In the dynamic logistics industry, the selection of warehouses plays a pivotal role, directly impacting costs, transportation speed, and the quality of goods. This article will provide a detailed introduction to the common types of warehouses in the logistics field, helping you make a well-informed decision for your business:

1. Definition and important role of warehouse in logistics and supply chain management

1.1. Definition

Warehouses, also known as storage facilities, are specialized infrastructure designed and constructed to store, preserve, and manage goods. Warehouses play a central role in the logistics and supply chain management field, ensuring the seamless and efficient flow of goods from the manufacturer to the consumer.

1.2. Role

Warehouses are the focal point of supply chain management, acting as the core for storage and distribution activities. They are also systematically organized spaces where goods are maintained and preserved:

- Providing storage space: Warehouses provide an area to store goods safely and scientifically, ensuring the quality and value of products are preserved intact.

- Classification of goods: Goods are classified by type, size, value,… for easy management, inventory, and import and export.

- Goods arrangement: Goods are arranged scientifically on shelves, pallets, or racks to optimize storage space and facilitate access.

- Storage of goods: The warehouse is equipped with appropriate storage conditions for each type of goods, ensuring that goods are stored in an environment of appropriate temperature, humidity, and ventilation, avoiding damage and wear.

- Track the quantity of goods: A modern warehouse management system helps track the quantity of goods imported, exported, and in stock accurately and promptly. Information about the status, quality, and expiration date of goods is continuously updated to ensure that goods are used effectively and on time.

- Prepare inventory reports: Inventory reports provide detailed information about the quantity, value, and status of inventory goods, helping businesses make decisions to adjust production plans and purchase goods. rationalize.

- Prepare goods and deliver: Goods are packaged, labeled, and quality-checked before being shipped to ensure they meet customer requirements. Goods are transported from the warehouse to customers quickly, safely, and efficiently.

- Reverse logistics: Goods that are defective, damaged, or do not meet customer requirements are returned to the warehouse for processing. Returned goods are inspected, sorted, and handled according to established protocols.

- Minimize storage costs: Using warehouses properly helps minimize storage costs such as warehouse rental costs, goods preservation, labor, etc. Warehouses help ensure the smooth flow of goods. streamline the supply chain, reduce delivery times, and improve operational efficiency.

Effective warehouse management helps businesses improve service quality, better meet customer needs, and improve competitiveness in the market.

Definition and important roles of warehouses

See more: Warehouse Construction Process

2. Common types of warehouses in logistics

2.1. Tax suspension warehouse

Definition and role

Bonded warehouses are facilities authorized by customs authorities where enterprises can store and preserve imported raw materials and goods that have already been cleared through customs but have not yet paid import duties. These bonded warehouses play a crucial role in import-export operations, providing numerous benefits to businesses:

- Reduce storage costs: Businesses do not need to pay import tax before storing, helping to reduce the financial burden.

- Increase flexibility: Businesses can import raw materials and goods before having export orders, be proactive in production, and promptly respond to market needs.

- Optimize capital flow: Enterprises use capital to invest in production instead of paying import taxes, helping to increase capital use efficiency.

- Shorten delivery time: Businesses can produce and export goods more quickly because they do not have to wait for customs clearance to import raw materials.

- Facilitates re-exports: Bonded warehouses simplify the procedures for re-exporting goods.

Regulations on the establishment and operation of tax suspension warehouses

Establishment requirements: Enterprises must meet certain conditions in terms of financial capacity, reputation, import-export experience, physical infrastructure, equipment, warehouse management systems, and other requirements stipulated by law.

Establishment procedures: Enterprises must submit an application to establish a bonded warehouse to the customs authorities, in accordance with the regulations.

Operations: Enterprises must carry out obligations such as declaring, reporting, inspecting, and monitoring the activities of the bonded warehouse according to the provisions of the law.

2.2. Inland warehouse

Situated deep within the mainland, inland warehouses are convenient for road and rail transportation. Inland warehouses have lower transportation costs, making them suitable for bulky and heavy goods. However, the construction of these warehouses is typically far from seaports, which poses challenges for the import and export of goods.

2.3. Coastal warehouse

Located near seaports, coastal warehouses are convenient for maritime transportation. The construction of coastal warehouses facilitates easier import and export activities, saving time on transportation. However, the transportation costs are higher compared to inland warehouses.

2.4. Border warehouse

Located near national borders, border warehouses are convenient for the transportation of goods across borders. Border warehouses offer the benefit of saving time and transportation costs for imported/exported goods crossing the border. However, the customs procedures at border warehouses tend to be more complex compared to coastal warehouses.

2.5. Transit warehouse

Important function

Cargo consolidation points: These are facilities where goods from various sources are aggregated prior to being sorted, organized, and then transported to the next destination point.

Sorting and deconsolidation centers: Goods are classified by the shipper, type, size, destination, etc. to optimize transportation.

Delivery gates`: Where goods transfer activities take place between suppliers, carriers, and customers.

The bottleneck in the supply chain: Transit warehouses help connect links in the supply chain, ensuring smooth and efficient circulation of goods.

Outstanding features

Short storage time: Goods at transit warehouses are only stored for a short time, usually from a few days to a few months, and there are even cases where “imported and immediately exported”.

High flexibility: Transit warehouses can meet diverse storage needs, from retail goods, and full containers to oversized and overloaded goods.

Strategic locations: Transit warehouses are often located in convenient traffic locations, near seaports, airports, industrial parks, logistics centers, etc.

Advanced management system: Applying an advanced warehouse management system, helping to track the location, quantity, and status of goods accurately and effectively.

Realistic benefit

Optimizing transportation, minimizing storage costs, reducing empty transportation costs, etc. Increasing the speed of goods circulation, shortening delivery times, and quickly meeting market demands.

At the same time, helping businesses improve operational efficiency, reduce product costs, and enhance competitiveness in the market.

Practical application

Imported goods: After customs clearance, goods are gathered at the transit warehouse before being transported to distributors and retail agents.

Exported goods: Goods are transported from the manufacturing plant to the transit warehouse for gathering, containerization, and transportation to the export port.

Domestic goods: Goods are transported from manufacturers to transit warehouses for distribution to different areas within the country.

Transit warehouse in logistic service

2.6. Cold storage warehouse

Storing food, pharmaceuticals, and chemicals requires special temperature storage conditions. They ensure the quality of goods under optimal storage conditions but incurs high investment and operating costs.

Storing food, pharmaceuticals, and chemicals requires special temperature storage conditions

2.7. Automated warehouse

An automated warehouse utilizes an automation system to control and manage goods. They enhance operational efficiency and minimize labor costs, but require a significant investment and careful consideration before implementation.

2.8. Public warehouse

Public warehouse is a type of warehouse owned and managed by professional warehouse service providers. Unlike private warehouses that are used by a single business entity, public warehouses provide storage services for multiple different customers.

Public warehouses play a vital part in logistics activities, providing the different commodities storage demands of firms, especially:

- Newly established businesses: Newly established businesses often have limited capital and are not qualified to build their warehouses. Public warehouses help businesses store goods at reasonable costs in the early stages of operation.

- Businesses with short-term storage needs: Businesses can use public warehouses to store seasonal goods, project goods, or goods that need to be transferred in a short time.

- Businesses that want to expand the market: Businesses can rent public warehouses in new areas to store goods and serve the needs of customers in that area.

Public warehouse for logistic services

2.9. Private warehouse

Enterprises build and manage their warehouses to serve their own goods storage needs to save costs and control warehouse operations well. However, they will cause high investment costs and difficulty in scaling.

2.10. Temperature-controlled warehouse

Definition and role

A temperature-controlled warehouse (also known as a cold storage or cool storage warehouse) is a type of warehouse designed and equipped with a modern system to regulate temperature, humidity, and airflow to preserve goods under optimal environmental conditions. As a result, the quality of goods is maintained, minimizing damage and deterioration caused by temperature and humidity fluctuations.

Temperature-controlled warehouses play an extremely important role in preserving items that are particularly sensitive to the environment such as:

- Food: Meat, fish, vegetables, fruit, milk, eggs, etc.

- Frozen foods: Ice cream, ice cream cups, frozen meat, frozen seafood, etc.

- Seafood: Fresh fish, shrimp, squid, crab, crab, etc.

- Pharmaceuticals: Vaccines, drugs, medical materials, etc.

- Chemicals: Volatile chemicals, dangerous chemicals, etc.

Outstanding features

Temperature control system: The warehouse is equipped with a modern refrigeration and heating system to adjust the temperature according to the specific requirements of each type of goods.

Humidity control system: The warehouse has a system for dehumidification and humidification to maintain the appropriate humidity level, preventing goods from becoming dry, cracked, or moldy.

Ventilation system: The ventilation system ensures proper airflow within the warehouse, removes CO2 and harmful gases, and provides oxygen for the goods.

Construction materials: Carefully selected construction materials ensure good insulation and waterproofing properties, helping to maintain stable temperature and humidity levels.

Sensors and monitoring system: Sensor and monitoring systems continuously monitor the temperature and humidity inside the warehouse, providing alerts when any changes exceed the permissible thresholds.

2.11. E-commerce warehouse

An e-commerce warehouse (also known as an order fulfillment center) is a warehouse facility operated by third-party logistics (3PL) companies. It plays a crucial role in order processing, which includes:

- Receive goods: Receive goods from the seller, check quantity, and quality, and store according to procedures.

- Storage: Store goods in appropriate conditions, ensuring safety and integrity.

- Selecting goods: When there is an order, warehouse staff will select goods according to order information, ensuring the accuracy and completeness of products.

- Packaging: Pack goods carefully to ensure safety during transportation.

- Shipping: Deliver goods to customers through reputable shipping services.

E-commerce warehouse for logistic services

2.12. Container freight station warehouse (CFS)

A Container Freight Station (CFS), also known as a consolidation point, plays a crucial role in the supply chain, especially for less than container load (LCL) shipments. It is a facility where cargo from multiple shippers is gathered, sorted, packaged, and consolidated before being loaded into shared containers for transportation.

As a hub for products transshipment, the CFS warehouse assists:

- Lower shipping costs: Rather than sending out individual tiny shipments, businesses can save money on shipping by merging the items of multiple shippers into a single container.

- Boost shipping effectiveness: The shared use of containers optimizes the utilization of container space, minimizes waste, and increases the efficiency of transportation.

- Simplify procedures: Businesses can save time and effort by completing customs procedures only once for a common container, rather than having to do them for every tiny shipment.

- Increase flexibility: CFS warehouse offers adaptable services to suit a range of client requirements, including labeling, packaging, printing invoices, and organizing items as needed.

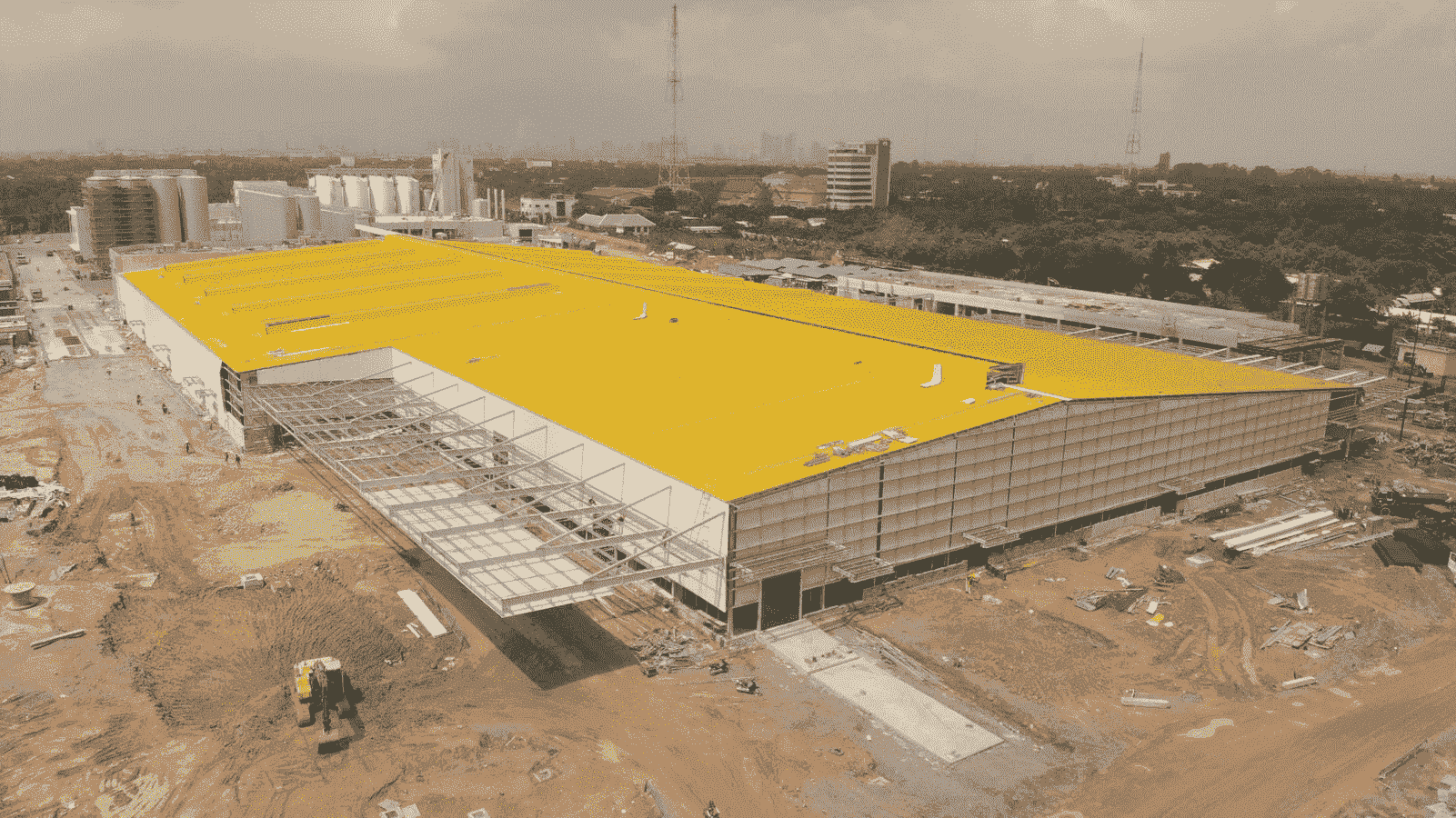

3. Important notes when building a warehouse for logistics

Building a warehouse for logistics requires careful consideration and compliance with many criteria to ensure efficiency, safety, and cost savings. Here are some important notes to keep in mind:

3.1. Determine the demand and purpose of use

Sort of goods stored: Select the right building supplies and storage systems by first determining what kind of items (dry goods, frozen goods, chemicals, etc) will be kept in the warehouse.

Storage scale and capacity: To build a functional warehouse space and products management system, ascertain the volume and amount of goods that must be stored.

Automation Level: Organize buildings and equipment according to the required level of automation during warehouse operations (using automatic forklifts, WMS warehouse management system, etc)

3.2. Select construction location

Convenient transportation: The warehouse location needs to be convenient for transporting goods by road, waterway, and air, ensuring connection with main traffic routes and industrial parks, seaports, and airports.

Adequate technical infrastructure: The warehouse construction area needs to have stable electricity, water, and internet systems to meet the operational needs of the warehouse.

Human resources: Ensure abundant human resources with appropriate professional qualifications for warehouse operations.

Expand area: Choose a location with the ability to expand the area in the future to meet the development needs of the business.

3.3. Design and construction

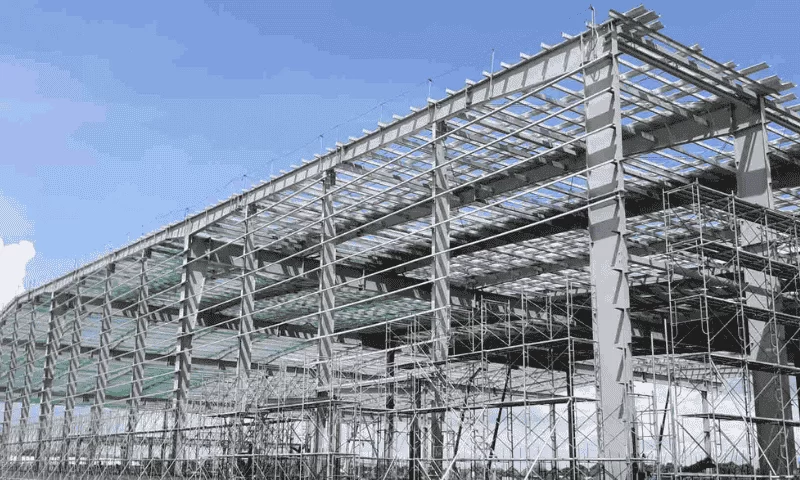

Solid structure: Use steel structures, reinforced concrete, or other structures when building a suitable warehouse to ensure safety and load-bearing capacity, especially when storing heavy or bulky goods. Pre-engineered steel buildings usually use steel structure design to shape the structure and calculate conditions before construction.

Roofs and partitions: When constructing warehouses, choose materials that are waterproof and well-insulated to protect items from the elements and maintain the right humidity and temperature levels.

Door system: Install a door system and ventilation door of appropriate size, ensuring safety and convenience for transporting goods.

Electrical and water systems: Design electrical and water systems to ensure adequate capacity for operating equipment, lighting systems, and fire protection systems and meet the daily needs of employees throughout the warehouse construction and use process.

Fire fighting and prevention system: Install a modern fire protection system, ensuring safety for people and assets in the warehouse.

Security system: Equipped with the surveillance camera system and burglar alarm system to ensure warehouse security.

3.4. Material selection

Highly durable materials: Utilize materials with high durability, capable of withstanding heavy loads, resistant to moisture and pests, to ensure the long-term lifespan of the facility.

Environmentally friendly materials: Prioritize the use of environmentally-friendly materials that are energy-efficient and minimize negative environmental impact.

Climate-Appropriate Materials: Select materials that are well-suited to the local climatic conditions of the warehouse location to ensure effective performance and cost-efficient maintenance.

3.5 The method of scientific management

Implement a warehouse management system: Track and efficiently manage the location, amount, and condition of commodities in different kinds of warehouses by utilizing a warehouse management system.

Professional employee training: Provide comprehensive training to employees on warehouse operations processes, occupational safety, and the proper use of equipment and machinery across various warehouse types.

Scheduled preventive maintenance: Implement a comprehensive preventive maintenance program for the warehouse’s systems, equipment, and structural components to ensure continued safety and optimal performance after the warehouse construction is complete.

Important considerations when constructing warehouses for logistics operations

Warehouses play a pivotal role in logistics and supply chain management. There are various warehouse models, each with its own unique advantages and disadvantages. Businesses need to carefully select the warehouse type that best suits their specific needs and business operations to optimize the benefits that warehousing can provide.

For comprehensive solutions in warehouse construction, please contact Pebsteel via email at marketing@pebsteel.com.vn or hotline at (+84) 908 883 531 for immediate assistance!

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.