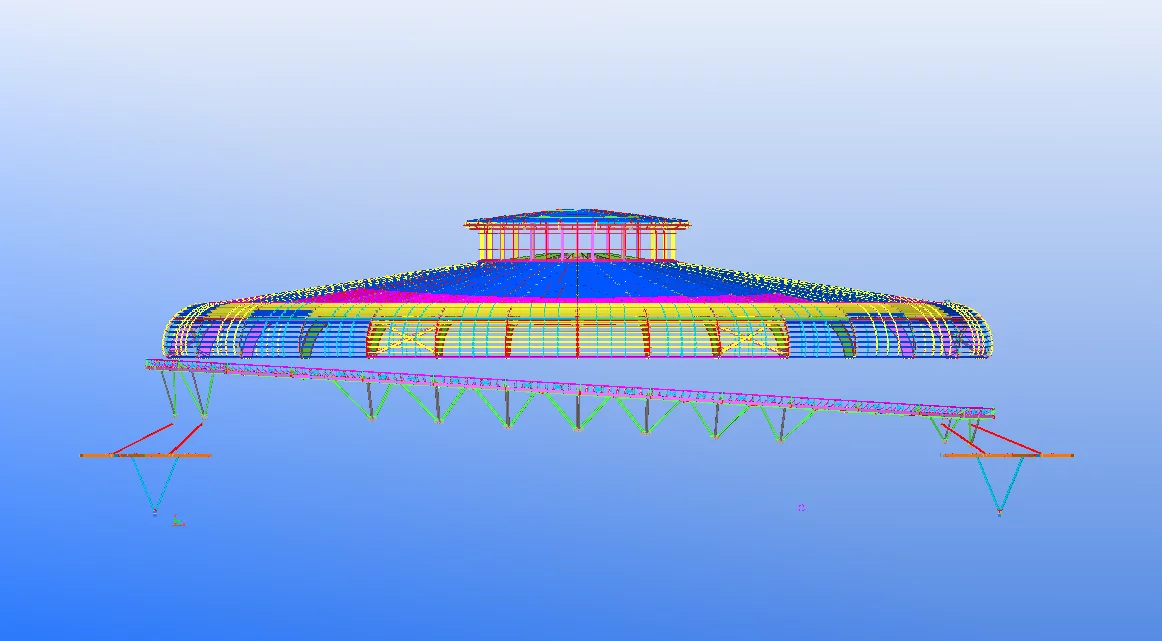

Constructing a modern industrial facility or warehouse demands a structural solution that is fast, cost-effective, and strong, which is why pre-manufactured steel buildings have become so popular. However, the long-term success of these advanced structures, from simple storage sheds to complex multi-span factories delivered by leading suppliers like Pebsteel as a steel structure fabricator in Vietnam, depends heavily on one critical factor: selecting the right foundation for steel prefabricated buildings. An inappropriate foundation choice can lead to unnecessary costs, construction delays, and serious structural risks, making this decision a high-stakes part of any project. This guide provides a clear framework that links geotechnical data, site conditions, and structural loads to the most suitable foundation types, explaining components, pros and cons, and key construction notes to ensure long-term operational stability.

1. The Critical Role of the Foundation for a Pre-Engineered Steel Building

The structural integrity and longevity of any construction project depend fundamentally on its foundation. This is especially true for prefabricated steel building foundation systems. A foundation acts as the essential interface between the superstructure, which is the pre-manufactured steel building frame, and the underlying soil. Its main function is to safely transfer all loads from the building to the ground without causing excessive settlement, rotation, or shear failure.

The loads considered include:

- Dead Load (DL): The weight of the building materials themselves (steel frame, roofing, walls, floor slab, etc.).

- Live Load (LL): The weight of occupants, furniture, equipment, or stored materials.

- Environmental Loads:

- Wind Load (WL): Critical for tall or large-span prefab steel building foundation designs, as steel structures are relatively lightweight and prone to uplift.

- Seismic Load (SL): Forces generated by earthquakes.

A well-designed foundation prevents structural movement that could lead to distortions in the steel frame, cracking in the floor slab, or failure of cladding systems. For a specialist in pre-engineered steel structures, like Pebsteel, ensuring the foundation design aligns perfectly with the frame’s anchor points and specified loads is non-negotiable for project success.

A Pebsteel project is constructing the foundation of a prefabricated steel buiding

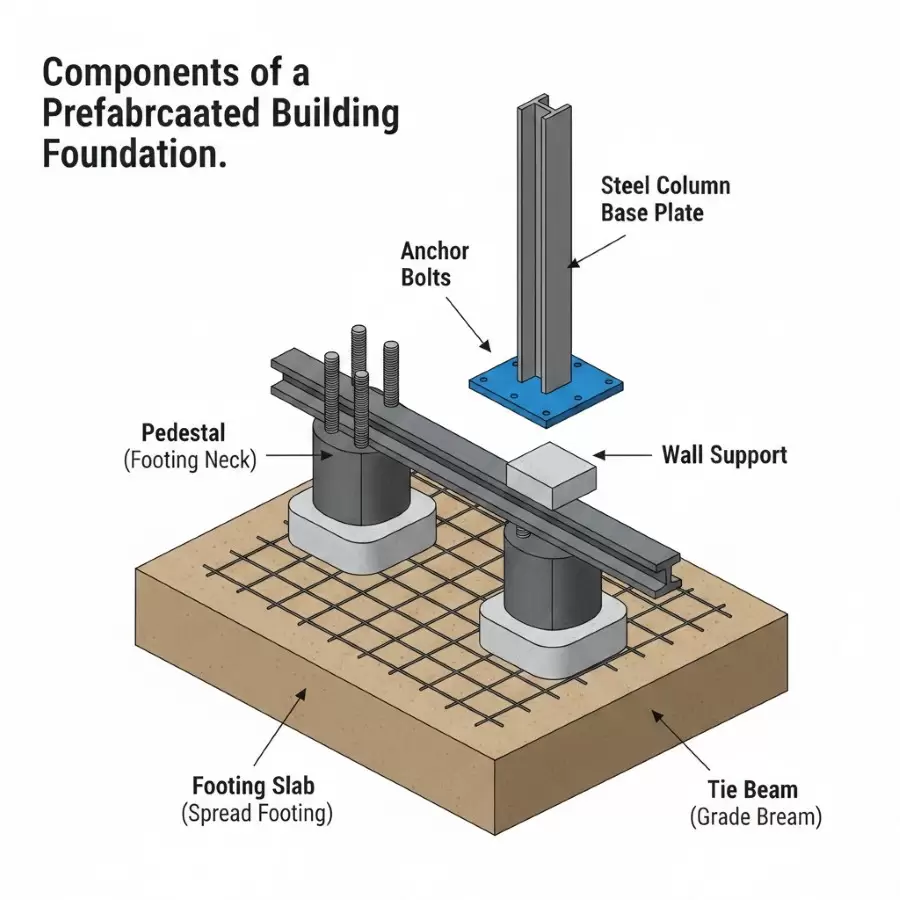

2. Components of a Prefabricated Building Foundation

While the final foundation type varies, most foundation for steel prefabricated building designs share common primary components necessary to anchor the structural steel design effectively.

Footing Slab (Spread Footing)

The footing slab is the base component that directly rests on the prepared soil. Its function is to distribute the concentrated column loads over a sufficiently large area of soil, ensuring the pressure exerted is less than the soil’s bearing capacity. Footings can be square, rectangular, or circular, depending on the load and geometry of the column or wall.

Tie Beam (Grade Beam)

Tie beams, often referred to as grade beams, are reinforced concrete beams spanning between individual footings or pedestals. They serve several crucial functions:

- Lateral Stability: They tie the individual footings together, making the entire foundation system act as a cohesive unit. This is vital for resisting lateral forces (like wind or seismic) and differential settlement.

- Wall Support: They provide direct support for the wall cladding or brickwork, often spanning the perimeter of the building.

- Anchor Point Integration: They can be designed to incorporate anchor bolts that connect the steel column base plates to the foundation, ensuring a secure connection.

Pedestal (Footing Neck)

The pedestal is a short, reinforced concrete column that rises from the footing slab to the level of the steel column base plate.

- Elevation: It raises the steel base plate above the finished floor level and the ground, protecting the steel column from direct contact with moisture. This is crucial for preventing corrosion and ensuring the longevity of any prefabricated steel building foundation.

- Anchor Bolt Placement: Pedestals house the anchor bolts, providing the precise alignment and embedment depth required to securely bolt the steel column to the foundation.

Key Components of a Prefabricated Steel Building Foundation (Source: Internet)

3. Decision Framework for Choosing the Right Foundation for Steel Prefabricated Building

Selecting the optimal foundation for steel prefabricated building is a multi-variable engineering problem that requires a clear decision framework. The final choice maps a combination of site conditions, structural demands, and practical constraints to the most cost-effective and structurally sound solution.

|

Factor |

Key Considerations |

Impact on Foundation Choice |

|

Site/Soil Condition |

Soil Bearing Capacity (SBC), Water Table Depth, Consistency (Rock, Sand, Clay, Silt). | Determines the required depth and area of the footing. A soil with low bearing capacity or a high water table requires deep foundations or foundations with a large area, such as raft foundations or pile foundations. |

|

Building Loads |

Weight, Span, Crane Loads (dynamic/vibrational), Heavy Machinery. | High point loads or dynamic loads require stronger foundation systems, such as isolated footings with deep pedestals or pile foundations. |

|

Climate/Seismic Zone |

High Wind Speeds, Seismic Zone Rating, Local Hydrogeology. | High wind/seismic zones require robust tie beams, increased reinforcing, and detailed shear key design for lateral resistance. |

|

Budget/Schedule |

Cost of excavation, concrete, reinforcement, and labor; Time available for construction. | Shallow foundations (Isolated, Strip) are typically faster and cheaper than deep foundations (Pile). |

For Your Information: Modern Shed Workshop Designs for Industrial Applications

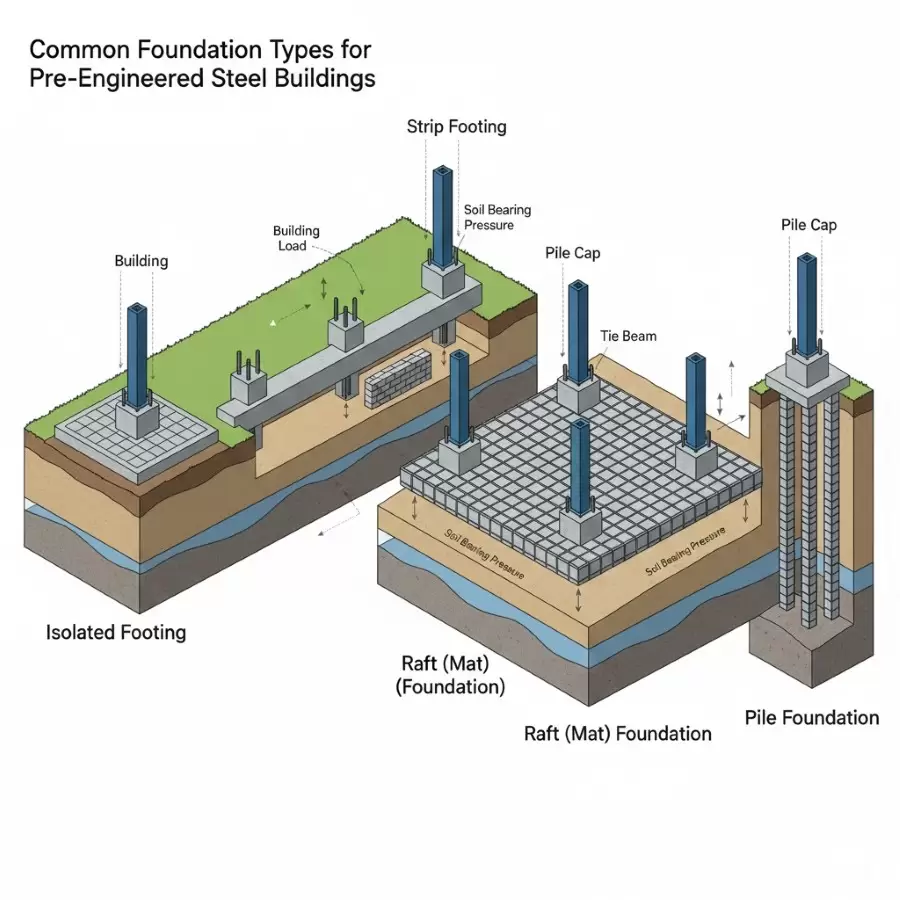

4. Common Foundation Types for Pre-Engineered Steel Buildings

Understanding the pros and cons of the most common types is key to making an informed decision about your foundation for steel prefabricated building.

Popular Foundation Types for Pre-Engineered Steel Buildings (Source: Internet)

4.1. Isolated Footing (Pad Footing)

Isolated footings are the most common and often the most economical choice for standard pre-manufactured steel buildings where the soil bearing capacity is adequate.

- Description: A square or rectangular pad of reinforced concrete placed directly beneath each structural steel column.

- Pros:

- Cost-Effective: Minimal excavation and concrete volume required.

- Simplicity: Easiest and fastest to construct.

- Versatile: Highly suitable for uniform soil conditions.

- Cons:

- Differential Settlement Risk: Susceptible to movement if the soil bearing capacity varies significantly between columns.

- Limited Load: Not ideal for extremely heavy loads or very poor soils.

- Sizing Cues: The required area AAA is determined by the column load PPP and the allowable soil bearing capacity qaq_aqa using the formula A=P/qaA = P / q_aA=P/qa.

4.2. Strip Footing (Continuous Footing)

Strip footings are essentially elongated isolated footings, designed to support a continuous line of load, such as an exterior wall or a series of closely spaced columns.

- Description: A continuous strip of concrete running under a structural or non-structural wall, or under an axis of columns where the columns are very closely spaced.

- Pros:

- Uniform Support: Distributes loads linearly, providing better support for perimeter walls than individual footings alone.

- Stability: Offers excellent resistance against lateral wall movement.

- Cons:

- More Material: Requires significantly more excavation and concrete than isolated footings.

- Suitability: Overkill for lightweight interior columns.

4.3. Raft (Mat) Foundation

A raft or mat foundation is a large, continuous slab that covers the entire footprint of the building, supporting all columns and walls.

- Description: A thick, heavily reinforced concrete slab that spreads the total building load over the entire area of the structure.

- Pros:

- Low Bearing Pressure: Ideal for sites with very low soil bearing capacity or highly compressible soils, as it minimizes the pressure on the ground.

- Differential Settlement Mitigation: Excellent at bridging over pockets of weaker soil, significantly reducing the risk of differential settlement across the structure.

- Cons:

- High Cost: Requires the largest volume of concrete and reinforcement steel.

- Complex Construction: Takes longer to build than shallow alternatives.

- Application: Often specified for large industrial facilities or in soft soil areas where Pebsteel might erect a multi-span warehouse or factory.

4.4. Pile Foundation

Pile foundations are classified as deep foundations and are used when the upper layers of soil are too weak to support the structure, requiring the load to be transferred to a deeper, stronger soil layer or rock.

- Description: Long, slender elements (concrete, steel, or timber) driven or drilled deep into the ground. A pile cap (a small footing) is placed on top of a group of piles to receive the steel column load.

- Pros:

- High Load Capacity: Essential for very heavy structures or buildings with large dynamic loads, such as those housing cranes or other heavy machinery.

- Poor Soil Solution: The best solution for sites with poor, expansive, or highly compressible near-surface soils, ensuring a stable prefab steel building foundation.

- Cons:

- Highest Cost & Time: Requires specialized equipment and is the slowest and most expensive option.

- Noise/Vibration: Driving piles can generate significant noise and vibration, which can be a concern in densely populated areas.

- Application: Critical for coastal projects or sites reclaimed from water, ensuring the stability of the prefabricated steel building foundation.

5. Notes When Building Foundations for Pre-Engineered Steel Buildings

Success in constructing a foundation for steel prefabricated building hinges on rigorous adherence to design specifications and best practices, particularly given the tight tolerances required to interface with the pre-manufactured steel frame.

Pebsteel always concentrates to note important considerations when constructing the foundation for pre-engineered steel buildings

5.1. Site Topography

The initial site evaluation dictates the foundation approach.

- Level Sites: Allow for the most economical shallow foundation solutions (Isolated/Strip).

- Sloped Sites: May require a “step footing” design to follow the slope or significant earthwork (cut and fill) to create a level building pad. The choice affects the volume of concrete and the overall stability.

- Water Table: A high water table necessitates dewatering during excavation, which increases costs and complicates the concrete curing process.

5.2. Materials

The quality of materials directly affects the foundation’s capacity and durability.

- Concrete Strength: Must meet the specified compressive strength to handle the column loads. Admixtures may be needed for fast setting or water resistance.

- Reinforcement Steel: Correct grade, size, and placement of rebar are crucial. Pebsteel and other reputable suppliers rely on the foundation contractor to use certified steel conforming to design specifications to manage stress concentrations at the column base.

5.3. Design

The foundation design must be seamlessly integrated with the superstructure design.

- Interaction: The structural engineer designs the steel frame and then transfers the resulting column reactions (vertical, shear, and moment) to the civil engineer, who designs the prefab steel building foundation to withstand them.

- Anchor Bolt Plans: The most critical component for a pre-manufactured steel buildings foundation is the anchor bolt layout. The location, projection, and orientation of these bolts must be precise, as the steel columns are manufactured with zero tolerance for misalignment. Deviations can delay erection and require expensive rework.

5.4. Construction

Accuracy during construction is paramount for this type of structure.

- Excavation: Must be precise, reaching the specified bearing stratum without disturbing the underlying soil.

- Formwork and Placement: The formwork for the pedestals and anchor bolts must be robust and accurately positioned to ensure proper placement. Techniques such as using rigid anchor bolt templates (often provided or specified by the steel fabricator, like Pebsteel) are essential to ensure the correct spacing and embedment before the concrete pour.

- Curing: Adequate curing time is necessary before the steel erection process begins to ensure the concrete reaches its required strength.

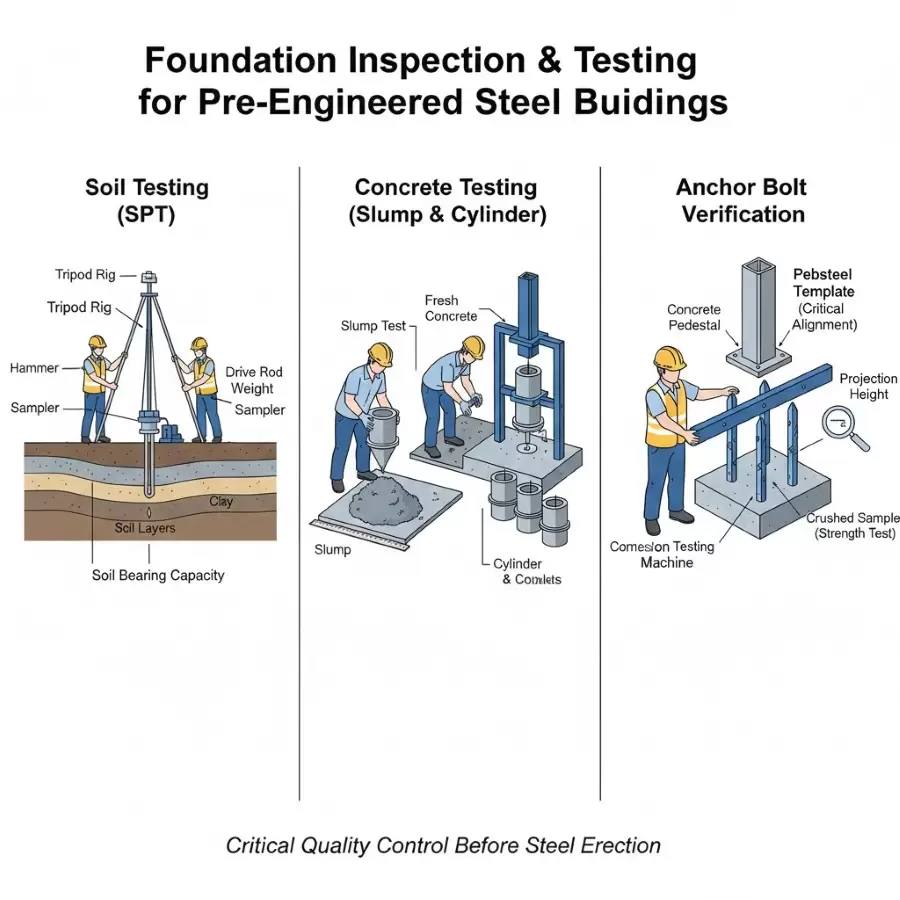

5.5. Inspection/Testing

Quality assurance is the final check before steel erection commences.

- Soil Testing: Compaction and bearing capacity tests, for example, the Standard Penetration Test, are performed before and after excavation to verify the design assumptions.

- Concrete Testing: Slump tests are performed during the pour, and cylinder breaks are conducted to confirm that the concrete reaches the specified compressive strength.

- Anchor Bolt Verification: A final inspection involves precisely measuring the anchor bolt projections and alignment. This is a crucial step before any steel from the supplier, whether it comes from a leading builder like Pebsteel, is shipped to the site. Failure to pass this inspection will result in significant schedule delays.

Final inspections, including soil, concrete, and anchor bolt tests, ensure the foundation meets all design requirements before steel erection (Source: Internet)

Final inspections, including soil, concrete, and anchor bolt tests, ensure the foundation meets all design requirements before steel erection (Source: Internet)

Choosing the right foundation for steel prefabricated building is not a matter of preference but an engineering requirement derived from a clear, systematic analysis.

The ultimate recommendation is always a balance:

- For excellent soil (high SBC) and standard loads, Isolated Footings with Tie Beams offer the best balance of cost and performance.

- For poor/variable soil conditions or heavy industrial loads (such as cranes), Raft or Pile Foundations are necessary to ensure the long-term stability and safety of the prefabricated steel building foundation.

By mapping the site’s geology and climate against the building’s structural demands and the project’s financial and time constraints, stakeholders can confidently select the foundation system that guarantees the stability and longevity of their pre-manufactured steel buildings. This critical decision ensures that the high-quality structure provided by steel construction specialists can stand robustly for decades to come.

To ensure the safety, stability, and cost-efficiency of your project, and to receive a foundation design perfectly integrated with your Pebsteel structure, please contact Pebsteel immediately via email at marketing@pebsteel.com.vn or by phone at (+84) 908 883 531 to receive consultation from our highly experienced engineering team.

Secure the success of your next pre-manufactured steel buildings project by starting with the right foundation strategy.

Disclaimer: The information provided in this article is intended for general reference and educational purposes only. Choosing the optimal foundation for steel prefabricated building requires a detailed geotechnical investigation (soil testing) and specific structural calculations tailored to your site’s unique conditions and the exact loads of the building. This information should not be used as a substitute for professional engineering design.