Given their unique characteristics, prefabricated building walls require special construction materials. These requirements aim to create durable, beautiful, and sturdy prefabricated buildings. Join Pebsteel to explore the specialized materials commonly used for prefabricated building walls today.

1. What is a Prefabricated Steel Building?

Prefabricated steel buildings are constructed using structural steel components that are manufactured and assembled according to standardized processes. Elements such as columns, beams, purlins, walls, and roofs are pre-fabricated in the factory based on technical designs, then transported to the construction site for assembly.

Thanks to this process, constructing prefabricated steel buildings is quick, saving both time and costs compared to traditonal construction methods. However, to ensure long-term stability and performance, prefabricated steel buildings must be supported by a well-engineered foundation for steel prefabricated building that matches the structural design and load requirements.

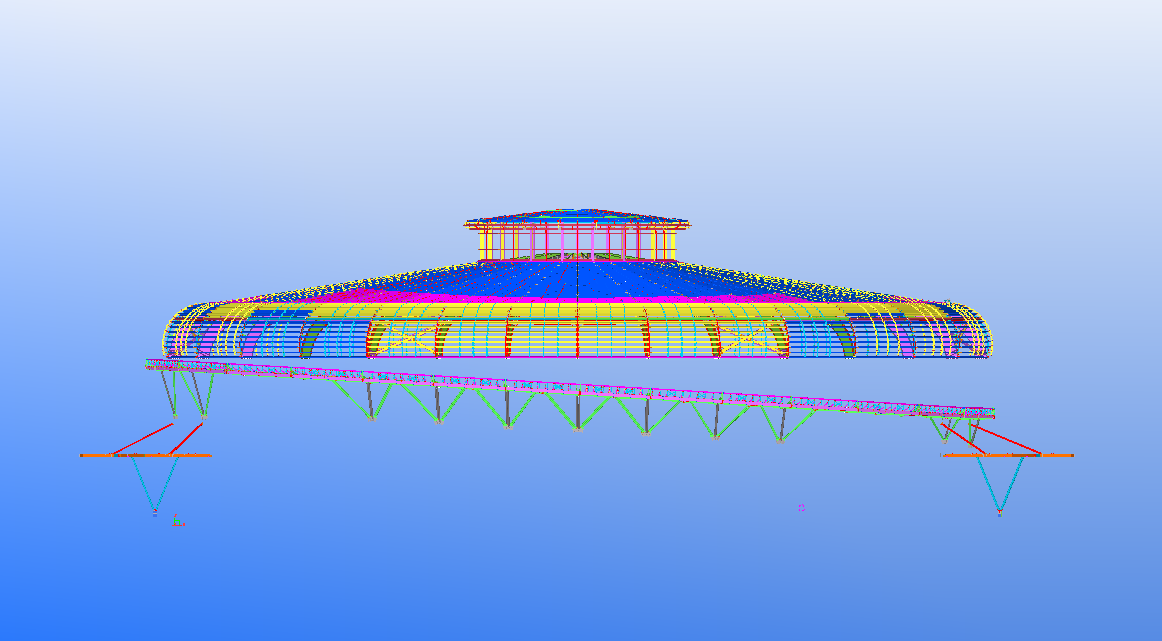

2. The Structure of Prefabricated Steel Building

Prefabricated steel buildings are commonly used in industrial projects such as factories, warehouses, logistics centers, and commercial buildings. With high durability, excellent load-bearing capacity, and resistance to harsh weather conditions, these structures meet the demands for longevity and robustness. Additionally, the convenience and cost-effectiveness of prefabricated steel buildings make them a top choice for many modern construction projects.

The structure of a prefabricated building includes key components such as:

The main framework

The main framework acts as the backbone of the structure. It is responsible for supporting, bearing loads, transmitting forces, and enhancing the rigidity and stability of the prefabricated steel building. The framework includes the primary truss system, bracing system, and purlin system. It is designed to be robust and utilizes high-quality, premium materials. These components require a reputable steel fabricator like Pebsteel to ensure the best quality for the project.

Secondary Structure

These are the remaining parts needed to complete a prefabricated steel building. Depending on the nature of the project, engineers will optimize the use of secondary structures during the design phase. Common secondary structures in prefabricated steel buildings include: canopies, staircases, door systems, gutters, decorative trims, emergency exits, and maintenance walkways.

Enclosure Structure.

This structure is crucial for prefabricated steel buildings. It serves to define spaces, create functional zones, and protect the building from external environmental impacts. Additionally, the enclosure structure ensures the aesthetic appeal of the entire project. With a diverse range of materials in various shapes and colors, all design requirements of the project are met.

The enclosure structure includes the roof and prefabricated house walls, which are shaped from readily available materials such as roofing sheets, cement boards for interior and exterior use, floor panels, steel sheets, bricks, wood, and tiles.

3. Types of Materials for Prefabricated Building Walls.

Prefabricated building walls are part of the building’s enclosure structure. When designing, engineers will choose suitable wall solutions based on the characteristics of the project. Here are some commonly used types of prefabricated building walls:

3.1. Common roofing sheets

- Advantages: This material is lightweight, comes in a variety of colors, and has multiple functions such as insulation and light transmission. The roofing sheets can be manufactured to meet specific requirements for use in steel building construction.

- Disadvantages: The soundproofing capability of the roofing sheets is limited, which can affect activities inside the steel building.

3.2. Sandwich panels

- Advantages: Also known as panel roofing sheets or panel walls, sandwich panels are notable for their effective soundproofing, insulation, heat resistance, and noise reduction. They can be used in various positions such as walls, ceilings, and floors. The roofing sheets come in many colors to meet different usage needs: as partitions, ceiling panels, doors, etc.

- Disadvantages: They have only average heat and load resistance. Cutting them to change sizes as needed is limited due to their rigid structure. They are not the optimal material for shielding areas that are damp or exposed to water.

3.3. Concrete

- Advantages: There are many types to choose from, such as regular concrete, lightweight concrete panels, and cement boards. The superior features of this material include fire resistance and the ability to withstand high temperatures. It is lightweight, which does not put pressure on the foundation of the building. It is safe for human health and environmentally friendly throughout its usage.

- Disadvantages: Not all concrete panels can be used as cladding walls. Some concrete panels are weak and not sturdy enough to meet the requirements for partition walls in prefabricated steel buildings. Therefore, careful consideration is needed to ensure effectiveness when using them.

3.4. Concrete Bricks

The current trend is to use concrete bricks instead of traditional bricks due to their more effective functionality.

- Advantages: The type of brick used is lightweight foam concrete, which helps reduce the load on the structure. This material is highly rated for its ability to withstand storms and strong external impacts.

- Disadvantages: Construction requires meticulous work and takes more time. The material cannot be reused.

3.5. Wood

- Advantages: Fully known as wall cladding wood, it is hard, durable, termite-resistant, water-resistant, and waterproof. It comes in panel form with consistent sizes for flexible use in construction.

- Disadvantages: It is not 100% wood but also contains sand and glue. Cleaning during use is limited.

3.6. Glass

- Advantages: There are various types of glass for different purposes: tempered glass, clear glass, colored glass, reflective glass, safety glass, etc. It has high durability if used correctly. The thickness of the glass should be chosen based on the needs and purpose.

- Disadvantages: It is expensive, requires high technical skills for installation, and is selective for different types of projects.

4. Pebsteel – Quality Prefabricated Steel Building Construction Unit

Pebsteel is proud to be a leading provider of European-standard prefabricated steel building solutions and steel structures on the market. Pebsteel’s prefabricated steel buildings are present in over 50 countries, including Vietnam, Laos, Thailand, Japan, etc.

With a strong team focused on professional training and work ethics, Pebsteel is committed to providing professional and dedicated services. With practical experience, Pebsteel is confident in its ability to undertake large-scale, high-demand projects.

Pebsteel always aims to create high-end projects that meet all the elements: architecture, engineering, functionality, and aesthetics.

The above information relates to prefabricated steel wall systems in the design and construction of prefabricated steel buildings. If you have any further questions, please contact us via email marketing@pebsteel.com.vn or phone number +84 908 883531 for steel building guide on the most detailed steel building construction process.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.