In today’s evolving industrial construction landscape, businesses need spaces that are robust yet adaptable, and a modern shed workshop perfectly meets this demand with its durability, flexibility, and operational efficiency. Far from the image of a small backyard shed, an industrial shed workshop is a sophisticated pre-engineered steel building designed to accommodate manufacturing lines, logistics centers, and heavy machinery.

As speed and quality become paramount, more investors are moving away from traditional reinforced concrete and turning to agile steel structures that enable vast, column-free interiors. This article explores the anatomy of the modern industrial shed workshop, its advantages over conventional construction, and its crucial role across sectors such as metal fabrication, automotive maintenance, and broader industrial operations.

1. What is an Industrial Shed Workshop?

In the modern context, a shed workshop is a steel-structured facility characterized by a simple yet structurally sound design. While the terminology suggests simplicity, the engineering behind these structures is advanced. Unlike traditional workshops built with brick and mortar, a steel shed differs significantly in terms of cost, construction time, and adaptability.

Historically, factories were heavy and rigid structures. Today, the steel building dominates the industrial sector. The core difference lies in the fabrication process. A steel shed is manufactured off-site to exact specifications and assembled on-site. This method is known as pre-engineered building and allows for a level of precision that on-site concrete casting simply cannot match.

For medium- to large-scale industrial applications, the structural integrity provided by rigid frames enables wide spans without internal columns. This is crucial for workshops that require unhindered movement of forklifts, cranes, and large assembly components. Systems like those engineered by Pebsteel, a leading steel structure fabricator in Vietnam, utilize high-tensile steel to ensure that the building is lighter than concrete equivalents while maintaining superior load-bearing capacities.

For Your Information: Why Steel Shed is the Best Choice for Long-Lasting Storage Solutions

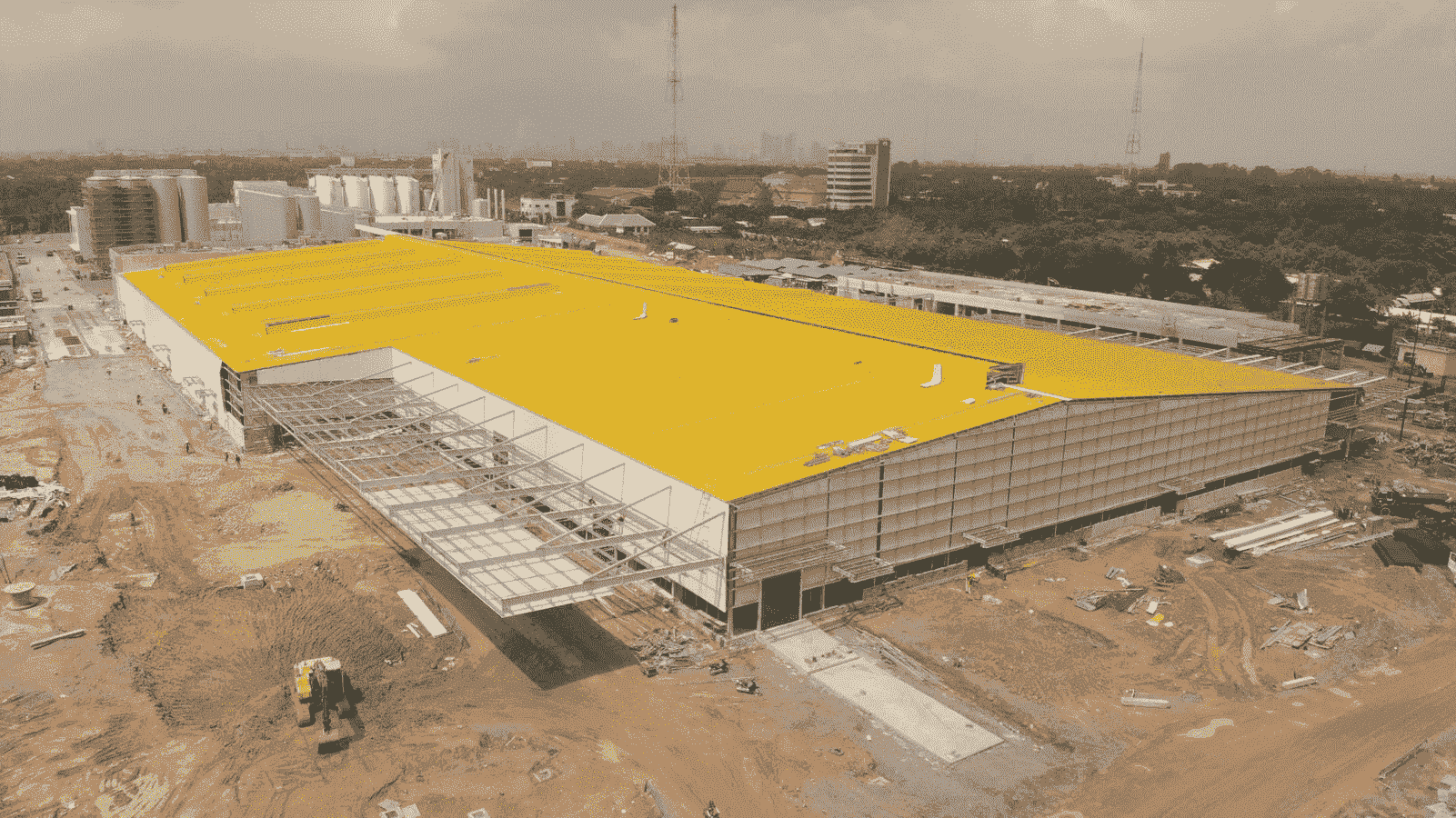

Introducing the Modern Industrial Shed Workshop

2. Key Features of High-Quality Steel Sheds

The popularity of the shed workshop is not a trend but a strategic choice based on tangible benefits. Key features include high durability, expandability, cost-effectiveness, quick construction, and eco-friendliness.

2.1. Unmatched Durability

Industrial environments are harsh. Structures must withstand vibrations from heavy machinery, corrosive elements, and extreme weather conditions. A well-engineered steel structure offers exceptional resistance to these factors. High-grade steel components are often treated with galvalume or specialized coatings to prevent rust and corrosion. This treatment significantly extends the lifespan of the facility.

2.2. Flexibility and Expandability

One of the most significant advantages of shed fabrication using steel is modularity. As a business grows, its physical space must expand in tandem. Traditional buildings are difficult and expensive to expand. Conversely, a steel shed workshop is designed with future expansion in mind. Additional bays can be added to the existing frame with minimal disruption to ongoing operations. This feature is often prioritized in designs by industry leaders like Pebsteel.

2.3. Cost-Effectiveness

Cost efficiency involves more than just the initial price tag. It encompasses the Total Cost of Ownership (TCO). Steel buildings reduce foundation costs because they are lighter than concrete structures. Furthermore, the precision of shed fabrication reduces waste and labor costs on-site. The maintenance requirements for a steel shed are also significantly lower over the building’s lifecycle.

2.4. Rapid Construction

Time is money in the industrial sector. A pre-engineered steel building can be erected in a fraction of the time required for conventional construction. Since the components are cut, drilled, and welded at the factory, the on-site process is strictly assembly. This allows businesses to become operational and start generating revenue months sooner than they would with traditional methods.

2.5. Eco-Friendliness and Sustainability

Modern industry places a high premium on sustainability. Steel is one of the most recyclable materials on the planet. A steel shed is not only built from materials that often contain recycled content, but the structure itself is 100% recyclable at the end of its life. Additionally, steel structures can be insulated effectively to reduce energy consumption for heating and cooling.

3. Common Industrial Applications of Shed Workshops

While the term “shed” can be ambiguous, in the professional sector, shed workshops are widely used in industries such as manufacturing, metal fabrication, storage & logistics, and automotive garages. These are not small-scale residential projects, but rather medium- to large-scale industrial facilities designed for heavy-duty operations.

3.1.Manufacturing Plants Utilizing Steel Structures

For manufacturing sectors, the layout is critical. A shed workshop provides the open floor plan necessary for assembly lines. The inherent strength of a steel structure enables the installation of overhead cranes, which are often capable of lifting up to 10 or 20 tons. These cranes are crucial for moving heavy goods across the production floor. The integration of crane beams into the structural frame is a standard capability of high-end providers such as Pebsteel.

Manufacturing Plants Utilizing Steel Structures

3.2. Heavy Metal and Shed Fabrication Facilities

Businesses involved in shed fabrication or heavy metalworks require environments that are fire-resistant and well-ventilated. Steel structures are inherently non-combustible, providing a safer environment for welding and cutting operations. The high ceilings associated with these designs help dissipate heat and fumes, ensuring a safer workspace for employees who operate in these intense conditions.

3.3. Logistics Warehouses and Steel Sheds

The rise of e-commerce has spiked the demand for warehousing. A steel shed optimized for logistics maximizes vertical storage space. The clear-span design allows every square meter of floor space to be utilized for racking systems and forklift maneuvering paths because there are no internal support columns to obstruct the workflow.

Steel Shed Solutions for Modern Logistics Warehouses

3.4. Automotive Garages and Steel Building Systems

We are not referring to a single-car garage but rather large-scale fleet maintenance facilities. Transport companies and mining operations require massive workshops to service trucks and excavators. These facilities need large bay widths and high eave heights. These specific architectural features are easily achievable with a pre-engineered steel building system.

4. Modern Trends in Shed Workshop Design

The design of industrial spaces is evolving. It is no longer enough to simply have four walls and a roof. Current trends focus on open layouts, natural lighting and ventilation, the use of BIM technology, and sustainable materials.

4.1. Open Layouts and Clear Spans

The “Clear Span” capability is the hallmark of modern structural steel design. By eliminating interior columns, businesses gain complete flexibility in configuring their internal operations. This enables the reconfiguration of production lines without imposing structural constraints.

4.2. Natural Lighting and Ventilation

Energy efficiency is a major driver in modern design. Industrial sheds are increasingly incorporating translucent skylights and wall lights to utilize natural daylight, thereby reducing their reliance on artificial lighting. Furthermore, ventilation systems, such as roof monitors and ridge vents, are integrated directly into the steel shed design to ensure optimal air circulation. Pebsteel and similar manufacturers often incorporate these accessories as integral parts of the primary structure to ensure weather tightness.

Natural Lighting and Ventilation

4.3. BIM Technology (Building Information Modeling)

The era of 2D drafting is coming to an end. Shed fabrication is now driven by BIM technology. This involves creating a digital twin of the workshop before a single piece of steel is cut. BIM allows engineers to detect clashes, optimize material usage, and visualize the integration of mechanical, electrical, and plumbing (MEP) systems. This technological approach ensures that the final steel building is erected with zero errors.

4.4. Sustainable Materials and Insulation

To combat heat gain, especially in tropical climates, modern workshops utilize sandwich panels with high-grade insulation for roofs and walls. Examples include PU or Rockwool insulation. This not only improves the comfort of the workforce but also protects sensitive machinery and goods from temperature fluctuations.

5. Overview of Small-scaled Shed Workshop

Building on the proven efficiency of modern industrial factory design, steel structures have demonstrated strong performance in terms of load-bearing capacity, spatial optimization, and construction speed. Based on these established principles, small-scale shed workshops are developed with a more compact and simplified structural system, while still maintaining essential technical standards for safety, durability, and functionality. These structures offer a practical solution for small production, storage, and operational needs.

5.1. Benefits of Small-scaled Shed Workshop

Efficient Use of Space: Small-scaled shed workshops provide a dedicated area for storage, light production, or maintenance activities. By separating tools, equipment, and materials from other spaces, these sheds help keep operations organized and improve overall space utilization.

Durable and Practical Structure: With a simplified steel structure, small shed workshops offer reliable durability while remaining easy to maintain and adapt internally. Their compact design supports long-term use without complex structural requirements.

Dedicated and Focused Workspace: A small shed workshop creates a separate working environment that allows users to arrange equipment and workflows efficiently. This dedicated space helps improve productivity and ensures smoother daily operations.

Improved Privacy and Reduced Disturbances: By moving work activities into a standalone shed workshop, noise, dust, and operational clutter can be better controlled. This separation minimizes distractions and supports a more stable working environment.

Added Functional Value: Beyond daily use, a well-planned small-scaled shed workshop enhances the functional value of the property. It supports flexible usage and can be adapted over time as operational needs change.

Flexible Design Options: Small shed workshops can be customized in size, layout, and materials to suit specific site conditions and usage requirements, making them a practical solution for various small-scale applications.

5.2. Key Features of Small-scaled Shed Workshop

The overall characteristics of a shed workshop are not fundamentally different from those of conventional industrial warehouses. However, due to its smaller scale, a shed workshop offers several practical advantages compared to larger industrial facilities.

- Workspace and storage: The shed workshop is designed to serve both production and storage purposes at a small to medium scale, ensuring efficient use of internal space.

- Size and layout: The floor area is larger than a standard room (approximately 3 m × 2.5 m), providing sufficient space for operational activities and material storage.

- Electrical and utility systems: Electrical capacity is planned to support basic production and storage needs, in compliance with pre-engineered steel building standards. Temperature and humidity control should be considered depending on the stored goods.

- Internal arrangement: Working zones and storage areas should be clearly separated, with adequate circulation space to facilitate material handling.

- Thermal insulation and waterproofing: Proper insulation and waterproofing systems are essential to maintain suitable indoor conditions and protect goods from environmental impacts.

5.3. Applications of Small-scaled Shed Workshop

Owing to their distinctive characteristics and practical advantages, small-scale shed workshops have been widely adopted in various forms across different fields.

Woodworking or furniture production workshops are typical examples, where the same space is used for both manufacturing and product storage. This integrated layout brings significant benefits, as users do not need to invest in separate facilities while still meeting functional and operational requirements.

Small-scale workshop for wood production and storage (Source: Internet)

In addition, DIY shed workshops or handicraft production sheds are also common types of small-scale shed workshops. These structures are usually designed with simple structural systems, flexible layouts, and a high level of customization. They are well suited for light fabrication, artisanal production, or individual creative activities that require an independent workspace without the need for large-scale facilities.

DIY shed workshops (Source: Internet)

**Note: The content of this article is presented in a neutral manner and is intended solely to provide useful and informative insights to readers. It does not imply or state that Pebsteel undertakes the design, fabrication, or construction of small-scaled steel sheds or warehouses.

6. Critical Factors for Planning Your Project

Investing in an industrial facility is a significant commitment. Important factors include project scale and requirements, site location, material quality, and choosing a reliable contractor.

- Project Scale and Requirements

- Site Location and Environmental Loads

- Material Quality

- Choosing a Reliable Contractor

Whether planning a heavy manufacturing plant or a sophisticated logistics hub, the selection of a pre-engineered steel building system ensures that the investment remains secure against the elements and adaptable to market changes. With industry leaders like Pebsteel setting the benchmark for quality and innovation, the modern industrial shed stands as a testament to the power of steel in contemporary architecture.

Please contact Pebsteel immediately via email at marketing@pebsteel.com.vn or by phone at (+84) 908 883 531 to receive consultation from our highly experienced engineering team.

Note: The content provided above is for reference purposes only. For further details or clarification based on your needs, please contact Pebsteel directly.