides, the construction costs also fluctuate over time, or by the building materials.

1.1 According to the type of civil steel-frame buildings

Depending on the type of civil steel-frame houses, the customers demand the scales as well as unsimilar loads; unit-price norm for construction will also have differences. Typically is public buildings (schools, museums, stadiums, etc), which need to have large space, and good load bearing capacity. With this type of construction, the construction organization needs to use loads-bearing steel frame with column, rafter, beam which have bigger size in comparison with the small housing constructions. For the type of houses, the structural scale also greatly affects the construction costs.

1.2 According to the details of categories

Nowadays, the standard price-quoting table of civil-framed houses has 4 main categories including foundation structure, framing, sheeting, and accessories.

1.2.1 Costs for foundation

Civil steel-frame houses still use concrete to build the foundation structure. This cost level is synthesized in a cost package including foundation materials, and labor costs.

1.2.2 Costs for framing

For civil steel-frame houses, most of the building materials are steel. Depending on how the rafter frame that the construction uses is, as well as technical requirements for different steel frame systems leading to different cost levels.

1.2.3 Costs for sheeting

Cost for the roof system will be applied for metal-sheet walls and metal-sheet roofs. In addition to the common feature of shielding, there are various types of iron sheets which have special features; such as leak-proof irons, tornado-resistant irons, heat-resistant irons, auto-exposure irons, and decorative irons. So the costs of a roof system depend on the type of iron roofs , the material steel structure of producing irons, demands for aesthetics (color, decoration,…)

1.2.4 Costs for sub-structural system

To increase aesthetics, improve features like air ventilation, creating side aisles, sunshades for civil steel-frame houses; the substructure system will include items such as roof, roof top ventilation, crane, stairs.

This table includes basic categories for constructing pre-engineered steel houses:

| Ordinal Number | Construction Categories | Basic building materials (according to some construction units) | The products provided by Pebsteel |

| 1 | Foundation structure, base course | – Footing: concrete lining, iron, concrete foundation.- Foundation: stone aggregation, PVC tarpaulin, concrete stone base, plastering.- Wall: bricks, cement, sand, paint. | |

| 2 | Framing | – Rafter framing- Purlin- Brace- Bracing cable | – Rafter frame: clear-span, multi-span, roof system, single slope, PebHybrid rafter, Lean-to rafter, Built-up curved rafter, multi-gable, multi-floor.- Bracing system |

| 3 | Sheeting | Metal sheet roof, metal sheet wall, exposuring metal sheet, heat-proof material, decorative metal sheet | Walls and roofs: LokSeam®, PebLiner™, PebWall®, PebDek®, PebSham 128®, PebRoof®, load-bearing purlin. |

| 4 | Sub-structural system | Bulkhead, bulkhead bracket, platform, staircase, roof purlins, and wall purlins with the shapes of letter C and Z… | Canopy, fascia, crane, ridge ventilator, steel hinge, ladder, grating floor, staircase railing, staircase, aisle, roof sheeting |

1.3 Main materials/steel components for a sample of pre-engineered steel building

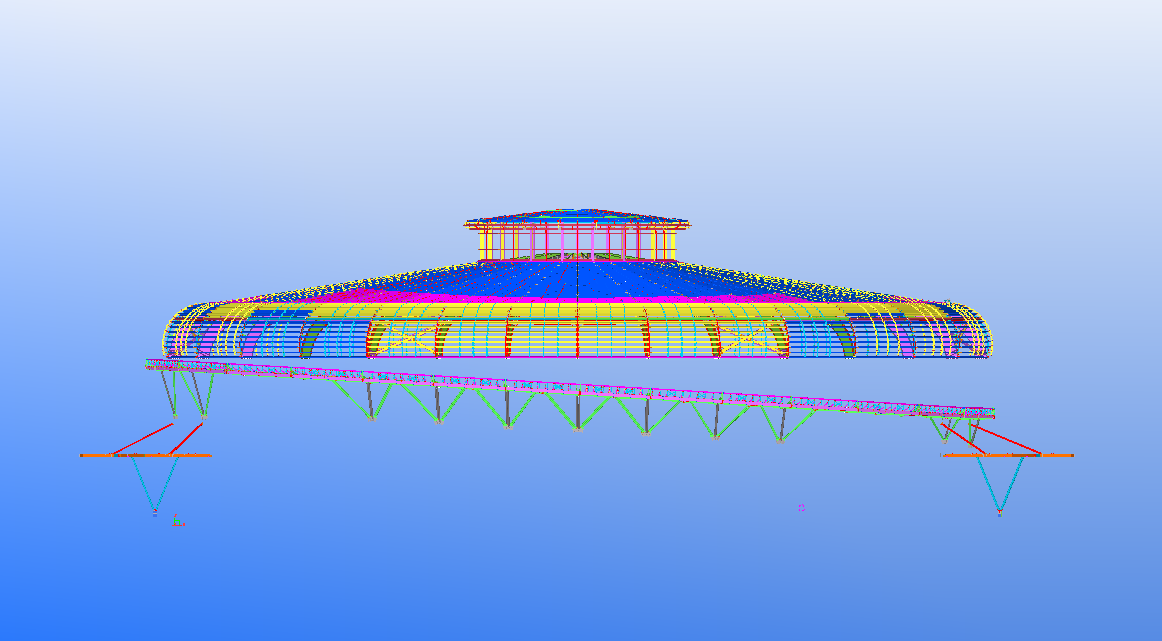

In 2016, Pebsteel completed a civil building with pre-engineered steel frame in the Philippines. This is a civil steel-frame construction up to 1000 meters square wide to serve the accommodation for employees.

2. Price quoting process of pre-engineered steel houses by Pebsteel

Pebsteel is the most reputable company that designs, constructs pre-engineered buildings nowadays. Having developed for 27 years in Asia, constructed more than 6000 pre-engineered buildings in various countries, Pebsteel is proud to satisfy the customers’ demands of building pre-engineered buildings with optimized construction costs.

The price quotation process of Pebsteel is always explicit, clear, and full of details:

- Consulting: First, the company will learn in details about customers’ demands to generally deploy the drawings, and developing ideas about solutions, materials; also suitable price quotation. After the customers have referred to the price quotation of pre-framed houses and accepted it, Pebsteel will deploy to quote the final price, and start deploying the plan.

- After the contract: After two sides have confirmed the price quotation, signed the contract, Pebsteel will deploy the detail drawings, begin the procedure, and then erect (based on the drawings).

With the professional process of price quotation above, Pebsteel assures to provide customers with an exact price quote to optimize the customers’ demands.

3. Factors affecting the construction costs of civil steel-frame houses

When building pre-engineered buildings, depending on the construction scale, and some objectives that affect the erection costs. Some criteria affecting the price quotation of steel-frame houses that customers need to pay attention to, including:

3.1 Structure

Building scale, designing style are the top factors that directly affect the structure of construction, and construction costs. If the housing construction has complicated structure, multi-floor, various functional areas; which need to carefully focus on bearing-load problem. This relates to the quantity supplied such as column components, beams, floors is required to use to ensure the house’s reliability. All of these things will change the construction costs to ensure the quality.

3.2 Materials

Besides using pre-engineered steel materials (structural steel), steel-frame buildings also use other materials like concrete for foundation, glass windows, iron roofs,…Depending on the demands of customers, the construction unit will choose to use suitable type, quality leading to different-changing costs.

3.3 Construction conditions

Unstable pre-engineered construction conditions will affect factors such as lengthening the erection time, increasing the labor costs,…then affecting the construction costs. Some factors such as construction location far from center, which leads to the difficult forwarding process of materials, long distance… All of them affect the construction costs of steel-frame buildings.

4. Some beautiful pre-engineered steel buildings

Above is the latest details of the price-quotation process of civil steel-frame buildings in 2024, as well as some great pre-engineered steel building samples by Pebsteel. If any customers need a consultation, assistance in a detailed price quotation for warehousing construction, contact Pebsteel at email marketing@Pebsteel.com.vn or make instant calls at hotline +84 908 883531 for direct consultation.

Common questions about civil steel-frame buildings

What are civil steel-frame buildings?

Civil steel-frame buildings are the type of civil building such as public works, schools, museums, houses which are built with standard pre-engineered steel frame including parts as following: column framing system with rafters, purlins (roof, wall) zinc galvanized, metal-sheet walls, metal-sheet roofs, and other accessories (trims for decoration, gutters, bracing cables galvanized with zinc, rooftop ventilators…) manufactured, and erected based on technical drawings.

How to optimize the construction costs for civil steel-frame buildings?

The investors, who want to optimize the construction costs of steel-frame buildings, need to understand the purpose of construction, as well as construction criteria to ensure the highest accuracy of technical drawings, and the amount of materials used. This is to prevent all costs incurred during the construction process. Specifically the costs of additional materials, as well as the procedure costs, and erection. In addition, a professional construction partner can help investors ensure the quality of the work, the construction schedule, as well as the strict cost estimation from the beginning.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.