In the rapidly evolving landscape of modern industrial construction, the demand for infrastructure that combines durability, speed, and cost-effectiveness has never been higher. As businesses aim to expand operations and reduce downtime, the choice of materials becomes a key factor in project success. Structural steel has emerged as a leading solution, redefining the standards for warehouses, factories, and industrial complexes.

Structural steel is essential in industrial projects due to its high strength, excellent load-bearing capacity, and long-term efficiency. It enhances operational performance while optimising construction costs. Compared with traditional construction methods, modern steel applications, especially in prefab and pre-manufactured steel buildings, provide unmatched versatility. These are one of the most innovative structural steel solutions that you could apply to your business.

1. What is Structural Steel? The Backbone of Modern Industry

Structural steel is a complete framing system of columns, beams, bracing, and connections, prefabricated in factories and assembled on site. This approach ensures high quality control and significantly faster construction, forming the basis of pre-engineered steel buildings.

Its key advantage is a high strength-to-weight ratio, allowing long clear spans with minimal columns—ideal for industrial, warehouse, and logistics projects. Structural steel also integrates well with cladding, insulation panels, glazing, and concrete, delivering durable, flexible, and cost-efficient building solutions when properly protected against corrosion.

2. 5 Key Applications of Structural Steel Across Industries

The versatility of steel has enabled it to transcend traditional boundaries, making it the material of choice across diverse sectors. Structural steel is commonly used in factories, warehouses, production facilities, and various types of industrial infrastructure. It optimises space, increases productivity, and allows easy project expansion. Below are the five primary sectors where this material is enhancing construction.

2.1. Industrial and Warehousing Sectors

Industrial manufacturing and logistics demand infrastructure characterised by large spans, wide openings, and substantial clear heights. Structural steel meets these strict demands through robust design, rapid execution, environmental sustainability, and economic efficiency.

Innovative steel solutions increase factory productivity and reduce maintenance and upgrade costs. They save construction time thanks to standardised, easy-to-assemble components. This speed is precisely why prefab steel building designs are dominating the industrial landscape.

- Pre-engineered Factories: Utilising clear-span frames allows for the seamless arrangement of production lines, overhead cranes, and forklift traffic. With components manufactured in controlled factory settings, on-site teams can assemble structures rapidly while maintaining strict quality control. The building envelope typically uses single-layer sheeting for basic needs or insulated panels for thermal and noise control, often integrated with louvres and skylights to maximise energy efficiency.

- Prefab Logistics Warehouses: Modern logistics require wide doors for container access and optimised pallet heights. Steel frames provide the necessary vertical clearance, allowing for easy future expansion. While the initial investment is significant, the cost per square meter decreases as the scale increases.

Steel buildings for factories and warehouses: durable, efficient, and scalable for industrial needs

2.2. Commercial and Public Structures

Service complexes, sports arenas, and event centres require large column-free spaces and guaranteed safety standards. Modern technologies such as lightweight steel, high-strength steel, and modular frames help optimise costs and timelines. Smart design and standardised production deliver high construction efficiency.

- Office Buildings: Investors increasingly favour steel for its rapid erection time, allowing businesses to commence operations sooner. The flexibility of steel allows for easy vertical or horizontal expansion without disrupting daily activities.

- Shopping Malls: Steel frames create open floor plans ideal for flexible retail layouts. Combined with glass facades and louvres, these structures optimise energy consumption for lighting and air conditioning.

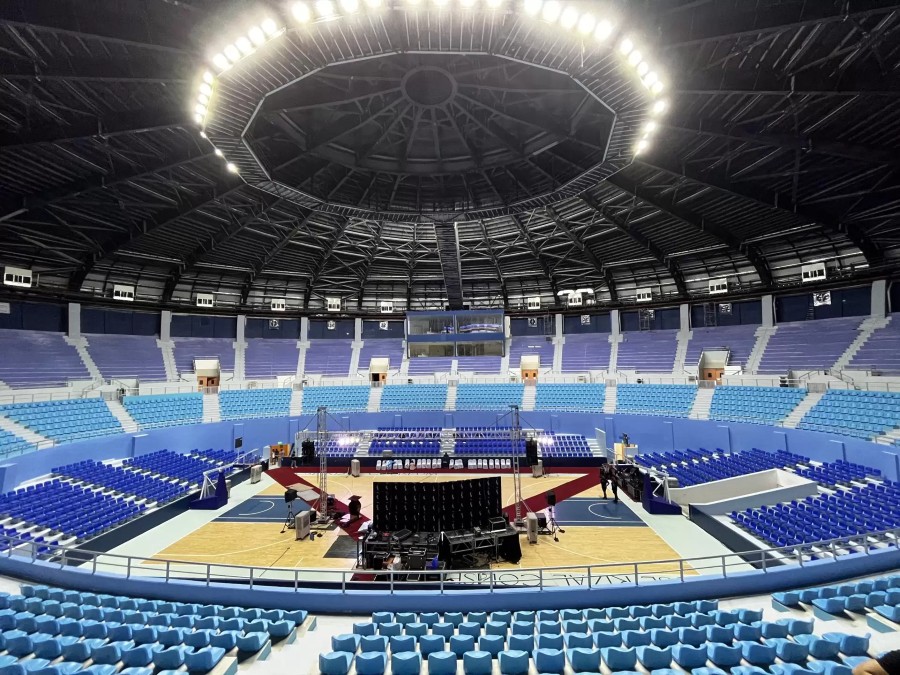

- Stadiums & Arenas: Utilising space frames or truss systems, engineers can bridge massive spans required for stadiums. Structural steel enables segmented assembly, reducing weather-related risks and construction duration.

- Event Spaces: For temporary exhibitions or stages, steel allows for quick assembly and disassembly, making it a reusable asset for peak seasons.

- Safety & Fire Protection: High-occupancy buildings require strict vibration control and clear evacuation routes. Regular fire drills and inspections of emergency exits are critical. For in-depth safety compliance, referring to regulations on intumescent painting for steel is highly recommended.

Steel Structure Applications in Stadium Grandstand Construction

2.3. Residential Applications

While reinforced concrete was once the standard for Vietnamese homes, the trend is shifting. Homeowners now prefer structural steel for its durability, aesthetics, and environmental friendliness.

- Roofs & Balconies: Steel trusses support flexible roof designs and efficient drainage. Combined with polycarbonate sheets, they create bright, durable open spaces.

- Mezzanines & Staircases: Steel staircases and mezzanines increase usable living area without adding excessive dead load to the foundation. Pre-drilled components allow for tidy installation in narrow urban spaces.

- Open Living Spaces: The “Clear Span” capability eliminates intermediate columns, allowing for open-concept living rooms and kitchens. This flexibility allows homeowners to repurpose rooms without structural intervention.

Expert Insight: Successfully implementing these designs requires a solid understanding of technical blueprints. Homeowners and contractors should be familiar with reading structural drawings to make informed decisions during construction and management.

2.4. Transport Infrastructure

Innovative structural steel solutions help save material and labour costs. Construction timelines are shortened due to standardised components and optimised designs. This makes steel the superior choice for infrastructure projects that minimise traffic disruption.

- Steel Bridges: From truss and suspension to cantilever bridges, steel adapts to various geological conditions and load requirements. Management units can easily replace or reinforce specific sections upon detecting fatigue, ensuring continuous safety.

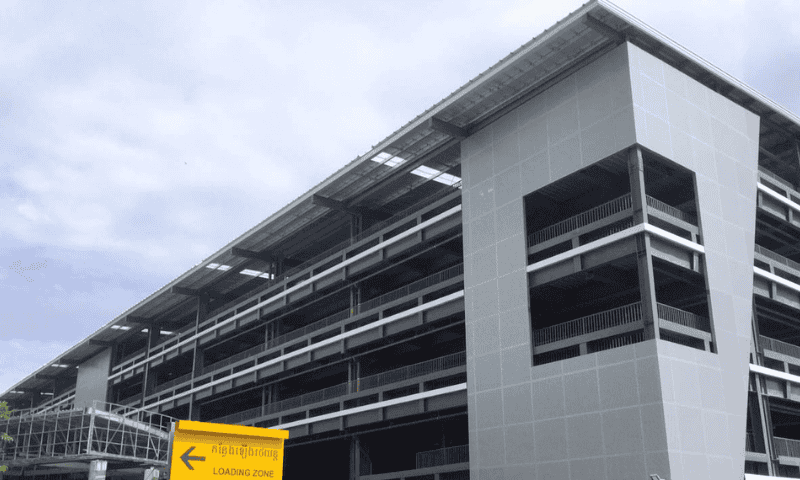

- Stations & Parking Structures: Multi-story parking lots and terminal roofs use steel to accelerate project completion. The open structure allows for natural ventilation and lighting, which is essential for 24/7 operations.

- Pipe Racks: In industrial plants, steel racks support pipelines and cable trays, providing a secure foundation for these essential components. Modular designs allow for line expansion without shutting down the entire system.

A multi-storey parking facility using steel structures to optimise traffic flow.

2.5. Energy and Agriculture

Innovative structural steel provides high efficiency, durability, and cost and time savings. It is a key solution for improving performance and effectiveness in industrial projects. This is evident in the energy and agricultural supply chains.

- Solar & Wind Energy: Solar panel mounting systems rely on steel for rigidity and wind resistance. Similarly, wind turbine towers require steel to withstand immense dynamic loads and fatigue. In coastal areas, strict adherence to repainting schedules is necessary to combat salt corrosion.

- Greenhouses & Farming: Steel frames offer a termite-free, hygienic solution for agriculture. Farmers can easily expand pre-manufactured steel buildings for livestock or crops by adding new spans rather than rebuilding.

- Cold Storage: Agricultural cold storage utilises specialised thermal panels and condensation-resistant details. Maintaining door seals and dock levellers is critical to preventing thermal loss and preserving product quality.

An image of a pre-engineered steel cold storage warehouse under construction by Pebsteel.

Helpful Information: Pre-Engineered Buildings: The Smart Choice for Modern Construction

3. Essential Considerations for Optimising Structural Steel Projects

To ensure that structural steel design not only meets immediate operational needs but also stand the test of time, project owners must address several critical factors during the planning and execution phases.

- Strategic Planning: When initiating a prefab steel building project, contractors must meticulously calculate key parameters, including clear span, load-bearing requirements, and future scalability. These technical specifications must align seamlessly with the investor’s timeline and budget constraints.

- Environmental Adaptation: For projects in specific climates, such as coastal areas exposed to salt or regions prone to severe storms, construction teams must apply high-quality anti-corrosion coatings and advanced joint-sealing techniques. These measures are essential for prolonging the facility’s lifespan.

- Composite Structural Integrity: To enhance the durability and rigidity of beams, floors, and columns, contractors often employ composite steel-concrete solutions. This combination leverages the compressive strength of concrete and the tensile strength of steel for superior performance.

Selecting a structural steel provider should be based on experience, production technology, and reputation. Design consultation and technical support are also crucial to ensure project quality.

Key factors to ensure durable, efficient, and long-lasting structural steel projects

Structural steel has firmly established itself as the preferred choice for modern contractors due to its rapid deployment, cost efficiency, minimal environmental impact, and aesthetic versatility. From residential housing and commercial complexes to transport infrastructure and logistics storage, the applications of this material are limitless.

If you are seeking a reputable partner for design, manufacturing, and prefabrication steel building solutions, Pebsteel stands out as a leading steel structure fabricator in Vietnam, trusted by global corporations for complex industrial projects. With over 30 years of experience, Pebsteel has successfully delivered more than 6,000 major projects across 50 countries, earning the trust of industry giants such as General Electric, Aeon, Budweiser, Heineken, and P&G.

If you are looking for comprehensive solutions in steel structure construction, contact Pebsteel via email at marketing@pebsteel.com.vn or phone at (+84) 908 883 531 for consultation!

Disclaimer: This article is intended for general information purposes regarding the pre-engineered steel building industry. For specific details or tailored solutions, please contact Pebsteel directly.