Factory metal roofs play an important role in industrial buildings, especially prefabricated steel buildings, providing protection and comfort to the production process. With features such as waterproofing, bearing capacity and fire resistance, the factory metal roof not only provides cover but also ensures safety and efficiency for business activities. Pebsteel invites you to learn about the 6 most popular types of factory roofs in the following article.

See more: What is the Crane? Classification and Application in Constructions

1. The importance of factory metal roofs

The corrugated iron roof is one of the important factors in the factory structure, affecting the quality and efficiency of the building. Factory roofs are commonly made of different materials.

Factory metal roofs have many benefits, such as:

- Protect the building from external factors such as wind, rain, sun, dust, etc.

- Maintaining conditions of temperature, humidity, light and air on the construction site, affecting the production process and the health of our workers.

- Saving on energy costs, reducing noise, and providing anti-rust and anti-chemical protection.

- Therefore, choosing the right type of corrugated iron roof for the factory is very important and should be done carefully.

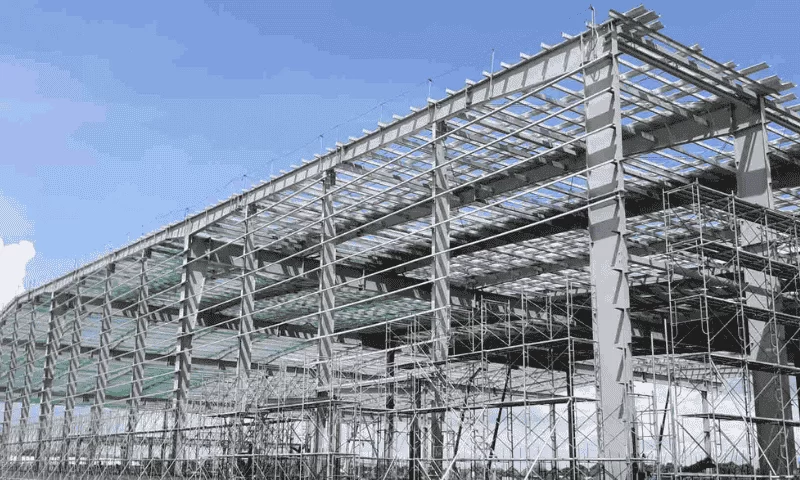

2. Structure of factory metal roofs

The roof sheet of the factory can be made up of many different materials such as steel, zinc, aluminum, etc. However, most commonly steel is thinly rolled then galvanized to increase durability. Corrugated iron roofing products have a lifespan of 30 to 50 years, much higher than that of plastic roofing (15 to 30 years). In addition, the corrugated iron roof is also capable of reflecting sunlight, helping to reduce high temperatures and cool more efficiently.

The factory and steel shed metal roof is composed of three main components: the frame system, the roof truss system, and the fastener system. These sections need to be designed and constructed correctly and safely to ensure the quality and longevity of the corrugated iron roof. Normally, these details are shown very clearly on the structural steel design so that this component fits into the overall steel structure in general.

- Frame system: This is the largest load-bearing part in the corrugated iron roof. The frame system is made of box iron and iron pipes, which are responsible for keeping the corrugated iron roof from being deformed when impacted or bent. When designing the frame, it is necessary to pay attention to the selection of materials to ensure that it is suitable to the area, scale and specific characteristics of each project.

- Truss – corrugated iron roof system: This is the upper part of the corrugated iron roof. The rafter system – corrugated iron roof is made of different types of corrugated iron roof, which is responsible for protecting the building from external factors. When designing and building a rafter system – it is necessary to select the proper type of corrugated iron roof suitable to the area, scale and specific characteristics of each project.

- Fastener system: This is the part that connects other parts of the corrugated iron roof. The screw system should be selected in chrome-plated stainless steel for optimal hardness and proper corrosion resistance. The rubber gasket system must also be sealed to prevent rainwater from seeping inside. Additionally, glue can be used to increase the durability of the entire system.

See more: Structural Steel: Types, Properties, And Applications 2025

3. The 6 most commonly used types of factory metal roofs

Currently, there are many types of factory metal roofs on the market. Here are 6 types of corrugated iron roofs most commonly used in factory buildings:

- 5-wave corrugated iron:

5 wave corrugated iron is a type of corrugated iron with 5 parallel U- or V-shaped wave lines running along the corrugated board structure. This type of corrugated iron has a high bearing capacity and is not deformed when impacted or bent. 5-wave corrugated iron also has ample sound and heat insulation properties, promoting noise reduction when it rains.

- 7-wave corrugated iron:

7-wave corrugated iron is a type of corrugated iron with 7 wave lines running along the corrugated board. A special feature of 7-wave corrugated iron is its deep and symmetrical U-wave structure. 7 wave corrugated iron has efficient bearing capacity and waterproofing, suitable for large-area projects. Moreover, this type of corrugated iron also has many colors and designs to choose from, bringing diversity and richness to the project.

- 9-wave corrugated iron:

9-wave corrugated iron is a type of corrugated iron with 9 wave lines running along the sheet, deep and symmetrical U-wave structure. 9-wave corrugated iron has good bearing capacity and waterproofing, suitable for large-area projects. 9-wave corrugated iron also has many colors and designs to choose from, creating diversity and richness for the project.

See more: Five Main Applications Of Metal Buildings

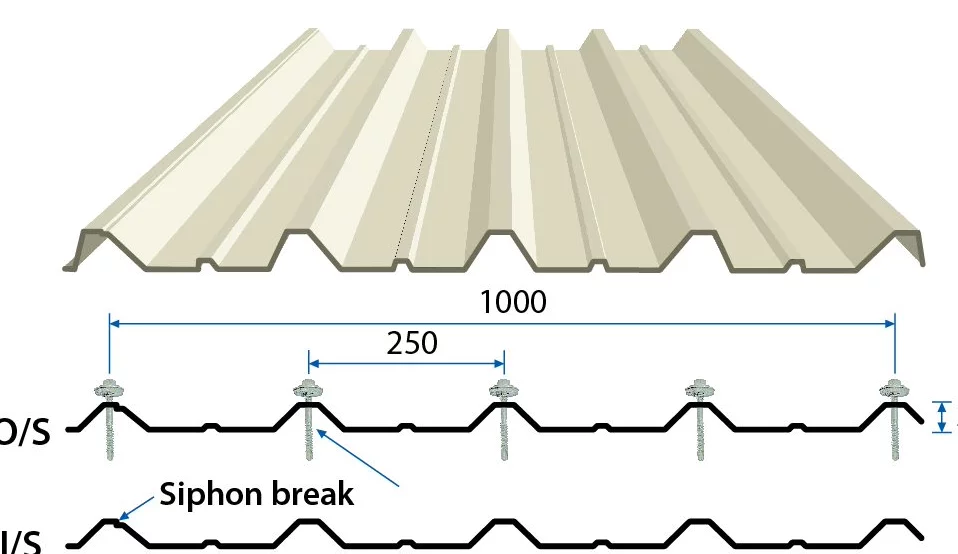

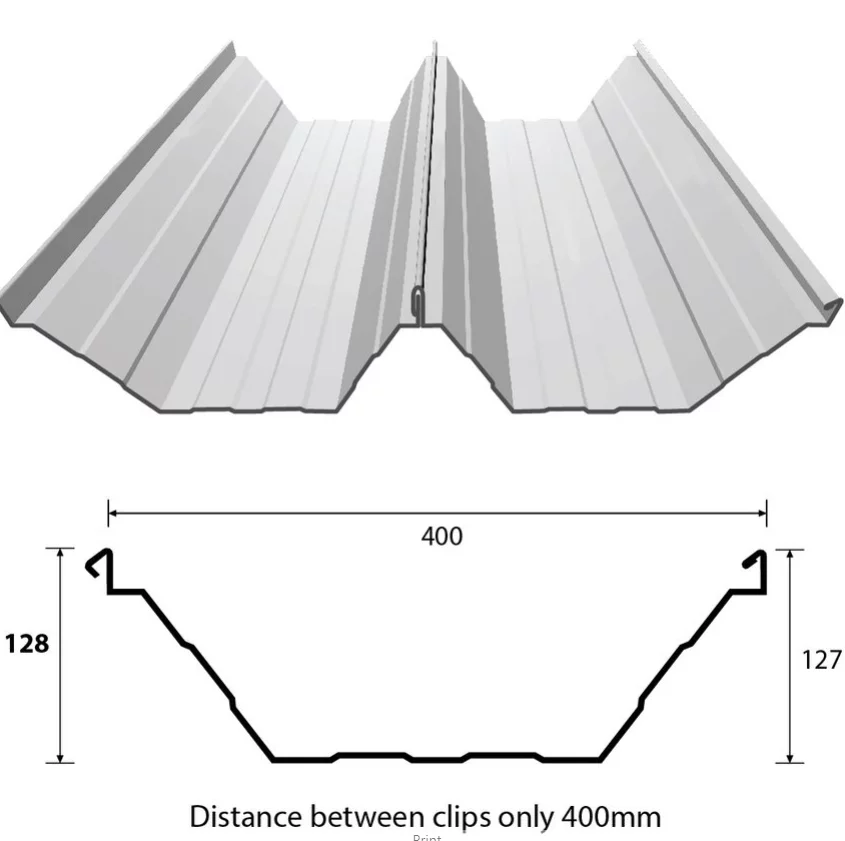

- Cliplock corrugated iron:

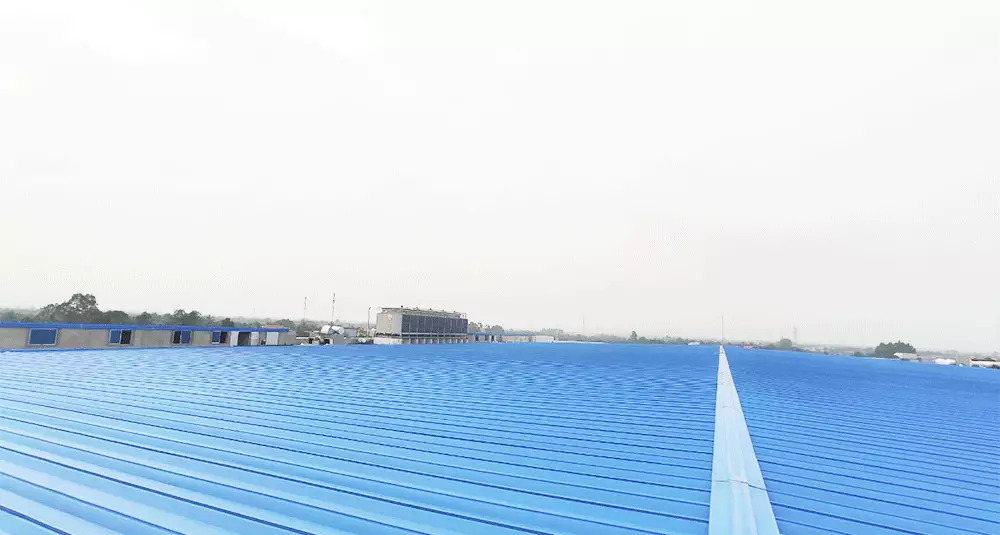

Cliplock corrugated iron is a type of corrugated iron commonly used in factories and warehouse constructions. The outstanding feature of Cliplock corrugated iron is its convenient and quick connection system between corrugated iron sheets. Instead of using accessories such as traditional corrugated iron clamps, Cliplock corrugated iron has specially designed pre-connected edges, allowing corrugated iron sheets to be stacked together easily. Featuring excellent waterproofing and bearing capacity, Cliplock corrugated iron also ensures the stability and sustainability of the corrugated iron roof. However, this type of corrugated iron roof has the highest cost compared to other types of corrugated iron.

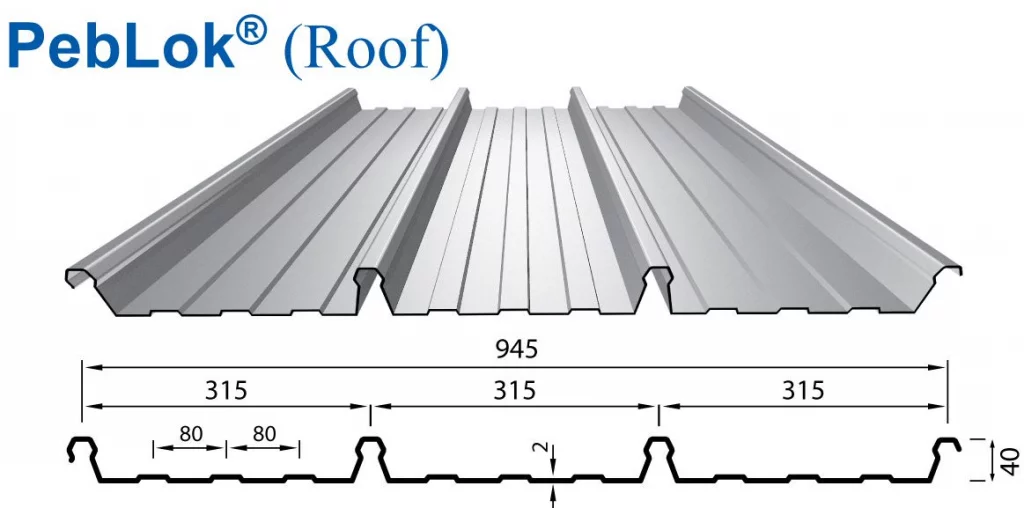

- Lockseam corrugated iron:

Lockseam corrugated iron is a type of high-quality corrugated iron commonly used in architectural and industrial works. The outstanding feature of Lockseam corrugated iron is the special mechanical connection system, which allows the corrugated iron sheets to be fastened together accurately and safely. Featuring superb bearing capacity and high waterproofing, Lockseam corrugated iron is widely used in buildings such as factories, commercial centers, hotels and other industrial buildings.

- Polycarbonate Corrugated Sheet

This is a type of corrugated roof made from transparent plastic or glass, allowing natural light to shine into the factory therefore saving on electricity costs. Light corrugated iron is often combined with other types of corrugated iron to create the highest efficiency. However, this type of corrugated iron roof needs regular maintenance to avoid dust or scratches.

4. Why is a metal factory roof so popular?

Factory roofing is an economical and effective solution for industrial projects. There are many reasons why corrugated metal roofs are popular:

- The corrugated iron roof of the factory has excellent bearing capacity and waterproofing, helping to protect the building from the effects of weather and the environment.

- The corrugated iron roof of the factory has superb sound and heat insulation properties, helping to reduce noise and temperature in the factory and creating a comfortable and safe working space for employees.

- The corrugated iron roof of the factory has many colors and designs to choose from, helping to increase the aesthetics and style of the building.

- The corrugated iron roof for the factory has a reasonable price and a long life, promoting savings on investment and maintenance costs.

5. Advantages of using Peb Steel’s factory roof

Pebsteel roof corrugated iron is the optimal choice for pre-engineered steel buildings, meeting all of the requirements for durability, aesthetics and economic efficiency. With outstanding quality and professionalism in production, Pebsteel roof sheets bring reliability and class to construction projects.

Pebsteel’s factory roof sheets have many outstanding advantages such as:

- They are manufactured according to international standards, with high quality and durability. Pebsteel factory roofing sheets are rust-proof, anti-corrosion, fireproof, chemical-resistant, bacteria-resistant, and mildew-resistant.

- Feature superb sound and heat insulation, which helps reduce noise and temperature in the factory.

- The ability to effectively cool the roof of the workshop, saving on electricity costs due to the ability to reduce the temperature in the factory from 5 to 10 degrees Celsius without the need to install cooling devices.

Customers can refer to Pebsteel roofing products such as LokSeam®, PebWall®, PebSeam128®, etc. for their projects.

6. Conclusion

Residential corrugated iron roofs are a fuel-efficient and effective solution for industrial processes. We hope this article was useful for our customers looking for the right type of roofing for their projects. Please contact Pebsteel via email at marketing@pebsteel.com.vn or phone number +84 908 883531 for more information about our prefabricated home building products and services.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.