Assembling steel structures is a crucial part of the construction industry, playing a key role in creating a solid framework for buildings ranging from factories and warehouses to office buildings and skyscrapers. This process requires meticulousness, precision, and strict adherence to technical procedures to ensure the durability, safety, and efficiency of the structure.

This article will provide you with an overview of the steel structure erection process, including the main steps, important considerations, and factors affecting construction quality. As a result, you can better understand the importance of choosing a reputable contractor and closely supervising the construction to ensure the safety of the structure and achieve optimal investment efficiency.

Overview of the Steel Structure Assembly and Construction Process

The process of assembling and constructing steel structures is one of the most important stages in building modern structures. Steel structures are preferred due to their flexibility, high durability, and good load-bearing capacity. This process includes many complex steps, from initial design to final installation and finishing.

First, engineers must conduct geological surveys and detailed designs. Then, steel components are manufactured at the factory according to exact technical specifications. The on-site assembly process begins with foundation preparation, followed by erecting the main columns, beams, and supporting structures.

Throughout this process, labour safety is always the top priority. Workers must be thoroughly trained and equipped with adequate protective equipment. The use of modern lifting equipment such as cranes and forklifts also plays an important role in moving and installing heavy components.

The steel structure assembly process requires close coordination between different teams, from design engineers and project managers to construction workers. Each step in the process needs to be carried out with high accuracy to ensure the stability and safety of the structure after completion.

Important Cautions When Assembling and Constructing Steel Structures

Cautions Before Assembling and Constructing Steel Structures

Before beginning the process of assembling and constructing steel structures, many important factors need to be carefully considered to ensure the project’s success.

2.1 Preparing Personal Protective Equipment

To ensure the safety of those carrying out the construction, protective equipment must be prepared throughout the construction process to limit potential work accidents:

- High visibility protective clothing

- Sturdy safety helmets, safety harnesses

- Protective gloves

- Safety goggles, equipment bags

- Life lines

In particular, when workers are working at high areas, it is mandatory to equip them with the following high-rise construction safety equipment:

- Scaffolding

- Construction safety nets

- Fall protection nets

2.2 Paying Attention to Weather

Erecting steel structures for outdoor constructions like factories and plants requires studying and considering weather factors through weather forecasts to avoid issues that could hinder the construction process.

Heavy rain and humidity can make the construction site slippery, endangering workers at heights, while strong winds can affect the operation of construction equipment like cranes and tower cranes.

By paying attention to weather factors before constructing steel structures, contractors can ensure worker safety, protect assets, improve construction quality, and maintain project schedules. This contributes significantly to building sustainable, safe, and efficient structures.

2.3 Checking Equipment, Materials, Tools, and Transportation

Inspecting equipment, materials, tools, or means of transportation before use, assembly, and construction is an extremely important step. Steel needs to be thoroughly inspected according to quality standards and certificates of origin. In particular, structural bolts and anchor bolts are used to connect important components of the structure in steel-framed buildings.

2.4 Examining the Construction Space

The construction space also needs to be thoroughly inspected, and site preparation should be done carefully. The construction site must be levelled and ensure sufficient stability to bear the weight of the steel structure and construction equipment. The foundation needs to be designed and built to suit the load of the structure.

Cautions During Assembly and Construction of Steel Structures

During the process of assembling and constructing steel structures, many factors need special attention to ensure the quality and safety of the project.

3.1 Steel Structure Design

Steel structure design is the first and the most important step in the construction process. It requires accuracy and careful calculation to ensure the stability and safety of the structure. Design engineers need to consider many factors such as load, environmental conditions, and the intended use of the structure.

During the design process, choosing the appropriate type of steel is crucial. Strength, load-bearing capacity, and cost need to be balanced. Additionally, the design must consider future expansion possibilities and the flexibility of the structure.

Using modern design software such as AutoCAD can help create detailed 3D models, helping to detect and resolve potential issues before construction begins. This not only saves time and cost but also ensures high accuracy during the installation process.

Cautions During Assembly and Construction of Steel Structures

3.2 Supervision of Steel Structure Installation

Supervising the installation of steel structures is an essential part of ensuring that the project is carried out according to design and meets safety standards. Supervisors need experience and in-depth knowledge of steel structures to detect and promptly address any arising issues.

Effective supervision requires diligent adherence to proper installation protocols, which include precise placement of components and meticulous execution of joints and connections. Equally critical is the routine inspection of lifting equipment and verification of its proper usage as a fundamental aspect of supervisory responsibilities.

3.3 Notes on Moving Up and Down the Steel Structure Construction Site

Safety when moving around a steel structure construction site is extremely important. Construction sites often have many dangerous areas, and improper movement can lead to serious accidents.

First, all staff and workers must be fully equipped with personal protective equipment such as helmets, safety shoes, and safety harnesses when working at heights. Safe and clear pathways need to be established on site, avoiding areas with risks of falling materials or equipment.

When moving to high places, safe means such as construction elevators or securely installed temporary stairs should be used. Climbing directly on steel structures is absolutely prohibited. For high-work areas, protective railings and safety nets need to be installed.

In addition, regular safety training and reminders should be organised for all staff on site. This helps raise awareness and emergency handling skills for everyone.

3.4 Checking Scaffolding Locks, Column Systems, Beams and Trusses

For scaffolding, the stability and firmness of the connectors need to be checked. Ensure that scaffolding is installed on a solid foundation and can bear the necessary load.

Check the support bars and braces for any bending or damage.

For the column system, which is an important foundation, careful inspection is needed. Use accurate measuring devices to ensure columns are installed in the correct position according to the design.

For beams and trusses, carefully check the joints, especially welds and bolt connections. Ensure they are executed with proper technique and meet strength requirements. These checks should be performed periodically and after each important installation phase.

If any issues are detected, they should be addressed immediately to ensure the safety and progress of the project.

3.5 Checking Bolt Tightening Force in the Structure

Checking bolt tightening force is an important step in the steel structure installation process, ensuring the stability and safety of the structure. Bolts that are not tightened enough can lead to looseness in the structure, while overtightening can cause unwanted stress or even damage the bolts.

Bolt tightening force checks need to be performed with specialised tools. Strict adherence to standards and regulations on tightening force for each type and size of bolt is necessary.

The checking process should follow a standard procedure, starting with marking the initial position of the nut, then tightening and checking the force. Note that the tightening force may change over time due to material expansion and contraction, so periodic checks are necessary.

Additionally, attention should be paid to environmental conditions such as temperature and humidity, as they can affect the tightening force. In case bolts are found not meeting the tightening force requirements, immediate adjustment or replacement is necessary.

3.6 Checking the Alignment of Main Structures in Steel Frame Workshops

Checking the alignment of main structures in steel frame workshops is a crucial step to ensure the accuracy and stability of the entire structure. Inaccurate alignment can lead to imbalance, affecting the load-bearing capacity and lifespan of the structure.

4. Cautions After Assembly and Construction of Steel Structures

After completing the assembly and construction process of steel structures, there are still many important tasks to be carried out to ensure the quality and long-term durability of the structure.

4.1 Project Acceptance

This stage focuses on inspecting the scaffolding system and construction process to ensure labour safety. Technical experts will conduct thorough checks of the entire scaffolding system, ensuring they are securely installed and comply with safety standards. They will examine the stability of the scaffolding, check connection points, and ensure all parts are in good working condition.

4.2 Acceptance of the Completed Construction Phase

In this stage, the structure will be inspected on-site. Experts will conduct detailed inspections of each part of the steel structure, ensuring that everything is installed correctly according to the design drawings and meets the required technical standards. They will check welds, bolt tightness, column verticality, and beam flatness.

4.3 Final Acceptance and Completion

This is the final stage of the acceptance process. In this stage, the entire completed area of the structure will be meticulously inspected. Experts will evaluate the overall structure, including the smallest details such as protective paint coatings, finishing details, and overall aesthetics. All detailed information about the structure will be recorded in the handover report with detailed information before putting it into use.

Caution After Assembly and Construction of Steel Structures

5. Important Considerations for Construction Workers

To ensure the safety of construction workers, many important factors need attention. First, providing adequate personal protective equipment is essential. Each worker should be supplied with a helmet, safety goggles, gloves, safety shoes, and safety harness to protect them from potential accidents and injuries during work.

Additionally, placing clear and proper safety signs and instructions is crucial. These signs help inform about specific risks and necessary precautions. At the same time, construction workers also need to be thoroughly trained on safety regulations and familiarised with safety techniques appropriate for each specific type of work they undertake.

For buildings from the second floor up, preparing and maintaining safety nets throughout the work process is indispensable. When erecting with cranes, handles should be attached to both ends of the steel frame to enhance safety. Moreover, maintaining a safe distance of at least 5 metres is also an important measure to ensure the safety of construction workers during the work process.

Important Cautions When Assembling and Constructing Steel Structures

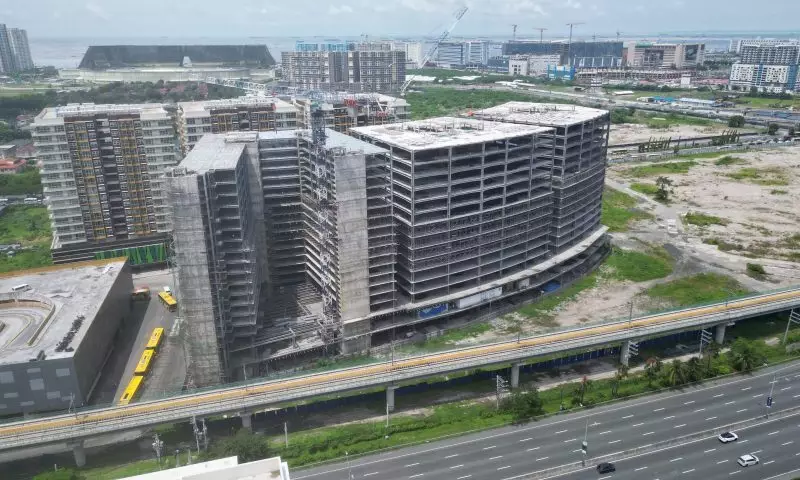

The process of assembling and constructing steel structures requires high attention to every detail, from initial design to final acceptance. With in-depth experience in this field, Pebsteel has demonstrated superior ability in meeting these stringent requirements. By applying advanced technology and focusing on every detail, Pebsteel ensures that each steel structure is not only aesthetically pleasing but also safe, durable, and meets all stringent standards of modern construction.

Here, you will find detailed information, real-world projects, and in-depth advice from a team of experienced engineers. Or contact Pebsteel via email at [email protected] or phone number: (+84) 908 883 531 for immediate consultation!