In today’s construction industry, steel structure building solutions are rapidly replacing traditional concrete thanks to their cost efficiency, fast installation, and high durability. A steel structure building is a carefully engineered system in which steel columns, beams, trusses, and supports work together to carry loads and provide rigidity.

These buildings are ideal for factories, warehouses, logistics centres, showrooms, offices, stadiums, and even aircraft hangars, meeting modern demands for speed and flexibility. This article explores their key benefits, common framing systems, and why they have become the preferred choice for forward-thinking investors.

1. Common Types of Steel Structure Buildings in Industrial Construction

To understand the benefits, it is essential first to recognise the versatility of the material. A steel structure building comprises various systems tailored to specific project requirements.

Portal Rigid Steel Frames

The Portal Rigid Frame is the backbone of most modern factories. They allow open spaces, maximise usable area, suit various types of projects, and can be easily expanded or modified in the future. This “clear span” architecture creates uninterrupted floor space, which is critical for production lines and storage.

Portal rigid steel frame used in modern steel structure buildings, providing a wide clear-span space for industrial operations.

Pre-Engineered Metal Buildings (PEMBs)

Pre-engineered metal buildings (PEMBs) represent a significant leap in technology. These are factory-fabricated steel building systems where components are cut, drilled, and welded off-site. Prominent international manufacturers, such as Pebsteel, utilise this pre-engineered approach to deliver projects that adhere to strict international engineering standards. Pre-fabricated components reduce labour and construction time, lower maintenance costs, and result in a lower overall lifecycle cost compared to traditional concrete structures.

Modern building utilising Pre-Engineered Metal Buildings (PEMBs)

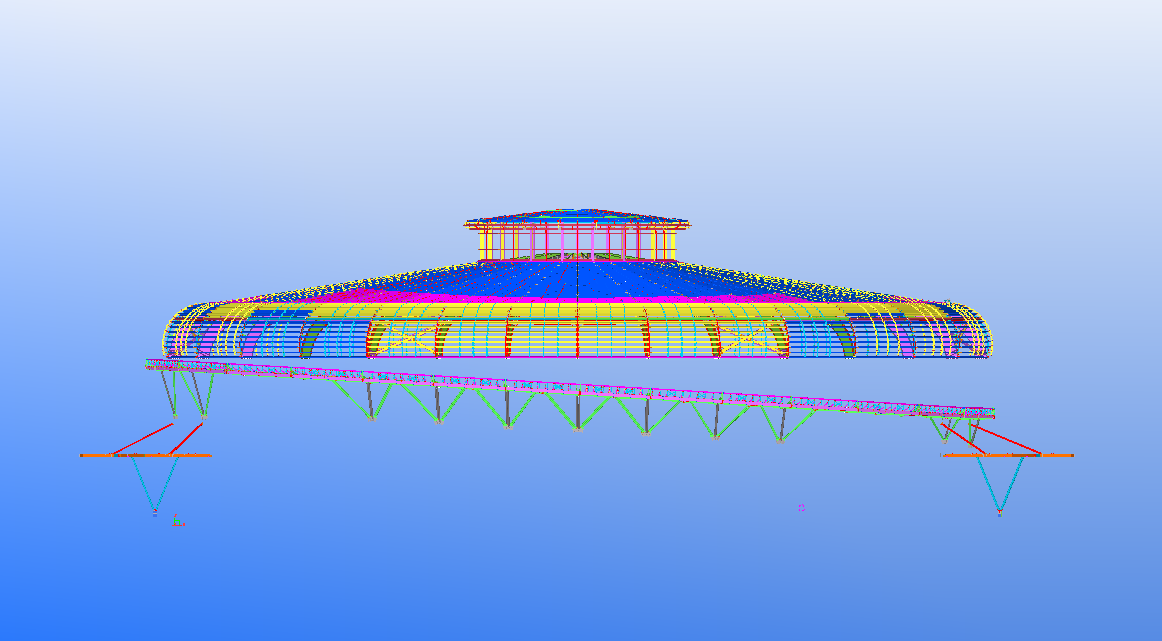

Specialised Steel Framing

From multi-storey frames for offices to complex trusses for stadiums, steel offers unmatched adaptability. For lighter applications, light-gauge framing provides a durable alternative to wood, while space frames offer three-dimensional load distribution for large terminals.

For Your Information: Steel Fabrication: A Complete Guide to Types, Processes, and Applications

2. Top 6 Key Benefits of Steel Structures for Industrial Buildings

Investing in a steel structure building is a strategic decision. Below are the primary benefits that drive the adoption of steel in industrial construction.

2.1. Cost Efficiency and Accelerated ROI

One of the most compelling arguments for steel is its economic value. While material costs fluctuate, the efficiency of the process drives savings.

- Prefabrication and quick assembly: Thanks to prefabrication,construction time is reduced by 30–50%, allowing the building to become operational sooner and accelerating the return on investment.

- Labour Savings: Because components are pre-made, on-site assembly is significantly faster and requires fewer labourers than casting concrete.

- Foundation Costs: Steel is lighter than concrete, reducing the size and cost of the required foundation.

- Lifecycle Value: When considering long-term operations, the reduced need for major repairs makes steel a financially sound choice.

2.2. High Strength and Exceptional Durability

Industrial buildings are subjected to heavy loads and environmental stress. Steel structures can bear heavy loads, resist harsh weather and earthquakes, and have a long lifespan of up to 50–70 years with proper maintenance.

- Load-Bearing: Whether utilising carbon or galvanised steel, the strength-to-weight ratio is superior to most materials.

- Resilience: High-quality steel buildings are designed to withstand extreme events, including hurricane-force winds and seismic activity, ensuring the safety of the assets housed within.

Steel structure building designed for high strength and long-term durability in industrial environments.

2.3. Flexibility and Customisation

Adaptability is crucial in a dynamic market. A steel building offers the flexibility that rigid materials cannot. They allow open spaces, maximise usable area, and make it easier for businesses to grow in the future.

- Easy Expansion: New bays can be added to an existing structure with minimal disruption.

- Custom Design: Engineers can customise frame designs to accommodate specific machinery layouts.Leading companies like Pebsteel often customise pre-engineered designs to meet unique project requirements while ensuring structural safety.

2.4. Sustainability and Environmental Impact

In an era where Green Building standards are becoming mandatory, steel is a frontrunner. Steel is 100% recyclable, generates minimal material waste, reduces environmental impact, and aligns with modern green building standards.

- Circular Economy: At the end of a building’s life, the steel can be salvaged and reused without loss of properties.

- Waste Reduction: Precision shed fabrication and component manufacturing ensure that very little material is wasted at the construction site, unlike the debris often associated with concrete formwork.

2.5. Simplified Maintenance

Operational costs are a major concern for facility managers. Fortunately, steel structures are resistant to pests and cracks, requiring only simple maintenance, such as corrosion protection coating which significantly lowers long-term maintenance costs.

- Pest Resistance: Unlike wood, steel is immune to termites and other pests.

- Inorganic Nature: It does not support mould growth or rot, maintaining a hygienic environment suitable for warehouses and food processing plants.

2.6. Application of Steel Structure Building Technology in Industrial Steel Sheds

While steel structure building technology is often associated with large-scale projects such as high-rises or stadiums, the same engineering principles play an equally important role in smaller industrial facilities—particularly steel sheds. As essential components of industrial infrastructure, steel sheds serve as storage spaces, workshops, or auxiliary operation areas. Despite their smaller scale, they benefit from the same durability, load-bearing performance, and structural integrity found in larger steel buildings.

Precision is vital in shed fabrication. High-quality manufacturing ensures airtight and watertight performance, which is crucial for agricultural storage or protecting sensitive equipment. Modern fabrication techniques also allow steel sheds to be modular, enabling rapid installation, easy relocation, and flexible expansion according to project needs. These advantages make steel sheds an effective extension of steel structure building technology within industrial construction.

Steel shed technology brings durable, precise, and modular solutions to industrial projects

The dominance of the steel structure building in the industrial sector is well-founded. By offering a unique synthesis of strength, flexibility, and economic efficiency, steel surpasses traditional building materials.

With the proven advantages of steel structure buildings—ranging from cost efficiency and rapid construction to durability, flexibility, and sustainability—choosing the right execution partner is critical to maximising these benefits. As a leading steel structure fabricator in Vietnam, Pebsteel brings over 30 years of industry experience, supported by advanced manufacturing facilities and strict international engineering standards.

Having successfully delivered thousands of industrial, commercial, and infrastructure projects of various scales, Pebsteel consistently demonstrates its capability in pre-engineered building solutions, complex steel fabrication, and long-span structural systems. This strong track record, combined with a deep understanding of local and international requirements, positions Pebsteel as a reliable long-term partner for investors seeking performance-driven, future-ready steel construction solutions.

To ensure the mosteffective pre-engineered building and steel structure solutions for your project, please contact Pebsteel immediately via email at marketing@pebsteel.com.vn or by phone at (+84) 908 883 531 to receive consultation from our highly experienced engineering team.

Note: The content provided above is for reference purposes only. Structural requirements may vary depending on specific project conditions and locations.