The construction of industrial warehouses requires careful investment, with the selection of building materials playing a crucial role. For any construction company Cambodia undertaking industrial projects, choosing the right materials not only affects durability and aesthetics but also directly impacts the construction and long-term operational costs of the warehouse. This article will provide you with useful information on the key factors to consider when selecting building materials for industrial warehouses, helping you make well-informed and optimized decisions for your construction project.

1. The Important Role of Choosing Suitable Construction Materials in Industrial Warehouse Construction

Choosing the right construction materials plays an extremely crucial role in industrial warehouse construction, directly affecting durability, efficiency, investment costs, and compliance with environmental standards, especially in large-scale shed fabrication projects.

- Reduced durability of the warehouse: Poor quality materials will not be able to withstand the load used and the impact of the environment, leading to rapid deterioration, cracks, and leaks, affecting production activities. business and even endanger people and property.

- Increased construction and operating costs: High-priced materials or unsuitable materials will lead to waste of initial construction costs and warehouse operating costs throughout the use process. For example, using poor insulation will increase electricity costs for the air conditioning system.

- Causes of environmental pollution: Warehouse construction materials may contain toxic substances, affecting human health and the environment. Using environmentally friendly materials with low toxic gas emissions will contribute to protecting the environment and minimizing negative impacts on the ecosystem.

- Reduce warehouse efficiency: Materials that are not suitable for use will affect the warehouse’s operational efficiency. For example, using poor fireproof materials will make the warehouse susceptible to fire and explosion, causing property damage during the warehouse construction process.

Therefore, the investor needs to take the time to thoroughly research and carefully consider the relevant factors in order to make the most prudent choice.

The Important Role of Choosing Suitable Construction Materials in Industrial Warehouse Construction

2. Important factors when choosing construction materials for industrial warehouses

2.1. Load capacity

Industrial warehouses are often used to store a variety of goods with different weights and sizes. Therefore, the building materials need to have the ability to withstand high load-bearing capacity, ensuring the safety of the warehouse structure and the stored goods. It is necessary to calculate the load factors such as the weight of the goods, rain load, wind load, and other loads in order to select materials with appropriate load-bearing strength.

2.2. Durability

Industrial warehouses often operate in harsh environments with impacts such as rain, wind, and storms. Therefore, the building materials need to have high durability and good resistance to these environmental conditions. At the same time, it is advisable to consider materials that can resist corrosion, waterproofing, termites, and fire to ensure the long-term lifespan of the warehouse.

2.3. Thermal insulation

Effective thermal insulation for warehouses helps regulate the indoor temperature, minimizing energy consumption for cooling or heating systems. It is advisable to select materials with a low thermal conductivity coefficient and combine them with a suitable insulation system to achieve optimal thermal efficiency.

2.4. Aesthetics

Constructing an industrial warehouse requires not only ensuring storage functionality, but also maintaining aesthetic compatibility with the overall architectural design of the area. It is possible to select building materials with diverse colors and patterns to create visual highlights for the warehouse.

2.5. Expense

Cost is a critical factor that must be carefully considered when selecting building materials for a warehouse. It is necessary to compare the unit prices of various materials, as well as calculate the costs of construction and maintenance, in order to identify the most economically optimal solution.

2.6. Construction ability

The choice of construction materials needs to ensure ease of construction and installation to save time and costs. It is advisable to choose materials with dimensions appropriate to design requirements (for example, steel structure design), and use appropriate accessories and construction methods.

2.7. Environmental friendliness

The selection of recyclable or renewable raw material-based ecologically friendly building materials should take precedence. Utilizing eco-friendly products helps businesses reduce their negative environmental effects.

2.8. Local requirements

Some localities may have regulations on the use of construction materials for industrial warehouses. It is necessary to carefully study these regulations to ensure material selection in accordance with local requirements.

Important factors to consider when choosing materials for industrial warehouses construction

3. Guidelines for selecting the right building materials for industrial warehouse construction based on intended uses

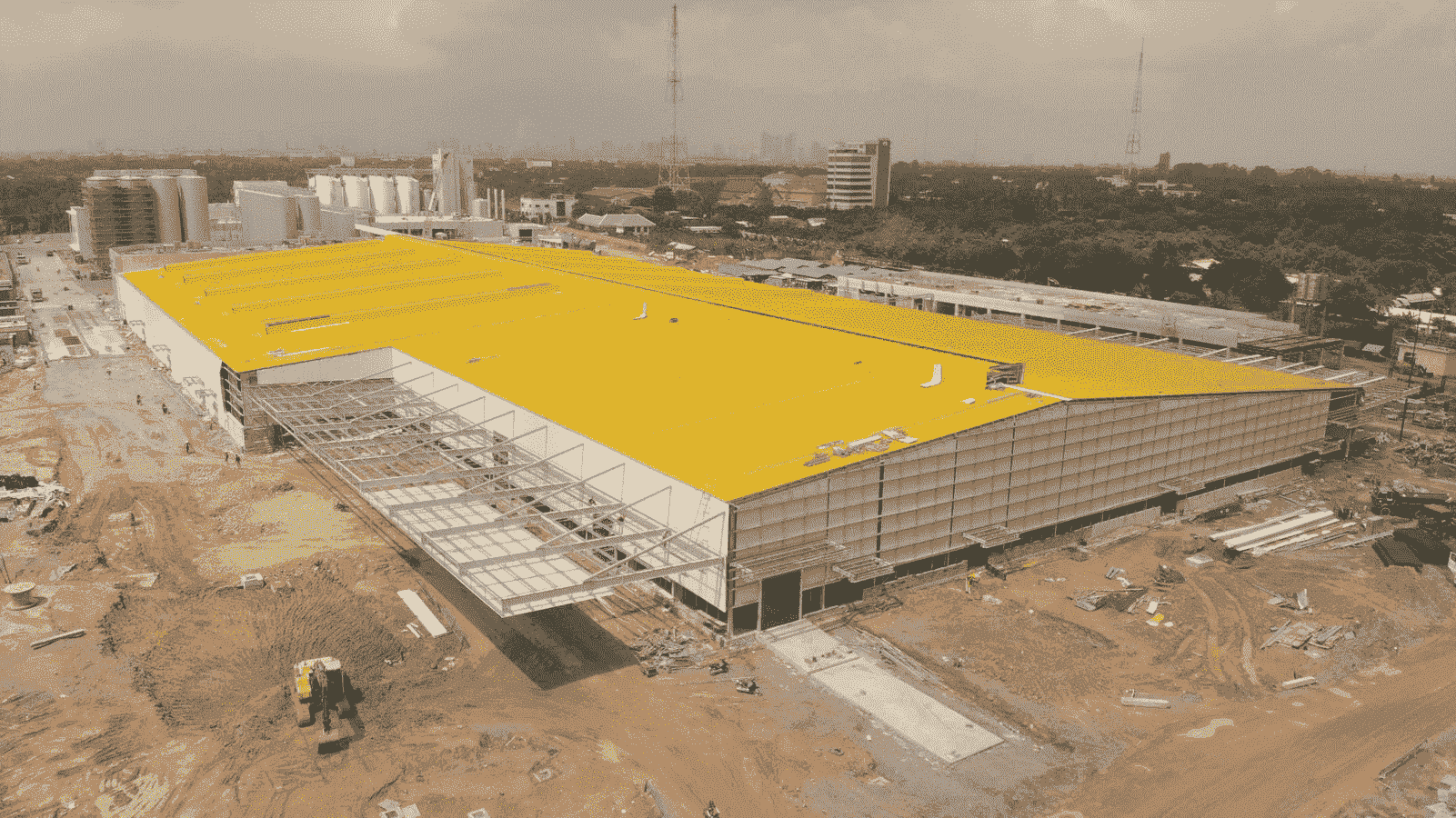

3.1. Prefabricated steel

Among the widely available materials today, prefabricated steel has emerged as the optimal solution, meeting the stringent demands of investors due to its superior advantages.

- It possesses a higher strength-to-weight ratio compared to traditional building materials such as concrete and wood.

- Prefabricated steel exhibits excellent resistance to corrosion and infestation, making it suitable for chemical storage facilities, metal warehouses, or coastal regions.

- The structural design of prefabricated steel is engineered for high durability, withstanding strong impacts and ensuring the safety of warehouses and stored goods.

- The high load-bearing capacity of prefabricated steel meets the requirements for constructing warehouses with wide spans and significant heights, accommodating diverse storage needs.

- It can be easily fabricated into various shapes and sizes, tailoring to the specific design requirements of warehouse projects.

- Prefabricated steel can be effectively combined with other materials, such as concrete and wood, creating a robust and durable warehouse structure. This allows for diverse roof and building frame designs, meeting both aesthetic and technical demands of each construction project.

In addition, the use of prefabricated steel in warehouse construction contributes to reducing construction waste and promoting sustainable construction development. Because they are 100% recyclable materials, contributing to environmental protection and saving resources.

3.2. I-shaped steel beam

I-shaped steel beams are made from high-strength steel, with a characteristic I-shaped cross-section, providing outstanding load-bearing capacity, meeting high requirements for durability and safety for warehouse roof structures:

- Strength: Large loads, such as the self-weight load of a roof, snow loads, wind loads, construction loads, and other dynamic loads, can be supported by Steel I-beam.

- High rigidity: Due to their large moment of inertia, I-shaped steel beams have high rigidity, resisting sagging and ensuring the stability and safety of the warehouse roof structure throughout its service life.

- Outstanding fire resistance: Steel has a high fire resistance, which helps steel I-beams reduce the chance of collapsing in the event of a fire and safeguards the security of the people and goods inside the warehouse.

- Cost-saving: Because steel I-beams can cover wide distances, fewer support columns are needed, which lowers construction costs and maximizes the amount of space that can be used inside the warehouse.

- Rapid installation: The manufacturing and installation processes for I-shaped steel beams have been optimized, ensuring high precision, which helps to shorten the construction time, save labor costs, and accelerate the construction schedule.

3.3. Fiberglass struts

Fiberglass struts are made of microscopic glass fibers, tightly bonded together, creating outstanding durability, and withstanding high loads, not inferior to steel. Thanks to its fibrous structure, fiberglass struts have a much lighter weight than steel, minimizing the load on the project and saving transportation and installation costs.

- Unlike electrically conductive steel, fiberglass reinforced polymer (FRP) purlins have excellent insulating properties, eliminating the risk of short circuits and fires due to electrical discharge, ensuring optimal safety for the warehouse.

- The high fire resistance of fiberglass helps effectively prevent the spread of flames, protecting the stored goods and assets from fire hazards.

- Immune to rust and corrosion, FRP purlins are not affected by the impact of chemicals or harsh environments, ensuring long-term durability.

- The excellent water resistance helps protect the warehouse structure from leaks, moisture, and mold, maintaining an ideal storage environment for the goods.

Additionally, because fiberglass has unique qualities, the process of building and installing fiberglass struts calls for advanced technology and expert knowledge. The struts’ efficacy and safety may be impacted by improper building methods. Strong impacts can cause fiberglass struts to fracture or lose some of their durability because of their fibrous structure.

3.4. Concrete

Besides steel, concrete plays the role of foundation-building material for industrial warehouse projects, bringing many outstanding advantages to meet strict requirements for durability, safety, and economic efficiency.

- Possessing high compressive strength, FRP is ideal for constructing warehouse framing, able to withstand the heavy loads from the roof system, equipment, and stored goods.

- The excellent flexural strength allows the construction of warehouses with wide spans, meeting diverse storage needs without the need for many support columns, optimizing the usable space.

- The high thermal resistance helps the warehouse structure remain robust against fire impacts, minimizing the risk of collapse and deformation.

- The resistance to corrosion from chemicals, acids, and seawater makes it suitable for warehouses storing chemicals, metal products, or in coastal areas.

- The outstanding water resistance helps protect the warehouse structure from the impact of rainwater and moisture, maintaining an ideal storage environment for the goods

Concrete can be cast on-site or use precast concrete panels, suitable for many different sizes and styles of warehouses. Flexibility in construction allows for diverse structural shapes, meeting the aesthetic needs and technical requirements of each project.

3.5. Brick

Brick walls are built from solid bricks or block bricks with high strength, can withstand large loads, and ensure the safety of the warehouse structure. The cost of building brick walls is relatively reasonable compared to other materials such as steel and concrete because of its outstanding advantages:

- Ability to effectively withstand storms and heavy rains, suitable for areas with harsh weather conditions and frequent natural disasters.

- High durability, less likely to break or crack, no warping over time, ensuring safety for goods stored inside.

- Long lifespan, little maintenance required, saving operating and maintenance costs for the warehouse throughout its life.

- Brick walls do not require painting or other surface protection measures, minimizing routine maintenance costs.

The surface of brick walls can be finished in various ways, such as painting, tiling, or creating aesthetic accents, enhancing the overall visual appeal of the structure. Brick walls contribute to the regulation of indoor temperature within warehouses, creating an ideal storage environment for goods.

3.6. Aluminum

The aluminum frame is made from aluminum alloy with a high strength/weight ratio, helping to reduce the load on the foundation and warehouse structure.

Aluminum bars are manufactured using a modern, high-precision process, ensuring uniformity and ease of assembly. They are effective against rust and corrosion and suitable for warehouses storing chemicals, metal materials, or coastal areas.

Construction of aluminum frames takes place quickly, saving time and costs compared to traditional construction methods. Because of the ability to easily disassemble, move, and change size, it is suitable for flexible use needs of the warehouse.

3.7. Bitumen roofing sheets for warehouse roofs

Bitumen roofing sheets are made of many layers of materials such as fiberglass, paper, and asphalt, providing high durability, high load resistance, good impact resistance, and other outstanding features such as:

- Effective waterproofing ability protects the roof structure from the impact of heavy rain, snow, and salt frost.

- Good heat resistance, fire resistance, minimizing the risk of fire for warehouses and UV rays resistance, anti-aging, and long-lasting color retention over time.

The cost of bitumen roofing sheets is relatively inexpensive compared to other roofing materials such as tiles and metal sheets. This is because they are quick and easy to install, save on labor costs, require little maintenance and repair, have a long lifespan, and provide long-term economic benefits for the investor.

Selecting the right building materials for an industrial warehouse is a process that requires careful consideration based on many factors. Hoping that the information shared in this article has provided you with more knowledge and greater confidence in selecting the right building materials for your warehouse project. Remember to consult with experienced construction experts and reputable suppliers to get the most optimal solution for your needs.

For comprehensive solutions in warehouse construction, please contact Pebsteel via email at marketing@pebsteel.com.vn or hotline at (+84) 908 883 531 for immediate assistance!

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.