In the competitive landscape of modern construction, efficiency and endurance are essential. The evolution of global infrastructure calls for materials that deliver speed, strength, and adaptability. At the heart of every successful commercial and industrial project is a well-engineered steel structure design. This specialised field ensures that a building not only fulfils its functional requirements but also meets high standards of safety and cost-effectiveness.

Pebsteel recognises that steel structure design is a key factor in industrial and commercial developments. It forms the foundation for optimised costs, enhanced building durability, and the timely completion of construction projects.To provide a clearer understanding, this article outlines the core elements of professional steel structure design and explains how they are implemented in practice.

1. What Defines Professional Steel Structure Design?

Steel structure design is a systematic and meticulous process that goes far beyond simple drafting. It is the sophisticated engineering discipline of creating technical drawings and structural simulations to ensure safety, sustainability, and efficiency. Utilising the exceptional strength-to-weight ratio of structural steel, designers maximise interior flexibility and long-span capabilities.

The professional process includes:

- Site Survey and Analysis: Assessing local conditions, seismic, and environmental loads.

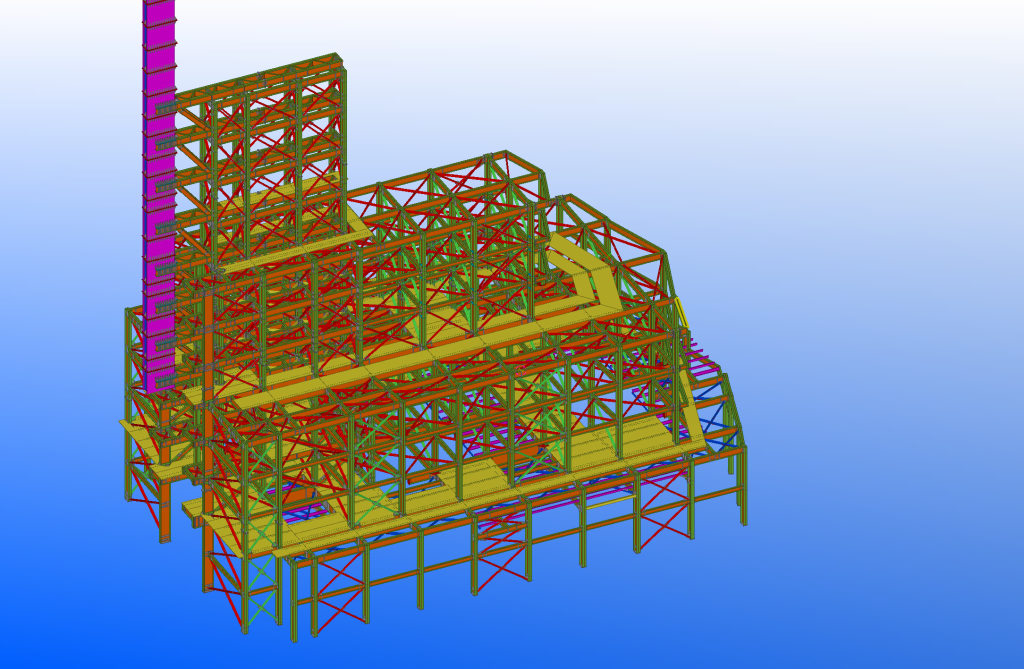

- Drafting and Modelling: Creating detailed blueprints and 3D models.

- Structural Simulation: Rigorous analysis using advanced codes (like AISC or Eurocode) to test load combinations and resistance.

- Final Approval: Ensuring strict adherence to regional safety codes and client specifications before fabrication.

Choosing the right partner is essential, especially a company with proven capabilities in both steel structure design and steel structure fabrication in Vietnam.

Moreover, it also ensures the necessary safety and delivers the desired aesthetic appeal for the project.

Professional steel structure design ensures safety, efficiency, and lasting performance

2. Core Principles of Effective Steel Structure Design

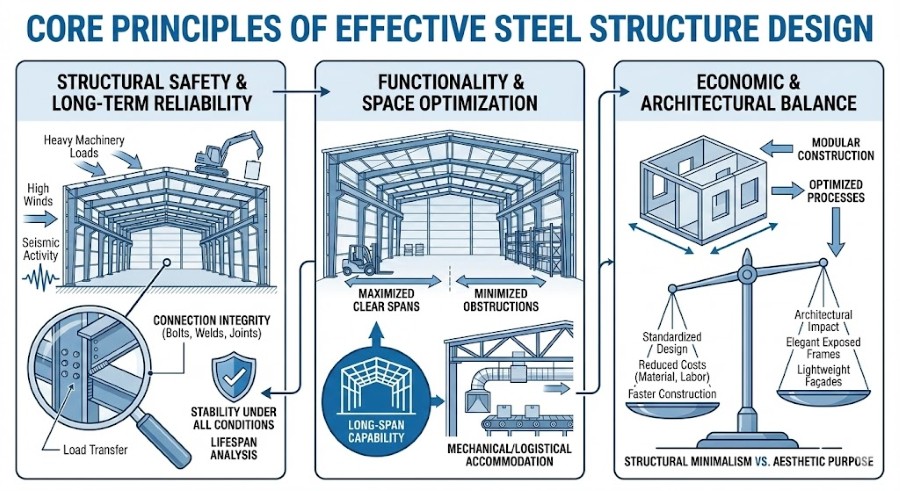

Achieving structural excellence requires adhering to fundamental engineering principles that govern safety, function, and economy.

2.1. Structural Safety and Long-Term Reliability

Every steel structure begins with one fundamental objective: safety. Whether it’s bearing the weight of heavy machinery in an industrial plant or resisting high winds and seismic activity, steel structure design must ensure stability under all plausible conditions. Achieving this requires accurate load assessments, reliable material properties, and a clear understanding of how different forces interact across the structure’s lifespan. The integrity of the connections (bolts, welds, and joints) is analysed to guarantee load transfer remains secure, preventing localised failures that could compromise the entire frame.

2.2. Functionality and Space Optimisation

A steel building is not just a skeleton; it’s a space intended for work, storage, assembly, or habitation. Good steel structure design enhances the usability of this space by maximising clear spans, minimising obstructions, and accommodating mechanical and logistical needs. Efficiency isn’t just a structural value, it’s also a spatial one. This is where the long-span capability of structural steel offers a substantial competitive edge.

2.3. Economic and Architectural Balance

Standardised steel structure design helps reduce material and labour costs and saves construction time through detailed technical drawings and optimised processes. Steel is inherently cost-effective when properly used, but true value lies in finding the balance between structural minimalism and architectural impact. Thoughtful design bridges engineering logic with aesthetic purpose, whether through elegant exposed frames, lightweight façades, or modular construction techniques.

Core principles of steel structure design ensure safety, functionality, and cost-effective efficiency (Source: Internet)

Read More: Customized Steel Solutions by a Leading Steel Company

3. Understanding Steel Structure Design: Loads and Regulatory Standards

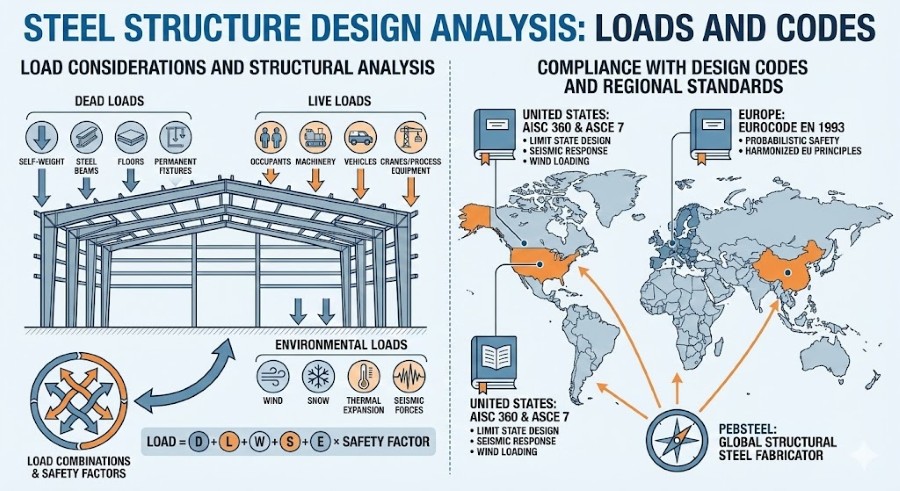

A successful steel structure design relies on rigorous calculation and adherence to codified standards.

3.1. Load Considerations and Structural Analysis

Steel structure design professionals must account for a variety of forces (or loads) that a building will encounter during its service life:

- Dead Loads: The self-weight of structural components, including steel beams, floors, and permanent fixtures.

- Live Loads: Variable loads from occupants, machinery, vehicles, and stored goods. In industrial steel buildings, live loads from cranes or process equipment can be immense.

- Environmental Loads: Wind, snow, thermal expansion, and seismic forces, which vary based on geographic location and local code requirements.

Design codes do not evaluate these loads individually. Instead, they specify particular load combinations, integrating multiple force scenarios simultaneously, such as heavy rain combined with strong wind gusts. Safety factors are incorporated to address uncertainties, ensuring the structure remains secure even under rare or extreme conditions.

3.2. Compliance with Design Codes and Regional Standards

Steel structure design is governed by technical codes that ensure safety and consistency. International projects require an understanding of major standards:

- United States: AISC 360 and ASCE 7 guide limit state design, seismic response, and wind loading.

- Europe: Eurocode EN 1993 emphasises probabilistic safety and harmonised EU design principles.

- China: GB 50017 integrates structural, seismic, and environmental factors tailored to diverse regional climates.

Pebsteel’s expert engineering teams must reconcile these standards to meet both legal requirements and engineering best practices, especially when serving as a global structural steel fabricator.

Steel structure design analysis ensures safety by accurately assessing loads and complying with codes (Source: Internet)

4. How Steel Structures Design Serve Industrial and Commercial Projects

The robust nature and adaptability of structural steel make it an ideal material for a diverse array of projects.

4.1. Steel Structure Design in Industrial & Logistics Steel Buildings

Steel structure design is widely used in factories, production facilities, and logistics warehouses. These environments demand vast, unobstructed areas. Steel excels here as it optimises space, supports heavy machinery, increases productivity, and helps meet specific technical requirements.

The use of a prefabricated steel building system further enhances this sector by allowing for rapid assembly, minimising site work, and delivering projects on time, a key competitive advantage for any structural steel fabricator. This fast-track construction method is crucial for reducing downtime and accelerating the client’s operational readiness.

4.2. Steel Structure Design for High-Aesthetics Commercial Projects

In commercial projects, steel structures are suitable for shopping centres, offices, showrooms, and hotels. Unlike traditional materials, steel allows for high degrees of architectural expression. Key benefits include high aesthetics, optimised space (fewer load-bearing walls), and effective support for business operations through flexible interior layouts. Steel building technology offers modern, sleek designs that become lasting architectural landmarks.

A construction project according to pre-engineered steel structure design to ensure quality and progress as proposed

5. Steel Structure Design for Strength, Safety, and Sustainability

Long-term performance is achieved through proactive design choices regarding stability and environmental protection.

5.1. Stability, Bracing, and Lateral Resistance

Buildings must resist lateral forces such as wind and seismic activity, which can cause sway, drift, or even collapse. Bracing systems, whether diagonal, rigid, or moment-resisting, anchor the frame and maintain structural stability. Designers also consider how these systems impact usability, aesthetics, and the integration of building services, such as HVAC and fire protection.

5.2. Fire and Corrosion Protection in Steel Structure Design

Though non-combustible, structural steel loses strength rapidly above 500°C. Likewise, unprotected steel exposed to moisture or chemicals will corrode, compromising its load-bearing capacity.

To mitigate these risks, steel structure design incorporates protection strategies:

- Fire Protection: Steel elements are coated with intumescent paints, fireproofing boards, or encased in concrete to delay temperature rise.

- Corrosion Protection: Galvanisation, epoxy coatings, and stainless steel selections are specified, tailored to the building’s environment and usage profile (especially important for coastal or chemical facilities).

5.3. Material Selection and Sustainability

One of steel’s greatest advantages is its high strength-to-weight ratio, which reduces structural mass. Furthermore, steel is one of the world’s most recycled materials, making it a highly sustainable choice. Steel structure design contributes directly to green building initiatives by minimising waste and maximising the use of recycled content.

A project sticks close to steel structure design ensuring strength, safety, and sustainable building performance

6. Choosing the Ideal Steel Structure Design Provider

When investing in a major project, selecting a premium provider is critical. Pebsteel recommends a focused evaluation:

When selecting a steel structure design provider, consider experience, completed projects, design technology, and professional engineering teams.

- Engineering Depth: Does the team demonstrate expertise in global codes (AISC, Eurocode, GB) and complex load analysis?

- Technology & Quality: Are they utilising the latest software for simulation and adhering to standardised detailing practices?

- Support: Consultation, implementation support, and solution updates are also crucial for ensuring a smooth transition from design through construction.

By focusing on standardised processes, standardised steel structure design helps reduce material and labour costs and saves construction time through detailed technical drawings and optimised processes. This focus eliminates waste and ensures predictability throughout the project lifecycle.

Partnering with a trusted steel structure design provider offers long-term benefits: cost savings, safety, optimised timelines, and high-quality results. It’s not just about erecting a frame; it’s about crafting a resilient, economical, and sustainable asset.

Pebsteel provides integrated, expert steel structure design that translates architectural vision into structural reality. Our approach, rooted in rigorous analysis and deep industry experience, ensures your project is secure, efficient, and built to stand the test of time. It is key to the success and sustainability of projects.

Choosing the right steel structure design provider ensures expert and reliable results

7. Frequently Asked Questions (FAQs) on Steel Structure Design

7.1. What is the main advantage of steel in construction?

Structural steel offers an exceptional strength-to-weight ratio, enabling longer clear spans, lighter foundations, faster construction, and superior material recyclability, thereby promoting environmental sustainability.

7.2. What are the essential considerations for design?

Key requirements include accurate load calculations (dead, live, and environmental), structural stability (bracing/lateral resistance), compliance with regional design codes, and effective fire and corrosion protection strategies.

7.3. What is the role of a structural steel fabricator?

A structural steel fabricator is responsible for bringing the design drawings to life. They process the raw steel, cut, drill, assemble, and weld components into the final members ready for site erection.

7.4. What method is most widely used in steel structure design?

The Limit State Design (LSD) method is the dominant approach globally, accounting for both ultimate strength (collapse prevention) and serviceability (deflection and vibration limits) under various conditions. Steel structure design is the foundation that steel fabrication and pre-engineered steel building contractors rely on to ensure project quality. A well-detailed design helps keep construction on schedule, control costs within budget, and improve overall execution efficiency. This highlights the critical role of steel structure design and explains why choosing a reliable steel structure fabricator is essential for industrial and commercial projects.

Do you require a comprehensive, high-performance solution for your next steel building construction project? Pebsteel’s highly experienced engineers are ready to consult with you.

Contact us today to discuss your project specifications and receive expert consultation:

- Email: marketing@pebsteel.com.vn

- Phone: (+84) 908 883 531

This content is for reference purposes only and does not constitute professional or contractual advice.