Nowaday, the factory is used a lot in works ranging from civil to industrial. Depending on the needs, customers can choose small and large factory designs that are suitable for space and cost. Join Pebsteel to find out the details of quality and economical small factory designs in 2025 through the following article.

1. Advantages of small prefabricated steel factory

Designing small factories is a great solution to effectively save costs. For this reason, many businesses have chosen the small factory model to meet their specific needs, optimizing time, costs, and functionality.

- Optimizing space: Small factories can be used for a variety of purposes such as production places, warehouses and office combinations to help users make effective use of the space. The steel components are easy to install, upgraded and suitable for investors who wish to expand the size of the factory.

- Cost savings: Small prefabricated steel factories are lighter in weight than traditional reinforced concrete factories which reduces the load on the foundation. As a result, it will optimize the cost of foundation treatment materials for customers.

2. Steps to Design a Small Factory

Designing a factory is an important and mandatory step to complete the construction. Regardless of the scale, whether small, medium, or large, factory design is always carried out in two main stages: basic design and construction drawing design.

Basic Design of a small factory

Basic design for a small factory includes:

- Basic design explanation:

- General information about the construction site: layout, scale, construction items.

- Basic design plan, structure, infrastructure system, technical system, environmental protection, and fire prevention and fighting according to regulations.

- Connection plan between construction items and technical infrastructure.

- You might be interested: Fire prevention and fighting permit service.

- Basic technical design drawings:

- Overall factory layout drawing.

- Infrastructure, technical, and main structure design drawings of the factory.

- For factories with architectural requirements, additional architectural design drawings will be needed.

Construction Drawing Design

Construction drawing design for a factory requires architects to base their work on actual estimates and survey documents, meeting the following requirements:

- Detailed and clear with full technical specifications.

- Structural details must comply with standards.

- Ensure that the materials used meet the conditions for construction implementation.

Foundation Construction

To have a safe and quality factory, the foundation is a crucial factor. The foundation is usually located at the bottom of the construction to ensure it can withstand the pressure of the building during construction and human activities.

Steel Frame and Accessories Installation

The installation of equipment must be careful because even a small mistake can cause the construction to be misaligned. Before performing this step, carefully observe the surroundings to ensure the operation area is clear. This is the backbone of the factory.

Technical System Construction

After completing the steel frame, proceed with the construction and covering of the building. This step helps protect equipment, machinery, and personnel from external environmental impacts. Additionally, it helps secure the production processes, preventing unauthorized access.

Cleaning and Acceptance of the Factory

After construction is completed, cleaning is an indispensable step as it reflects the meticulousness and attention to detail in the work. The acceptance step after construction is also very important to check if there are any errors in the construction to be promptly corrected.

3. Basic prefabricated small steel factory structure

Usually, small prefabricated factory designs are designed in a structure of 4 parts:

Foundation: Solid reinforced concrete is the main material to build the foundation which has the effect of supporting, bearing the whole building above.

Frame system: includes truss frame, bracing system and purlins designed according to technical drawings with supporting functions, helping to stabilize the steel structure, and increase the durability of the building.

Corrugated Steel Roof: With the basic use of covering while enhancing the function of insulation, anti-leakage for the interior space, the roofing system includes basic materials such as corrugated steel wall, corrugated steel roof, insulation roof, …

Substructures and accessories: small prefabricated factories also have sub-structures such as roof top ventilation system, roof, door, louver, walkway, cage ladder,…

4. Popular Small Factory Designs in 2025

4.1. 1200m2 Small factory design

The 1200m2 small prefabricated steel factory has a fast installation time, saving construction costs.

4.2. 1500m2 Small factory design

The area of the 1500m2 factory is very suitable for the needs of material factories, machinery installation areas, warehouse constructions…

4.3. 1800m2 Small factory design

The 1800m2 small factory is simply designed, easy to install, suitable for making warehouses, workshops, garages,…

4.4. Small corrugated steel factory design

Small corrugated steel factories often use corrugated steel for both the wall and roof with the advantages of saving costs and optimizing construction time.

4.5. Concrete factory design with corrugated steel roof

The small factory has a corrugated steel roof combined with an average of 2.5m high concrete walls. With the advantages of durability and certainty, concrete materials partially restrict the abrasion and degradation of the building.

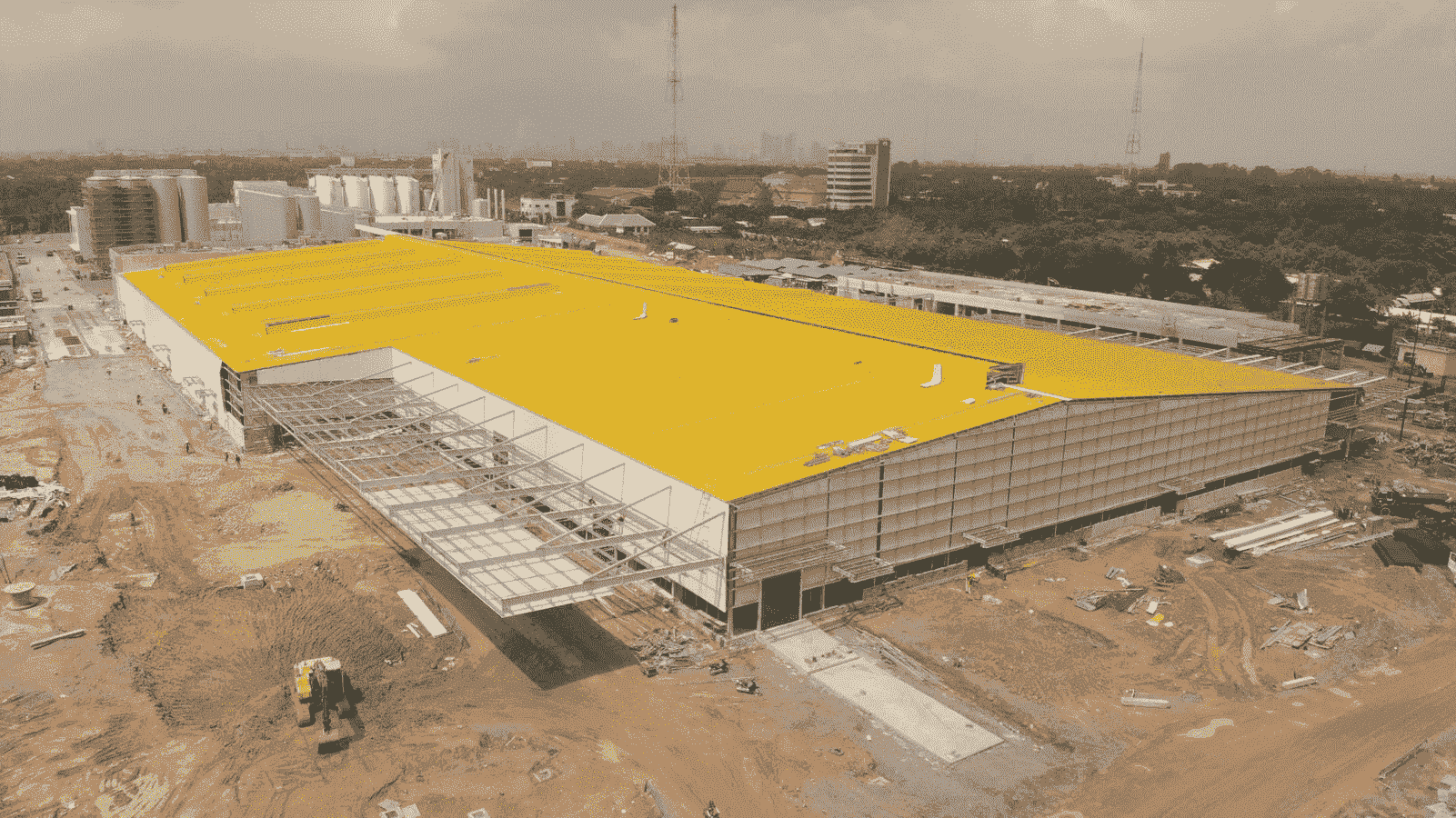

4.6. Prefabricated Steel Industrial Factory Model

The popular small industrial factories are designed with many surrounding windows, the top of which can be skylights to help get better light. Industrial factories often have corrugated steel roofs installed with wind roofs to help the factory always be airy and not be damp. The door of the industrial factory is usually extensively designed and convenient for transportation.

4.7 Small factory design with mezzanine or 1 floor

In order to maximize the usable area, small factories are often equipped with Mezzanines or standard floors. Reinforced steel-concrete conjugate floor (also known as deck floor) for mezzanine floor and standard floor is the most popular choice besides 100% reinforced concrete structure. As a result, the investor has more space for the storage of goods as well as the combination of small offices inside the factory.

Pebsteel – A quality small factory construction unit in Vietnam

Pebsteel is a quality prefabricated steel factory with 31 years of experience and has constructed more than 6000 different scale works in many countries vietnam, Thailand, Laos,… We are committed to bringing customers satisfaction to the small factory building prefabricated quality.

The above is information we share that relates to the popular, economical small factory design in 2025. If the customer has any questions that need to be answered about prefabricated steel buildings or structural steel design please contact at the following email: marketing@pebsteel.com.vn or phone number +84 908 883531 for specific advice from Pebsteel.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.