A steel building is a structure in which the primary load-bearing system is made of structural steel, typically consisting of columns, beams, rafters, and bracing. Designed through structural steel design principles that optimise strength-to-weight efficiency, steel buildings provide exceptional durability, design flexibility, and significantly faster construction timelines compared to traditional building materials.

Today, steel buildings are widely used across various sectors, including industrial, commercial, and even residential. They are the preferred choice for warehouses, factories, logistics centres, aircraft hangars, retail complexes, parking structures, and large-span public facilities. Their ability to achieve long clear spans, accommodate diverse architectural forms, and support future expansion makes steel buildings a highly practical solution for modern construction demands, particularly in markets with a strong manufacturing base such as steel structure fabrication in Vietnam.

This article of Pebsteel provides a comprehensive steel building guide, covering its definition, core components, advantages, industry standards, and the key applications that make this structural system increasingly essential in contemporary construction.

1. What Defines a Pre-Engineered Steel Building (PEB)?

A pre-engineered building (PEB), often referred to interchangeably as a prefab steel building, is a structure where the lightweight yet high-strength steel frame constitutes the entire primary load-bearing system. This specialised method represents a major shift from conventional construction, emphasising precision and speed.

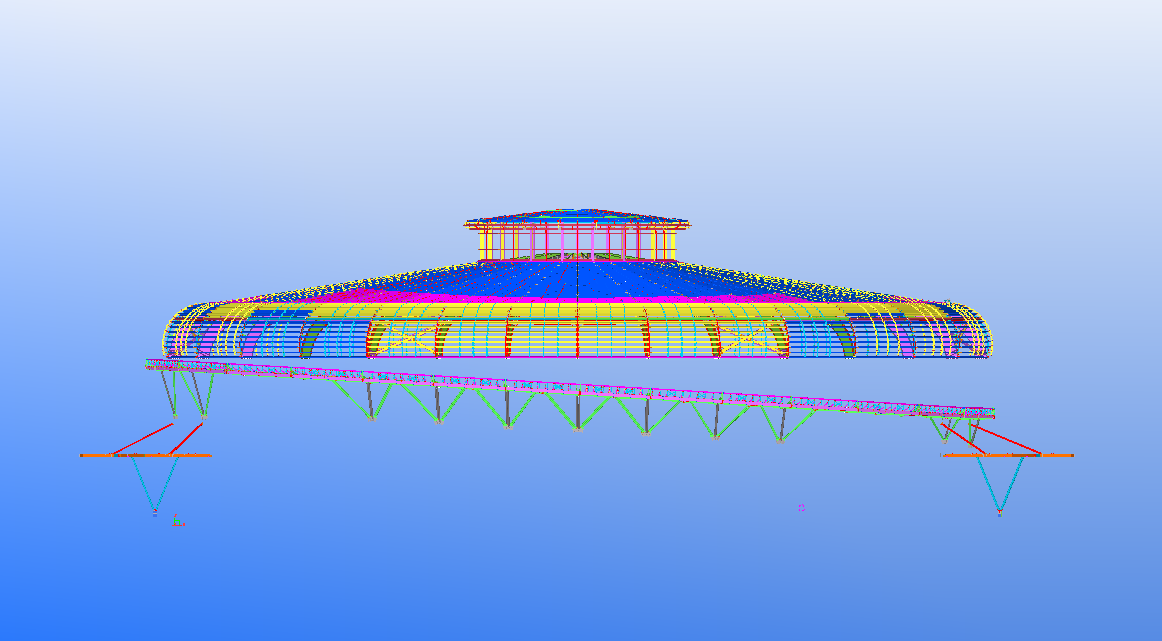

The structural elements, including the columns, rafters, bracing, purlins, and base plates, are meticulously designed using advanced software and then manufactured as pre-manufactured steel building components within a controlled factory setting. The resulting parts are then transported to the project site, where the construction team undertakes rapid assembly and bolting according to the approved engineering drawings.

This streamlined methodology offers profound benefits:

- Quality Control: Fabrication in a factory environment ensures superior weld quality and dimensional accuracy, reducing defects.

- Time Efficiency: The quick, bolt-together assembly process significantly shortens the construction timeline.

- Future Flexibility: The system inherently facilitates easy future expansion or modification of the structure.

The versatility of this steel building solution makes it a preferred choice across diverse sectors. It is highly popular for large-span industrial workshops, high-capacity warehouses, regional distribution centres, multi-story car parks, sports arenas, transportation terminals, retail showrooms, and even for structurally sound vertical extensions to existing homes. Investors consistently select this system due to its accelerated progress, overall competitive costs, and its reduced negative impact on the environment, solidifying its status as a preferred modern construction solution.

A steel building under construction by Pebsteel

2. Global Standards for Quality and Safety in Steel Buildings

To guarantee the long-term safety, structural performance, and reliability of pre-engineered building projects, specialised regulatory bodies mandate stringent construction standards. For a professional contractor like Pebsteel, compliance with these local and international codes is essential, providing definitive assurance to the client.

In Vietnam, contractors typically adhere to TCVN standards. However, for projects destined for international markets or those requiring global quality assurance, strict adherence to codes such as AISC 303-22, AWS D1.1, and MBMA is mandatory.

2.1. TCVN 5575:2012 – Vietnam’s Foundational Steel Structure Standard

TCVN 5575 serves as the foundational standard for steel structure within Vietnam, used by contractors for construction and final acceptance testing by specialised state agencies. Adherence requires precise compliance with specified steel grades, the configuration of welded and bolted connections, and the assurance of overall structural stability. All fabricated components must be clearly detailed in the technical drawings, meeting TCVN reference benchmarks.

A common challenge arises when project documentation mixes TCVN with international requirements, leading to potential interpretation conflicts. The professional solution is to establish a unified set of criteria in the construction methodology, explicitly citing which clauses from which standard will be used for final acceptance.

All Pebsteel projects must comply with strict standards in Vietnam and internationally

2.2. AISC 303-22 – Code of Standard Practice for Steel Structures

Issued by the American Institute of Steel Construction (AISC), this standard outlines the rules of engagement between project parties, with a strong emphasis on permissible dimensional tolerances during fabrication and erection. This includes standards for alignment, plumbness, elevation, and axis location.

To comply with AISC 303-22, construction teams must accurately record tolerance indicators, utilise precise measuring equipment (like total stations), and define clear protocols for deviation correction. The major hurdle is often schedule pressure, which can lead to the accumulation of systemic errors. Experienced steel building contractors mitigate this by performing measure-adjust-lock procedures sequentially and ensuring the main frame meets tolerance before roofing commences.

2.3. MBMA Metal Building Systems Manual (MBSM)

The MBSM, published by the Metal Building Manufacturers Association (MBMA), is the definitive code governing the construction of prefabricated steel building systems. This comprehensive manual details frame configurations, purlin/bracing requirements, roof/wall systems, framed openings, temporary stability, and critical weatherproofing details.

The prescribed erection sequence in MBSM is crucial: setting the primary frame, locking it via bracing and purlins, and then installing the cladding. The manual also provides clear guidelines for water-tight sealing at the ridge cap, flashing, roof penetrations, and gutters. Compliance challenges often stem from discrepancies between local climate conditions and the standard, compounded by congested sites and constantly shifting lifting schedules. The primary risk is structural instability due to a lack of temporary bracing. The remedy involves adhering strictly to a standard assembly bay and having comprehensive temporary bracing kits prepared.

2.4. AWS D1.1 – Structural Welding Code – Steel

AWS D1.1 is the essential regulation used to evaluate the quality of structural field welding. Standards to be met include the approved Welding Procedure Specification (WPS), Procedure Qualification Records (PQR), welder certifications, and non-destructive testing (NDT) methods, such as Magnetic Particle Testing (MT), Liquid Penetrant Testing (PT), and Ultrasonic Testing (UT).

The primary challenge lies in rigorously controlling the environmental conditions, as wind, humidity, and temperature significantly compromise weld quality. Additionally, maintaining valid certifications for all field personnel is an administrative task that requires meticulous oversight. Contractors must implement controlled welding shelters, manage the ambient environment, and factor in repair time for non-conforming welds.

Standard structural steel is being produced at Pebsteel’s factory

2.5. ISO 12944 – Corrosion Protection and Paint Standards

To address the necessary standards for paint and anti-corrosion materials, which are a critical element for the longevity of pre-manufactured steel buildings, contractors utilise ISO 12944. Key focus areas include environmental classification (C2 to C5/CX), coating system selection, surface preparation, and specified Dry Film Thickness (DFT) based on the desired service life.

Obstacles to compliance often involve accurately determining the environmental class, achieving the required surface cleanliness standard (for instance, Sa 2.5), applying local paint boosts at edges and welds, and frequently measuring the DFT. Environmental factors, such as dew, high humidity, and construction dust, pose significant threats to the coating’s integrity. To ensure compliance, contractors must regularly calibrate measuring tools and strictly control the environment during application.

The construction of large-scale industrial workshops and facilities is a rigorous test of a contractor’s ability to meet all the aforementioned standards simultaneously. These projects are characterised by vast areas and a heightened urgency for rapid deployment (to quickly bring the factory online), all while remaining within the client’s approved budget. Compliance with these standards across massive scale, high speed, and cost constraints is what differentiates a truly professional steel building partner.

For Your Information: Trusted Structural Steel Fabricator: Customized Steel Structure Solutions

3. Critical Requirements for High-Quality Pre-Engineered Building Execution

When constructing a prefab steel building, contractors must adhere to specific requirements across the entire lifecycle of the project. Applying these stringent controls not only guarantees the structure’s superior quality upon completion but also ensures rigorous control over the project budget and deployment schedule, solidifying the professional standing of the contractor.

Steel manufacturing process to ensure the highest standards for pre-engineered steel buildings

3.1. Requirements for Materials and Ancillaries (Input Control)

Input control is essential for ensuring the long-term integrity of any modern steel building. Contractors must obtain complete documentation, including certificates for all primary materials such as structural steel, purlins, sheeting or panels, high-strength bolts, and coating systems. All materials must strictly conform to the specified grade, thickness, and coating layers outlined in the technical drawings.

For stored items, particularly pre-manufactured steel building components, construction teams must use dry, elevated, and covered storage areas with proper ventilation to prevent moisture accumulation and corrosion. Supervising parties have the right to perform random checks on dimensions, coating thickness, and batch markings. For critical material lots, additional testing may be required before use. These stringent measures are necessary to comply with all pre-engineered building construction standards and to minimise quality discrepancies during final acceptance.

3.2. Requirements During Execution (The Construction Phase)

The execution phase requires meticulous attention to sequence and detail to maintain the integrity of the steel building design.

- Foundational Check: Before erecting any steel frame, the surveying team must verify all control points, elevation benchmarks, grid lines, and the correct placement of anchor bolts.

- Erection and Stabilisation: The structure must be erected sequentially, starting with columns and rafters, and immediately stabilised using bracing and purlins before installing any cladding or sheeting.

- Waterproofing: Critical junctions, including ridge caps, flashing, and roof penetration, must be sealed carefully to ensure maximum water-tightness.

- Connection Integrity: All field welding must strictly follow the approved Welding Procedure Specification. High-strength bolts must be tightened using the proper method, such as tension control bolts or the turn-of-nut technique, and verified through pull-testing or torque wrench inspection.

3.3. Requirements for Final Acceptance (Output and Handover)

Final acceptance of the pre-engineered building focuses on verifiable compliance across all phases. The acceptance authority must perform a comprehensive dimensional survey, measuring erection tolerances against standards for plumbness, straightness, elevation, and axis location.

Crucial documentation must be reviewed, including:

- Bolt tightening records.

- Non-Destructive Testing (NDT) reports for field welds.

- Dry Film Thickness (DFT) reports for coatings.

The comprehensive handover file required from the contractor includes the construction log, all material certifications, item acceptance minutes, final as-built drawings, and a detailed maintenance guideline. During acceptance, the supervising unit must reference the latest applicable steel building structure standards, clearly stipulating the acceptable tolerance thresholds for each compliance metric to ensure total project adherence.

4. The Seven-Step Construction Process for a Pre-Engineered Steel Building

Executing a pre-engineered building project requires strict adherence to a defined, phased procedure to guarantee construction quality, ensure timely project completion, and maintain budgetary control. Pebsteel outlines the following seven-step construction sequence, enabling clients to effectively monitor and supervise the contractor during upcoming steel building projects.

Pebsteel’s steel house construction follows a scientific construction process, ensuring quality for customers

Step 1: Site Readiness and Material Preparation

This initial phase ensures the site and materials are certified and ready for mobilisation. The contractor must perform precise surveying, formally receiving handover of control benchmarks and elevations. Essential preparation includes verifying material conformity to specifications, mobilising all components to the construction site, establishing the hoisting and erection plan, setting up the staging area, and standardising measurement forms for the Quality Assurance/Quality Control (QA/QC) department to monitor both material quality and the installation process.

Step 2: Primary Frame Erection and Stabilisation

This stage focuses on establishing the core structural integrity of the prefab steel building. The construction team erects the primary frame by:

- Installing columns and rafters in the predefined sequence.

- Using temporary bracing and turnbuckles, which are adjustable tensioning fittings, to stabilise the frame against lateral loads.

- Performing initial measurements, adjustments, and temporary tightening before proceeding to the next section of the frame.

- Installing permanent column bracing, roof bracing, and eave struts or horizontal bracing to create a fully stable three-dimensional structural system.

Step 3: Secondary Framing and Alignment

Once the primary structure is stable, the secondary framework is installed. This includes setting the C/Z purlins (often with required overlaps), completing the eave struts and sag rods, and implementing the diagonal bracing to lock the bay spans. The team must verify structural squareness via diagonal measurement and reinforce any necessary framed openings for future door or window installation.

Step 4: Cladding, Sheeting, and Weatherproofing

This is the stage where the structure becomes weather-tight.

- Installing corrugated steel sheets or insulated panels along the standardised edge.

- Utilising self-drilling screws, EPDM rubber washers, and sealant for secure and water-tight fastening.

- Completing all necessary accessories: ridge caps, flashing, gutters, downspouts, and wind screens.

- Crucially, collecting all metal swarf (shavings) immediately to prevent rust staining and corrosion of the new cladding.

Step 5: Connection Integrity and Quality Inspection

This critical step guarantees the long-term load-bearing capacity of the steel building.

- Welding: All field welding must conform strictly to the approved WPS/PQR, with Non-Destructive Testing (NDT) such as MT, PT, or UT conducted according to a specified ratio.

- Bolting: High-strength bolts are initially tightened to a snug-tight condition, followed by final tightening using either the turn-of-nut method or tension control (TC) bolts to verify the exact tension force.

- Calibration: All tightening and measuring tools must be calibrated prior to mass execution to ensure accuracy.

Step 6: Corrosion Protection and Finishing Touches

This phase focuses on the final surface protection and sealant details. The contractor must clean the surface to the required standard, for example, Sa 2.5. Touch-up paint must be applied correctly using the specified coating system, and the dry film thickness should be measured, with particular attention to cut edges and weld areas. Final tasks include cleaning gutters and drains, as well as installing additional gaskets and edge sealants to ensure a complete and effective weatherproof seal.

Step 7: Final Acceptance, Handover, and Closeout

The final step involves the rigorous verification of the finished pre-engineered building and the formal handover to the client.

- Final Survey: The structure is checked against design specifications for plumbness, straightness, roof elevation, axis spacing, and squareness.

- Documentation: All quality records are finalised, including the construction log, bolt tension reports, NDT reports, DFT reports, and the as-built drawings.

- Handover: A final punch list of outstanding items is generated, corrected, and the project is formally handed over to the client, complete with comprehensive maintenance guidelines.

5. Frequently Asked Questions (FAQ) on Steel Building Construction Standards

Below are the most frequently asked questions regarding the technical and regulatory aspects of pre-engineered building construction. This section aims to provide rapid and direct answers to common inquiries.

5.1. Which standards are commonly applied during steel building construction in Vietnam and internationally?

In Vietnam, prefab steel building contractors often reference TCVN 5575. For projects requiring global compliance, multiple international codes are referenced simultaneously: AISC 303-22 (for tolerances and coordination), the MBSM manual (specifically used for pre-engineered building systems), AWS D1.1 for welding quality, and ISO 12944 for anti-corrosion coating systems. Referencing these codes concurrently ensures the steel building project meets both national and international stipulations.

5.2. What constitutes the standard acceptance criteria for a steel building?

The final acceptance package provided by the contractor forms the “backbone” of the acceptance standard. This crucial handover documentation includes verifiable evidence of:

- Erection tolerance measurements (AISC/MBMA standards).

- Records verifying the tensioning of high-strength bolts.

- Non-Destructive Testing (NDT) reports for field welds (AWS D1.1 compliance).

- Dry Film Thickness (DFT) reports for coatings (ISO 12944 compliance).

These reports are submitted alongside the final as-built drawings and the project construction logbook.

Steel building uses steel structures, so that upon acceptance, the project fully meets the strict standards of the investor

5.3. What are the acceptance standards for structural steel material input?

The contractor must provide certificates of conformance for all input materials, including structural steel, purlins, panels/sheeting, bolts, and the paint system. The supervising party conducts random checks on dimensions, coating thickness, and batch stamping, comparing them against design drawings and relevant standard clauses. Implementing strict material input standards is the most effective quality control measure to guarantee that the finished pre-manufactured steel buildings meet investor expectations.

5.4. should one select a reputable and compliant pre-engineered building contractor?

You should prioritise a contractor that demonstrates a clear Quality Assurance/Quality Control (QA/QC) system, utilises certified welders, has site-specific erection plans, detailed safety protocols, and transparent handover documentation (including tolerances, NDT, DFT, and bolt records). A reliable portfolio of previously completed projects is the most trustworthy benchmark, especially when seeking a reliable steel building contractor for a new venture.

With over 30 years of experience and partnerships with world-leading corporations across more than 50 countries, including Heineken, Samsung, P&G, and Unilever, Pebsteel is committed to delivering high-quality pre-engineered building projects that are on schedule, cost-optimised, and aesthetically pleasing. With six large factories in Vietnam, each with a total annual steel production capacity exceeding 100,000 tons, Pebsteel is well-positioned to execute projects nationwide, providing flexible solutions that meet the requirements of every client.

Do you require a comprehensive solution for your next steel building construction project? Please contact Pebsteel immediately via email at marketing@pebsteel.com.vn or by phone at (+84) 908 883 531 to receive consultation from our highly experienced engineering team.

This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.