The choice of steel materials is a very important issue, which determines the durability and solidity of constructions in general and prefabricated buildings in particular. There is a lot of iron and steel on the market nowadays. In which synthetic steel is a material used quite commonly and highly applicable. So what is this material that stands out and should be chosen? Join Pebsteel to find out more about the definition, features and classification of synthetic steel in the article below.

1. What is the definition of synthetic steel?

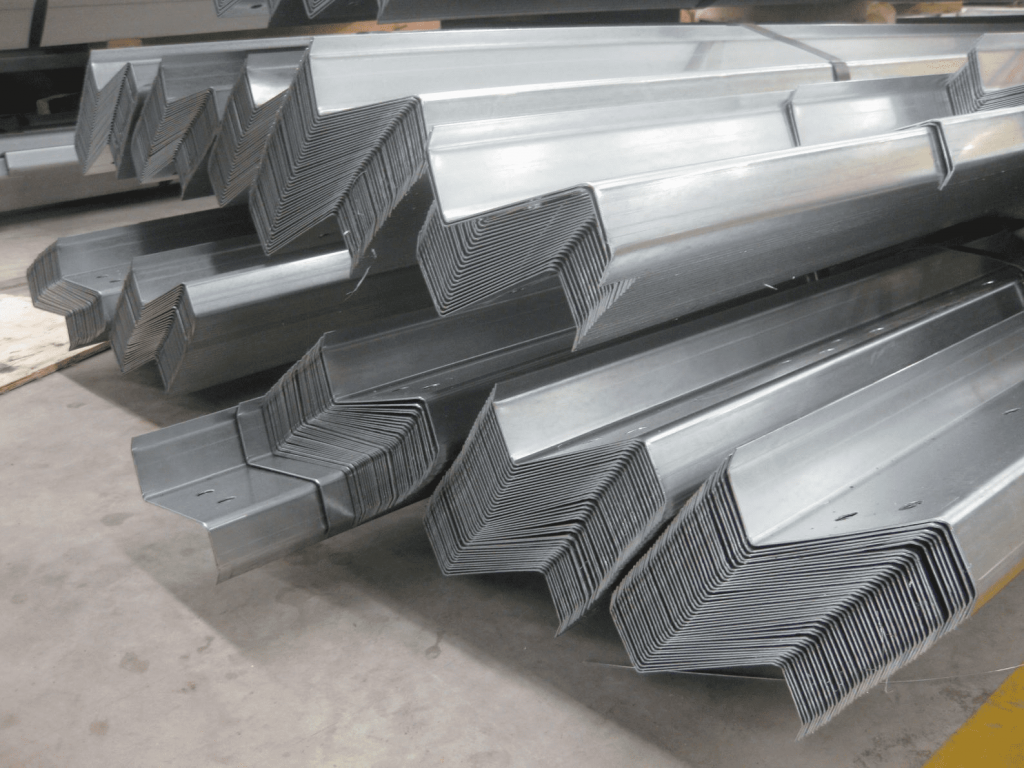

Synthetic steel is the type of material which is cut out of sheet steel, after that they are recombined into steel shaped by shape and size in the technical drawing. The steel plates cut from the steel billet are then linked together by welds to create components of a specific size. Accordingly, most of the molded steel products have almost no diverse sizes such as synthetic steel.

The design, size and thickness of the synthetic steel is unlimited, suitable for many constructions and requirements of customers. Synthetic Steel has a solid structure, good bearing capacity, so the construction process is carried out quickly and helps to optimize material costs.

>>Read More: What is a Steel structure? Main type of steel structure building!

2. Features of synthetic steel

The main shape of synthetic steels nowadays is usually H-shaped steel and I-shaped steel. However, with the feature of being combined from sheet steel, customers can completely book the fabrication of this material according to the desired shape and size. Here are some of the highlights of steel combinations:

- Large sizes and diverse designs: Conventional molded steel products have a limited style and size, which does not meet the technical requirements set out with many constructions. Synthetic steel can overcome this situation because it can be fabricated according to its own technical requirements.

- Withstanding heavy loads: The synthetic steel has good quality, heavy load bearing capacity and extremely small tolerance. Therefore, it can meet the technical requirements for both heavy industrial constructions that require certainty.

- Low hammock: Due to the large steel size plus the steel body is longer than conventional steel, the curvature of the hammock can be well controlled

- Light weight, material and cost savings: Thanks to being fabricated according to the specific technical requirements of each project, synthetic steel helps investors save the amount of used materials, which means optimizing construction budget.

3. Classification

Each customer and each construction will have their own requirements and features of materials. Therefore, the synthetic steel products on the market nowadays are also very diverse in terms of size, shape and application. They are also classified in many different ways, but the most common classification is by division. Accordingly, the synthetic steel will include the following types:

- U-shaped steel beams: The product has a U-shaped cross section. The height of the wings is moderate compared to the width of the steel body.

- I-shaped steel beams: The product has an I-shaped cross section. In some special cases, H-shaped steel beams are also considered to be I-shaped steel beams.

- V-shaped steel beams: The product has a V-shaped cross section. Two steel wings are equally wide.

- L-shaped steel beams: The product has an L-shaped cross section. The single wing width is less than the steel body length.

4. Production process

The process of fabricating and producing synthetic steel requires high accuracy, including the following steps:

Checking input materials

This is a very important first step to control and create high-quality synthetic steel products. The steps to perform the test include:

- Checking the origin of materials and quality records.

- Comparing and contrasting the features of the material with the technical requirements of the project.

- Comparing materials with current construction industry standards.

- Cutting the sample to check the quality. If it is requested for designation, use a third-party laboratory to conduct the test.

- Checking the results of the experiment, if the quality is guaranteed then it will be put into production.

Steel cutting

Depending on the equipment at the fabricating facility, steel plates can be cut by using methods such as CNC plasma cutting machine, hole stamping machine,…… Then the odd steel plates are straight pressed , cut to form steel components into the shape of H, I, V, U, L … based on the requirements of the original drawing.

Synthetic weld

The wings and abdomen of the steel after being cut to the required size are welded automatically by machine. . Steel components need to be surface tested, magnetically tested and ultrasonic tested… to ensure the weld is technically correct and has a good quality.

Checking and adjusting

Steel components after being welded need to be checked, straightened and re-aligned to restrict warping and errors in welding at high temperatures.

Gusset plates welding and ribs reinforcement

These parts will be welded by hand to ensure absolute accuracy. This stage requires technical welders to have certificates, experience and high skills to ensure technique and quality.

Surface cleaning and ball spraying

After the welding process, the synthetic steel component will be cleaned and treated by surface rust with a ball sprayer before entering the process of painting to protect the steel surface.

Read more: Structural Steel: Types, Properties, And Applications

Coating paint

The synthetic steel will be coated with surface protection paint, which includes fireproof, corrosion-resistant paint and decorative color paint.

The synthetic steel production process requires the implementation organization to have high expertise and modern facilities. Therefore, the investor should consider the selection carefully or consult the advice from construction organizations. With extensive experience and a team of qualified engineers, Pebsteel is always ready to support and provide you with convenient and quality construction services.

Here’s the information related to synthetic steel. If you still have questions that need to be answered and designed to build an industrial construction, please contact at the following email: marketing@pebsteel.com.vn or phone number +84908 883531 for specific advice.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.