The global demand for infrastructure that is not only quick to construct but also sustainable and highly reliable has reshaped the construction industry. Traditional building methods, often hindered by delays and material waste, are being increasingly replaced by smarter, more efficient solutions. Prefabricated steel building has emerged as a practical response to these modern business needs. Also known as pre-manufactured steel buildings for their systematic, factory-produced nature, they streamline construction with remarkable speed, precision, and minimal waste. Industry leaders, such as Pebsteel, have established high standards of quality and engineering excellence in this sector. This comprehensive guide outlines the complete step-by-step process of constructing a prefabricated steel building, from initial design concepts to the final client handover.

1. Why Prefabricated Steel Buildings Dominate Modern Projects

The popularity of these systems is rooted in their verifiable economic and structural advantages over traditional constru\ction methods. They offer a future-proof solution across industrial, commercial, and agricultural sectors.

Pebsteel’s pre-engineered steel building under construction, demonstrating fast and efficient erection

Time Efficiency

The primary advantage of the prefabricated method is its accelerated timeline. Since most fabrication occurs simultaneously with site preparation, projects achieve significantly faster erection times. Components arrive ready to assemble, eliminating the need for complex on-site cutting and welding. This approach also minimises delays typically caused by adverse weather, making project completion more predictable.

Cost-Effectiveness and Return on Investment (ROI)

While the initial material cost of steel is competitive, the long-term savings are where the ROI shines. The factory environment minimises material waste, and the reduced time required for on-site labour significantly cuts overall labour costs. Furthermore, the standardised manufacturing process ensures predictable budgeting, preventing the cost overruns common in conventional builds.

Superior Durability and Longevity

Steel is naturally one of the strongest construction materials available. Prefabricated steel buildings are engineered to withstand extreme environmental forces, providing exceptional resilience against high winds and seismic activity. Unlike timber, steel is completely resistant to pests, rot, and decay, ensuring a structure that retains its integrity and requires minimal maintenance throughout its long lifespan.

Design Flexibility and Adaptability

The structural integrity of steel enables clear-span design, creating open, column-free interior spaces that are highly valued in industrial and commercial settings, such as warehouses or manufacturing plants. This structural flexibility also means that a prefab steel building can be easily adapted, expanded, or modified in the future with minimal disruption, protecting the client’s investment.

Sustainability and Environmental Impact

In an era focused on green building, steel offers a compelling advantage: it is 100% recyclable without loss of quality. The use of pre-manufactured steel buildings reduces on-site disruption, lowers the material transport footprint, and minimises construction waste destined for landfills, positioning this method as a highly sustainable choice.

Find Out More: Steel Building PEB Guide – Structure, Codes, and Construction Steps

2. The Complete 13-Step Process of Prefabricated Steel Building Construction

Prefabricated steel buildings offer fast construction, cost efficiency, and durability, making them ideal for industrial and commercial use. The success of these systems hinges on the execution of a streamlined, phase-driven process that ensures quality at every stage.

Step 1: Defining Requirements and Conceptual Design

The process begins with a thorough client consultation to determine the purpose, size, aesthetic goals, and functional requirements of the facility. This is followed by essential feasibility studies, which consider zoning regulations, access to utilities, and preliminary structural analysis based on the building’s intended use, such as a high-load warehouse or a multi-story office. During this phase, the building requirements are clearly defined, structural steel designs are created using Building Information Modelling (BIM) and Computer-Aided Design (CAD), and budgets and timelines are established. This initial stage sets the foundation for the entire project.

Conceptual planning and design stage of a prefabricated steel building project for industrial construction

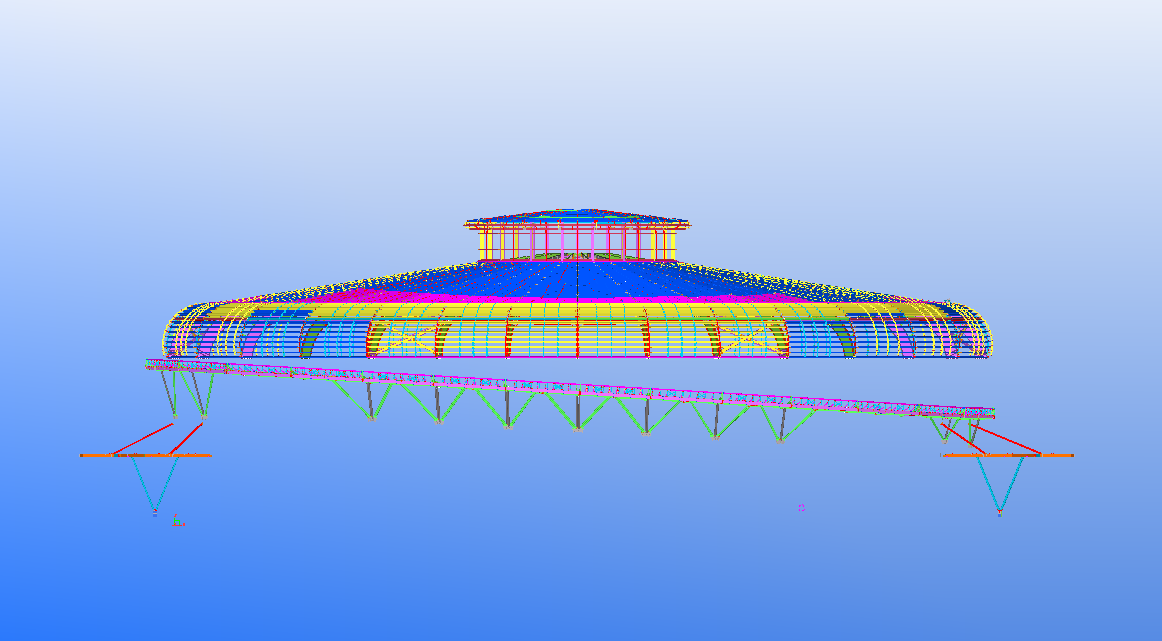

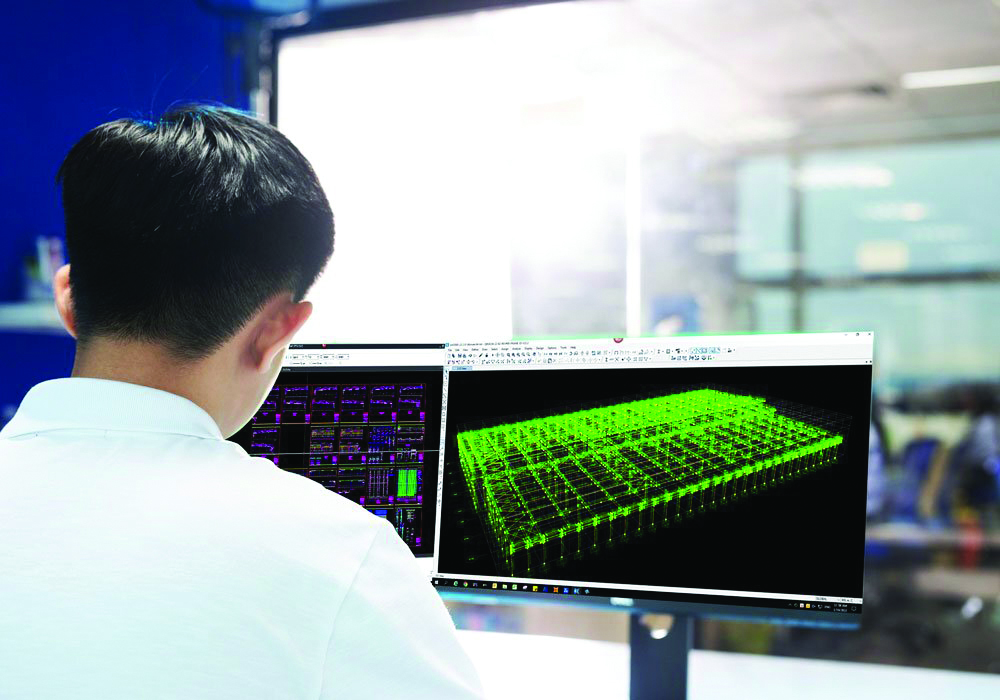

Step 2: Advanced Structural Design and BIM Integration

Engineers utilise state-of-the-art tools, such as Building Information Modelling (BIM) and Computer-Aided Design (CAD), to translate the concept into a highly accurate, three-dimensional model. This stage involves generating detailed engineering drawings and precise component lists. Critical calculations for site-specific environmental loads—such as wind and seismic forces—are rigorously performed to guarantee structural integrity and code compliance. It is this technological precision that defines a top-tier prefabricated steel building.

BIM integration in steel building structural design

Step 3: Procurement Strategy and Project Scheduling

With the design finalised, the project management team initiates the procurement of high-quality raw materials and specialised components. Simultaneously, the Critical Path Method (CPM) is employed to finalise the master timeline and budget. This strategic scheduling ensures materials arrive at the factory and site precisely when needed, minimising idle time and maximising efficiency.

Step 4: Comprehensive Site Assessment and Groundwork

Preparation on the ground is the first physical step, requiring its own layer of technical precision. Before any excavation, detailed geotechnical surveys are carried out to analyse soil composition and bearing capacity. Professional land surveying confirms the exact boundaries and topography of a property. Engineers survey the land conditions, then clear and level the site before constructing foundations designed for steel structures. Following the assessment, the site is cleared, precisely graded, and compacted to create a stable, ready-to-build platform.

The prefabricated steel building is in the first stages of construction.

Step 5: Constructing the Specialised Foundation

The foundation is designed as a custom base to anchor the pre-manufactured steel building’s frame. Unlike heavy conventional foundations, these are optimised for the predictable load distribution of steel. This stage involves pouring and curing concrete foundations (such as slabs, piers, or strip footings) and, most critically, setting the anchor bolts with extreme precision. The slightest deviation in anchor bolt placement can compromise the entire rapid erection process.

Step 6: Cutting-Edge Fabrication Techniques

This is the core value proposition: controlled, high-quality production away from the variability of the construction site. Manufacture steel columns, beams, and panels with CNC precision and conduct strict quality checks. In the factory, state-of-the-art CNC (Computer Numerical Control) machinery is used for every process—from plasma cutting and punching bolt holes to welding fabricated according to custom design specifications. This level of automation ensures every steel member possesses millimetre-level dimensional accuracy.

Step 7: Protective Coatings and Quality Assurance (QA)

A crucial step in ensuring longevity is the application of protective coatings. Primers and specialised corrosion-resistant finishes (such as zinc-rich epoxy) are applied in a controlled factory environment. A rigorous Quality Assurance (QA) protocol is implemented, where inspectors verify the integrity of every weld, confirm dimensional tolerances against the BIM model, and verify coating thickness before the components are cleared for shipment.

Step 8: Logistics, Transportation, and Staging

The components are systematically packaged and loaded onto transport vehicles, using specialised methods to prevent any deformation or shifting during the journey. Safely transport prefabricated components to the site, ensuring that they arrive without damage or deformation. Upon arrival, the parts are efficiently staged in a sequence that matches the erection schedule, ensuring rapid access and minimising delays.

Step 9: Rapid Erection of the Main Frame

Utilising heavy-duty cranes and specialised lifting gear, the primary columns and rafters are quickly lifted into position and secured to the anchor bolts. Erect the main steel frame, install secondary structures, and secure all joints with bolts and welding. Experienced erection crews then install temporary bracing and conduct alignment checks to verify the frame is plumb and square before permanent connections are made.

Step 10: Installation of Secondary Structures and Bracing

Once the main frame is secure, secondary structural elements are installed. These include purlins (which support the roof), girts (which support the walls), and various eaves struts. Crucially, cross-bracing systems are installed throughout the roof and walls to provide essential lateral stability against horizontal forces, such as wind and seismic activity.

Step 11: Weatherproofing and Envelope Completion

High-performance roofing systems and insulated wall panels are installed to create a weather-tight and thermally efficient building envelope. Install roofing sheets or insulated panels and construct exterior walls with durable, weather-resistant materials. Advanced sealing techniques are applied to all joints, flashings, and transitions to ensure superior weatherproofing and energy efficiency throughout the structure’s lifetime.

Roof cladding installation on the prefabricated steel building, enhancing its weatherproof envelope

Step 12: Utility and Interior Integration

The final phase transforms the raw structure into a fully functional facility. During this stage, doors, windows, ventilation systems, lighting, and protective coatings are installed to ensure long-term durability. Essential utilities such as electrical wiring, plumbing, and HVAC systems are also fully completed.

Step 13: Final Inspection, Testing, and Documentation

The project concludes with a final, meticulous structural integrity check and safety inspection. Inspect the completed structure, finalise testing, hand over to the client, and provide maintenance guidelines. The client then receives the completion documents, comprehensive warranties, and detailed maintenance guidelines—a hallmark of quality providers like Pebsteel.

The step-by-step process ensures precision, safety, and efficiency, proving prefabricated steel buildings are the smart choice for modern projects.

3. Key Applications of Prefabricated Steel Structures

The adaptability of prefabricated steel buildings makes them the preferred choice across a vast array of industries.

- Industrial: Facilities are the backbone of modern logistics and manufacturing, ideal for the vast, clear-span spaces required by warehouses, heavy manufacturing factories, and large-scale distribution centres.

- Commercial and Retail: From sleek showrooms and expansive retail strip malls to modern, multi-story office complexes, steel offers the necessary speed of construction and design flexibility to meet commercial deadlines and aesthetic goals.

- Specialised Uses: The structures’ inherent strength makes them perfect for specialised, high-demand applications, including aircraft hangars, durable sports facilities, and large-capacity agricultural storage buildings.

Prefabricated steel building is applied to many different applications

4. Frequently Asked Questions (FAQs) about Prefabricated Steel Buildings

4.1. Is a Prefabricated Steel Building More Cost-Effective Than Traditional Construction?

Yes, in most cases. While the cost of raw materials may vary, substantial savings are achieved through significantly reduced construction time, often 30 to 50 per cent faster, and minimal material waste thanks to the precision of factory production.

4.2. How long does it take to construct a pre-manufactured steel building?

The timeline varies by size, but on average, the on-site erection time for the steel frame is drastically reduced. A medium-sized facility can often be erected and enclosed in a matter of weeks, compared to the months it takes to construct a conventional building.

4.2. What is the lifespan of a prefabricated steel building?

When properly engineered and maintained, a high-quality prefabricated steel building can last 50 to 100 years or more. The use of specialised protective coatings in the factory ensures long-term resistance to corrosion, providing exceptional durability.

The construction process of a prefabricated steel building demonstrates modern efficiency in practice. This structured, multi-phase approach, covering detailed engineering through to final handover, ensures precise assembly, strict adherence to safety standards, and optimal efficiency. Every component, from the main columns to the smallest bracing members, is designed for performance and rapid installation.

By choosing a pre-manufactured steel building solution from an industry leader such as Pebsteel, a trusted steel structure fabricator in Vietnam with strong expertise in structural steel design, clients are not just commissioning a structure; they are investing in a high-quality, efficient, and sustainable solution that is prepared to meet future demands.

Do you require a comprehensive solution for your next steel building construction project? Please contact Pebsteel immediately via email at marketing@pebsteel.com.vn or by phone at (+84) 908 883 531 to receive expert consultation from our highly experienced engineering team.

This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.