The global architectural and engineering landscape is witnessing a paradigm shift. As industries evolve and urbanisation accelerates, the demand for construction methodologies that offer speed, precision, and sustainability has reached unprecedented levels. Traditional reliance on reinforced concrete, although still relevant, is being increasingly challenged by the superior adaptability of steel. In this context, customised steel solutions play a vital role in industrial, construction, and commercial projects. They meet the specific requirements of each project, optimise costs, and enhance overall efficiency.

Partnering with a top-tier Steel Company like Pebsteel, a leader in steel structure fabrication in Vietnam, represents more than just a procurement decision; it is a strategic alliance that defines the long-term operational success of an enterprise. This comprehensive guide explores the multifaceted benefits of steel structures, diving deep into technical specifications, sector-specific applications, and the rigorous criteria for selecting the right partner in a competitive market.

1. The Role and Capabilities of a Premier Steel Company

To understand the value of a steel structure, one must first understand the entity behind its creation. Unlike companies that only supply steel components, a premier Steel Company operates as an integrated ecosystem, managing the entire lifecycle of a building from conceptual design to final erection.

Leading steel companies provide professional fabrication, supply, and installation services. They utilise modern technology, maintain high-quality standards, and have strong market reputations. Companies such as Pebsteel have pioneered this integrated approach. By controlling every stage of the supply chain, they mitigate risks associated with miscommunication, delay, and quality inconsistency.

A premier Steel Company will deliver seamless, end-to-end steel building solutions

Advanced Engineering and Design

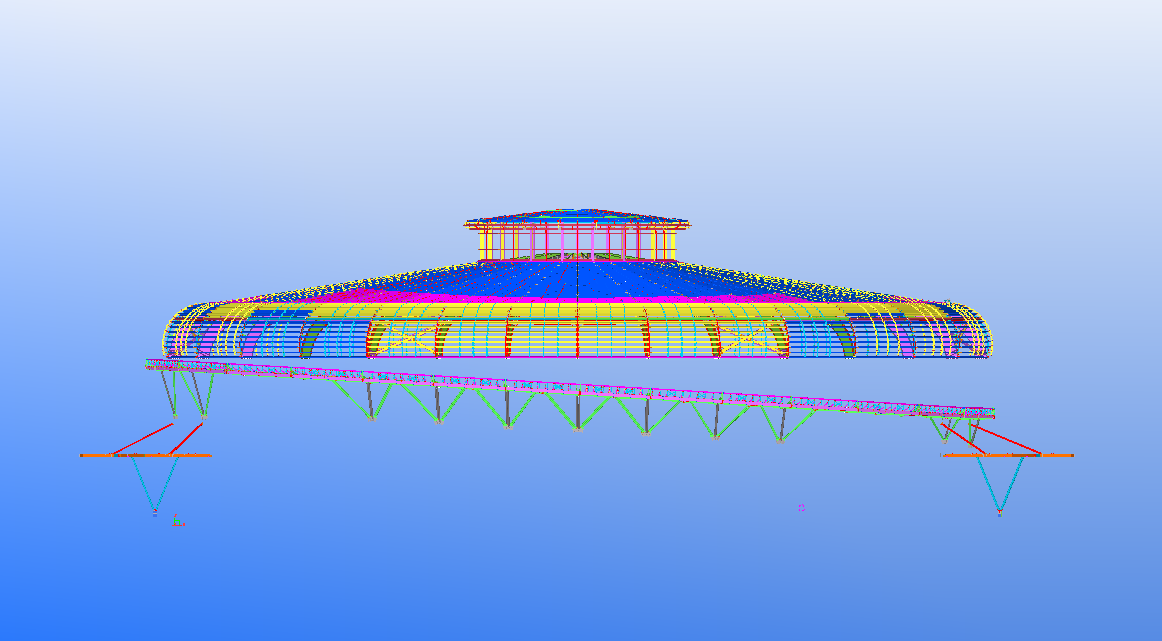

The process begins with advanced engineering. Utilising cutting-edge software like Tekla Structures, SAP2000, and proprietary BIM (Building Information Modelling) tools, engineers can simulate wind loads, seismic activities, and thermal expansion before a single piece of steel is cut. This digital twin technology ensures that the steel building is optimised for both safety and material usage.

Precision Fabrication

In the manufacturing phase, automated CNC (Computer Numerical Control) machines ensure that steel plates are cut, drilled, and welded with millimetre-level precision. This reduces human error and guarantees that components fit together seamlessly on-site.

2. The Technical Superiority of Customised Steel Solutions

A common misconception in construction is that pre-engineered steel buildings are rigid, “cookie-cutter” structures. In fact, modern pre-fabricated steel components are designed to be adaptable. These components are manufactured in standardised modules but can be precisely tailored in size, configuration, and steel grade to meet the specific requirements of each project. This approach not only optimises costs and accelerates construction but also ensures long-term durability and flexibility for a wide range of building applications.

2.1. Structural Flexibility and Clear Span Design

A key technical advantage of working with a specialised Steel Company is the ability to achieve clear-span designs. Traditional concrete columns often obstruct internal space, limiting the layout of machinery or storage racks. Steel frames, however, can span up to 100 meters or more without intermediate columns. This architectural freedom allows businesses to maximise their usable floor area (UFA).

2.2. Material Grades and Specifications

Customisation also extends to the selection and composition of the steel itself. Depending on the environmental conditions—whether the project is a corrosive chemical plant or a humid coastal resort—the type of steel can be carefully chosen. High-tensile steel plates, such as Grade Fifty or its equivalent, are often used to reduce the overall weight of the structure while maintaining its full load-bearing capacity. In addition, protective coatings, including hot-dip galvanisation or specially formulated aesthetic paints, are applied to enhance both the longevity and visual appeal of the building.

A steel company will supply pre-engineered steel materials, ensuring project flexibility and efficiency

3. Transforming the Industrial Sector

The industrial sector remains the backbone of the steel construction market. From heavy manufacturing to logistics, the requirements for durability and operational flow are non-negotiable. Industrial projects, such as factories, production facilities, and warehouses, utilise customised steel solutions to enhance productivity and optimise space. These solutions also allow for easy expansion and long-term maintenance.

3.1. Optimizing Factory Operations

In a manufacturing context, the structural steel design must support not only the building envelope but also internal systems such as overhead cranes, monorails, and heavy HVAC units. Pebsteel engineers these dynamic loads into the primary frame, ensuring that the building actively supports the production process rather than just housing it.

3.2. Warehousing and Logistics

For logistics centres, vertical space is as valuable as horizontal space. Steel buildings enable significant eave heights, allowing for high-rack storage systems. Additionally, the modular nature of steel frames means that if a business needs to double its storage capacity, the Steel Company can easily extend the structure by adding new bays to the existing end-wall, a process that is far more complex and costly with concrete.

The steel company also provides pre-engineered steel building construction with guaranteed quality

Read Article: Customized Pre Manufactured Steel Buildings for Industrial & Commercial Use

4. Elevating Commercial Aesthetics and Functionality

While industrial applications of steel are well-known, its use in the commercial realm is rapidly expanding. Developers are increasingly recognising that steel offers a unique blend of modern aesthetics and fast return on investment. In commercial projects, customised steel solutions are ideal for shopping centres, offices, showrooms, and hotels. Benefits include high aesthetics, space optimisation, and cost-effective construction.

4.1. Architectural Freedom

Modern commercial buildings require distinct identities. The ductility of steel allows architects to create curves, cantilevers, and complex geometric forms that capture consumer attention. A car showroom, for instance, requires vast glass facades to display vehicles; a steel frame provides the necessary skeletal strength with minimal visual obstruction, creating a “floating” effect that enhances the customer experience.

4.2. Speed to Market

In the commercial sector, time is money. A hotel or shopping mall that opens six months early generates six months of additional revenue. The speed of erecting a steel building—often 30% to 50% faster than concrete alternatives—makes it the preferred choice for developers focusing on rapid capital turnover.

A project handed over to a customer by Pebsteel, the steel company, was operated very smoothly and efficiently

5. Critical Factors in Partner Selection

Given the complexities involved in large-scale construction, selecting the right partner is a decision fraught with risk. It requires thorough due diligence. When selecting a steel company, businesses should evaluate experience, completed projects, and reputation. Production technology, quality standards, after-sales service, and design consultation are also crucial factors.

5.1. Evaluating Experience and Portfolio

A portfolio is a testament to competence. A reliable Steel Company should be able to showcase a diverse range of completed projects, from simple warehouses to complex multi-story commercial hubs. Pebsteel, for example, has a vast portfolio spanning multiple countries, demonstrating its ability to adapt to different building codes, climates, and cultural preferences.

5.2. Quality Standards and Certifications

Certifications are the benchmarks of trust. Investors should verify if the company adheres to international standards such as:

- AWS (American Welding Society) for welding quality.

- AISC (American Institute of Steel Construction) for fabrication processes.

- ISO 9001 for quality management systems.

Adherence to these standards ensures that the structure will perform safely under stress, protecting both human life and assets.

5.3. After-Sales Service

The relationship with a Steel Company should not end when the last bolt is tightened. A comprehensive warranty and responsive after-sales service are essential. This includes periodic maintenance checks, leak repairs, and consultation for future modifications.

Key criteria for choosing a trusted steel company for safe, efficient, and long-lasting projects

6. Optimizing Investment: A Comparative Analysis of Economic Efficiency

In the competitive realm of industrial and commercial development, the initial price tag is rarely the sole determinant of value. Instead, astute investors prioritise the Total Cost of Ownership (TCO), evaluating the project’s financial impact over its entire lifecycle. This is where modern engineering demonstrates its superior viability. Customised steel solutions save costs compared to traditional materials and shorten construction timelines due to pre-fabricated components and quick assembly. This dual advantage of financial and temporal savings creates a compelling case for choosing steel over conventional reinforced concrete.

6.1. A Breakdown of Direct Cost Savings

The economic superiority of a steel building is not merely theoretical; it stems from tangible reductions in specific construction phases. When analysing the budget, three key areas stand out:

- Foundation Cost Reduction: Steel possesses an exceptional strength-to-weight ratio, making the resulting structure significantly lighter than a concrete equivalent. This reduced dead load allows engineers to design smaller, shallower, and less expensive foundations. In regions with poor soil conditions where deep piling would typically be expensive, this saving can be substantial.

- Labour Optimisation: Traditional construction relies heavily on prolonged, labour-intensive on-site fabrication. In contrast, the steel process shifts the workload to the factory. On-site labour is restricted to assembly rather than creation, requiring fewer workers and fewer man-hours, which directly lowers overall labour expenses.

- Waste Minimisation: Precision engineering ensures that every beam and column is cut to exact specifications before arriving at the site. This process generates virtually no construction waste, in stark contrast to the significant debris and disposal costs associated with timber formwork or concrete pouring.

6.2. Time as a Strategic Investment

Beyond direct material costs, time acts as a critical currency in construction finance. The “pre-engineered” methodology enables a highly efficient parallel workflow: the steel structure is manufactured in a controlled factory environment, simultaneously with the site being graded and foundations being poured.

This concurrent activity compresses the project timeline by 30% to 50% compared to sequential traditional methods. For a business, this shortened timeline translates into tangible financial benefits, including reduced interest payments on construction loans and, most importantly, faster operational readiness to begin generating revenue.

7. Sustainability and Environmental Impact

In an era where Corporate Social Responsibility (CSR) and Green Building standards (such as LEED or LOTUS) are prioritised, steel is the material of choice. Steel is the most recycled material on the planet. A steel building supplied by a responsible steel company, such as Pebsteel, is often made from a high percentage of recycled content and is 100% recyclable at the end of its lifecycle.

Furthermore, the precision of pre-engineered buildings ensures excellent airtightness. When combined with modern insulation materials (such as PU foam or glass wool), these buildings offer superior thermal efficiency, reducing the energy required for heating and cooling. This lowers the operational carbon footprint of the facility for decades to come.

The decision to invest in a facility is a crucial decision that affects the future of a business. It requires a forward-thinking approach that balances immediate costs with long-term value. Partnering with a leading steel company offers long-term benefits, including tailored solutions, increased efficiency, cost savings, and time efficiency. It is key to building sustainable and long-lasting projects.

By choosing a partner like Pebsteel, investors are not just buying a structure; they are acquiring a legacy of engineering excellence. Whether the goal is to dominate the industrial manufacturing sector or to create an iconic commercial landmark, customised steel solutions provide the strength, flexibility, and speed necessary to succeed in a competitive world. The future of construction is undeniably efficient, sustainable, and built on steel.

Do you require a comprehensive, high-performance solution for your next steel building construction project? Pebsteel’s highly experienced engineers are ready to consult with you.

Contact us today to discuss your project specifications and receive expert consultation. Please note that the information provided is for reference purposes only:

- Email: marketing@pebsteel.com.vn

- Phone: (+84) 908 883 531

This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.