The agricultural sector in Vietnam is experiencing robust development, necessitating the application of modern, efficient, and cost-effective construction solutions. Pre-engineered buildings have emerged as an optimal choice for agricultural projects due to their superior advantages. This article will delve into analyzing the diverse applications of pre-engineered steel buildings in constructing factories, warehouses, and agricultural facilities, while also sharing practical benefits and important considerations when using this type of material:

1. What is a pre-engineered steel building?

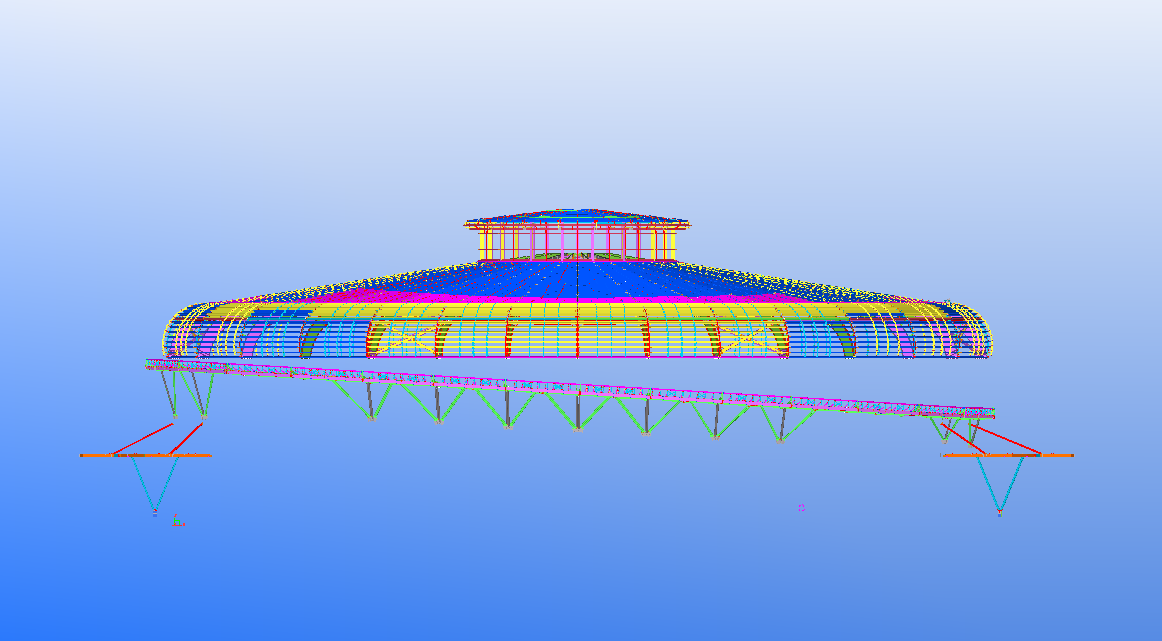

A pre-engineered steel building is a type of structure designed, fabricated, and assembled using standardized components and methods before being transported to the construction site. The design of these projects is often referred to as steel structure design.

These buildings are designed to meet specific requirements and are manufactured off-site, allowing for faster and more efficient construction. Steel components include main frames such as columns, trusses, beams; secondary structural systems including purlins, wall top struts, wall beams, etc., and cladding systems and accessories such as roof panels, wall panels, etc.

The pre-engineered steel building construction process involves three main stages:

1. Design: Engineers calculate and design steel components for the project based on usage requirements, terrain, and climatic conditions.

2. Component fabrication: Steel components are fabricated and tested in factories according to the design drawings using modern machinery to ensure high accuracy.

3. On-site assembly: Steel components are transported to the construction site and assembled according to predefined sequences.

Animal Shed, Cambodia

2. Advantages of pre-engineered steel buildings in agricultural projects

Pre-engineered steel buildings are increasingly being widely applied in agricultural construction due to their numerous significant advantages over traditional building types such as wooden houses, or basic buildings. Below are the key advantages that make pre-engineered steel buildings the top choice for agricultural projects:

2.1. Increasing the productivity of crops and livestock

- Effective environmental control: Thanks to their flexible design, pre-engineered steel buildings allow for adjusting environmental conditions such as temperature, humidity, and light inside, suitable for different types of crops and livestock, optimizing the growth and development process.

- Minimized adverse weather impacts: The robustness of pre-engineered steel buildings protects crops and livestock from adverse weather conditions such as heavy rain, storms, salt mist, etc.

- Disease prevention: Environmental control and limited direct contact with the outside environment help minimize the risk of disease outbreaks among livestock.

2.2. Cost-saving in operation

- Energy efficiency: The excellent insulation capability of pre-engineered steel buildings reduces heat loss, thereby contributing to cost savings for the heating or cooling systems.

- Reduced repair costs: The durability and high load-bearing capacity of prefabricated steel buildings help minimize the risk of damage, thus reducing the need for frequent repairs.

- Material reuse: Steel components can be reused when dismantling buildings, saving costs and being environmentally friendly.

2.3. Corrosion resistance

The anti-corrosion ability of pre-engineered steel buildings is one of the important factors that help increase the longevity and durability of the building, especially in agricultural environments, where they are often exposed to corrosive factors such as chemicals, high humidity, and harsh weather conditions. Factors that create corrosion resistance:

Using high-quality steel materials: Prefabricated steel buildings are often made from galvanized steel or stainless steel, which are naturally highly resistant to corrosion. The zinc coating protects the steel surface from corrosive agents such as water, air, and chemicals commonly found in agricultural environments.

Protective coating: After galvanizing, the steel is also covered with an additional layer of anti-corrosion paint, which enhances the ability to protect the steel surface, preventing the impact of environmental factors.

Precise design and assembly: Prefabricated steel buildings are designed and assembled with high precision, minimizing gaps and weak spots where corrosion can occur.

2.4. Moisture resistance

Moisture resistance is a significant advantage of pre-engineered steel buildings, particularly in agricultural projects where high humidity is a persistent issue. Key factors contributing to their mold resistance include:

Waterproof material: Steel is a waterproof material, helping to prevent the penetration of water and moisture inside the structure, thereby preventing the growth of mold.

Effective ventilation and drainage system: Prefabricated steel buildings are often designed with good ventilation and drainage systems, helping to control humidity inside the building.

Use moisture-proof materials: In addition to steel, other auxiliary materials such as moisture-proof paint, insulation, and moisture-proof materials are also used to enhance mold resistance.

2.5. Expanding business opportunities

- Facilitating year-round production activities: With good environmental control capabilities, pre-engineered steel buildings allow agricultural production activities to take place throughout the year, irrespective of adverse weather conditions.

- High-tech agriculture development: Pre-engineered steel buildings provide an ideal platform for applying advanced agricultural technologies such as hydroponics, aeroponics, etc.

- Drawing visitor attention: Contemporary and distinctive designs of pre-engineered steel buildings possess the ability to captivate visitors, fostering the potential for agricultural tourism growth and development.

2.6. Contributing to sustainable agriculture development

- Water resource conservation: Automatic irrigation systems can be installed in pre-engineered steel buildings to save water and reduce waste.

- Renewable energy use: Solar energy can be utilized to provide power for pre-engineered steel buildings, minimizing environmental impact.

- Reducing agricultural waste: The effective environmental control systems in pre-engineered steel buildings contribute to the reduction of agricultural waste and preserving the environment.

2.7. Optimizing production space

Traditional construction projects often necessitate large concrete columns, occupying significant space. Pre-engineered steel structures address this issue by requiring minimal space for construction materials, allowing more room for production activities.

2.8. High durability and load-bearing capacity

- The house frame is made of galvanized steel or electrostatically painted steel, which is resistant to rust, termites, and can withstand harsh weather conditions such as rain, wind, storms, etc.

- Sturdy steel structure, capable of bearing heavy loads, suitable for large-scale projects requiring spacious areas to store machinery, equipment, agricultural products, etc.

2.9. Flexibility in design and expansion

- Pre-engineered steel buildings can be designed with various styles and patterns to meet the diverse usage needs of households, farms, cooperatives, etc.

- Easily expanding the area in the future by incorporating additional frames and roofing. This adaptability facilitates prompt decision-making and mitigates disruptions to agricultural productivity.

Prefabricated steel buildings are flexible in design and expansion

2.10. Minimal maintenance required

Most traditional agricultural construction projects are made of wood. However, wood is not weather-resistant.

Within a few years, wooden structures can deteriorate and require maintenance such as painting or refurbishing materials, making pre-engineered steel buildings a highly considerate option.

2.11. Excellent fire resistance capability

- Galvanized or electrostatically painted steel frames minimize the risk of fire and explosions.

- Supplementary fire Alarm and firefighting systems can be installed to ensure optimal safety measures for the structure.

2.12. Easy cleaning and maintenance

Pre-engineered steel buildings featuring smooth steel surfaces offer ease of cleaning and maintenance. Moreover, their inherent resistance to termite and insect infestations minimizes the risk of damage to agricultural products and materials.

Benefits of applying prefabricated steel buildings in the construction of agricultural facilities

3. Common uses of pre-engineered steel buildings in constructing agricultural factories, warehouses

As outlined in this steel building guide, the pre-engineered steel building construction process involves three main stages:

3.1. Construction of processing plants for agricultural products

- Food processing: Pre-engineered steel buildings are utilized for constructing food processing plants for various agricultural products such as vegetables, fruits, meat, dairy, etc. ensuring adherence to safe and hygienic processing procedures.

- Livestock feed production: Pre-engineered steel buildings are utilized for constructing livestock feed production facilities, following modern processes to ensure the quality and nutritional value of animal feed.

- Raw material processing: Pre-engineered steel buildings are employed for constructing processing plants that convert agricultural raw materials such as cotton, sugarcane, rubber, etc. into high-value economic products.

Construction of factories and agricultural product processing plants

3.2. Construction of storage warehouses

- Agricultural product storage: Pre-engineered steel buildings are used for warehouse construction to store post-harvest agricultural products such as rice, corn, sweet potatoes, etc., in optimal conditions to prevent losses and damage.

- Fertilizer and chemical storage: Proper storage of fertilizers, pesticides, and chemicals is essential and compliant with regulations in agriculture. Pre-engineered metal buildings can be customized to meet storage requirements.

- Equipment storage: Pre-engineered steel buildings are used to construct warehouses for storing various agricultural equipment, tools, fertilizers, pesticides, etc.

- Cold storage: Pre-engineered steel buildings are used to construct cold storage facilities for preserving food and agricultural products at low temperatures, extending their shelf life.

- Garages and vehicle storage: Farmers often use these buildings as metal garages or metal storage sheds for personal vehicles and as additional storage space for small equipment, tools, and supplies.

Constructing storage warehouses using prefabricated steel

3.3. Installation of farm sheds

- Livestock sheds: Pre-engineered steel buildings are used to construct sheds for various livestock such as pigs, poultry, cattle, goats, etc., ensuring a safe and hygienic living environment, limiting disease outbreaks, and improving livestock productivity.

- Milking area: Prefabricated steel buildings are used to construct milking areas for dairy cows, ensuring food safety and hygiene standards for the milk production.

- Hatchery area: Prefabricated steel buildings are used to build hatchery areas for chicks, maintaining the appropriate temperature and humidity conditions for the hatching process.

3.4. Greenhouses

Prefabricated steel buildings can be adapted for use as greenhouses. They provide a controlled environment for growing plants, vegetables, and flowers, enabling year-round cultivation and an extended growing season.

3.5. Agricultural Offices

On larger farms or agricultural business facilities, prefabricated steel buildings can house administrative offices and provide workspace for farm staff and management.

4. Key considerations for applying prefabricated steel buildings in the construction of agricultural facilities

4.1. Choosing a reputable supplier

- The quality of pre-engineered steel buildings largely depends on the quality of steel components. Therefore, it is crucial to choose a reputable supplier with experience in manufacturing and constructing pre-engineered steel buildings in the agricultural sector.

- Gathering feedback and opinions from individuals who have previously utilized pre-engineered steel buildings can offer valuable information and insights to aid in the selection process of a suitable supplier.

4.2. Design tailored to usage needs

- It is essential to clearly define the intended usage of the pre-engineered steel building to ensure a suitable design. For example, if used for food processing plants, a well-designed ventilation system is necessary, while for agricultural storage facilities, an appropriate preservation system should be designed.

- Consulting with structural engineers and architects can lead to the most optimal design for the project.

4.3. Selecting appropriate materials

- There are various materials available for pre-engineered steel buildings such as galvanized steel, powder-coated steel, corten steel, etc. Each material has its own advantages and disadvantages, so selecting the most suitable material based on usage conditions and project budget is crucial.

- It is advisable to seek input from the supplier to choose the most suitable materials.

4.4. Proper construction techniques

- Construction of pre-engineered steel buildings should be carried out by a skilled and experienced team of workers.

- Adhering to technical requirements during construction is essential to ensure quality and safety for the structure.

4.5. Maintenance and periodic upkeep

- Pre-engineered steel buildings require regular maintenance and periodic upkeep to ensure their durability and useful life span.

- Periodic cleaning of the steel components, as well as inspection of the lightning protection and waterproofing systems, are essential.

- Periodic maintenance should be performed in accordance with the recommendations from the supplier.

Additionally, attention should be paid to the following factors:

- Load capacity: Accurate calculations of the building’s load requirements are essential for selecting a steel frame with the appropriate load-bearing capacity.

- Environment: Appropriate materials and design must be selected to suit the environmental conditions of the construction site.

- Legal: Obtaining a construction permit is required before installing prefabricated steel buildings.

Considerations for the application of prefabricated steel buildings

Based on the information and considerations above, we hope you will choose and effectively utilize pre-engineered steel buildings for your agricultural construction projects. If you are seeking comprehensive solutions for building pre-engineered steel warehouses and factory buildings, please feel free to contact Pebsteel via email at marketing@pebsteel.com.vn or hotline (+84) 908 883 531 for immediate consultation today.

Please contact Pebsteel via … for detailed advice and guidance on steel frame house construction, as well as to view our complete steel frame house construction process using the most advanced technology.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.