Hot rolled steel is a type of raw material widely used in the construction industry, especially in modern steel structures. The product offers high durability and excellent load-bearing capacity, making it suitable for fabrication, construction, and mechanical manufacturing. In this article, steel structures explained, Pebsteel introduces the features and applications of hot rolled steel, which is commonly applied in buildings using structural steel components.

1. What is Hot Rolled Steel?

Hot rolled steel is a type of steel that is processed at high temperatures, typically above the recrystallization temperature of steel. This process involves rolling the steel at temperatures above 1700°F, which allows it to be shaped and formed more easily. The high temperature not only makes the steel easier to work with but also improves its structural properties, making it ideal for various applications in construction and manufacturing, particularly in steel structures.

2. Characteristics of Hot Rolled Steel

Hot rolled steel possesses several distinctive characteristics that make it suitable for a wide range of uses. These characteristics include:

- Surface Finish: Hot rolled steel typically has a rough, scaly surface due to the cooling process and the exposure to oxygen at high temperatures.

- Strength and Durability: The process of hot rolling enhances the strength and durability of the steel, making it ideal for structural applications in steel structures.

- Ductility: Hot rolled steel is more ductile, meaning it can be shaped and formed without breaking.

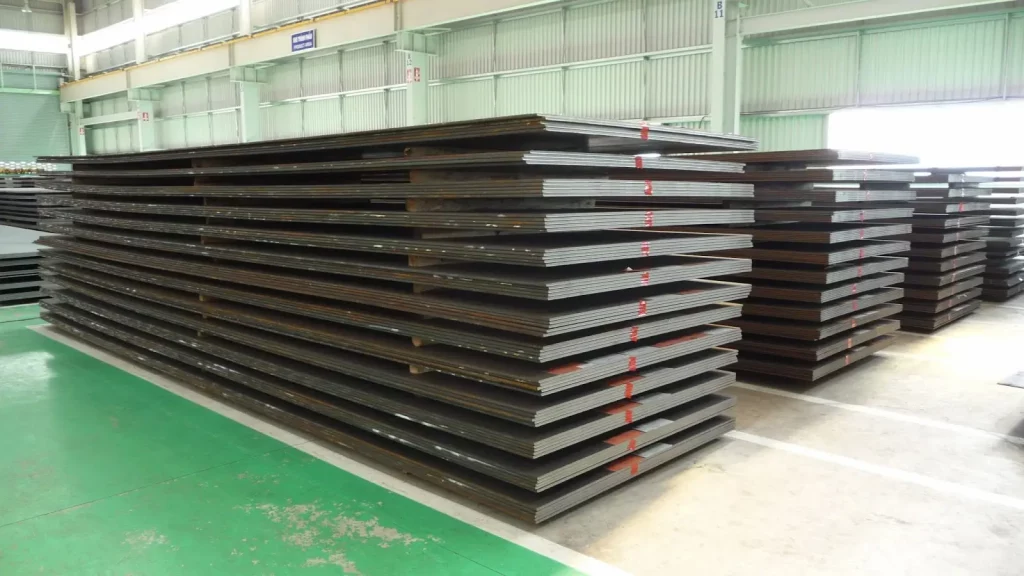

- Size and Shape Variety: It is available in a variety of shapes and sizes, including beams, bars, sheets, and plates, making it versatile for different applications.

3. Properties of Hot Rolled Steel

Hot rolled steel has specific properties that distinguish it from other types of steel:

- Tensile Strength: Hot rolled steel has a high tensile strength, making it suitable for structural applications where load-bearing is critical.

- Flexibility: It is more flexible and easier to work with compared to cold rolled steel, which allows for more complex shapes and designs.

- Weldability: Hot rolled steel is easier to weld due to its lower carbon content and less strict tolerances.

4. Kinds of Rolled Steels

Rolled steels can be broadly categorized into two types: hot rolled steel and cold rolled steel.

4.1. Hot Rolled Steel

Hot rolled steel is rolled at high temperatures and is used in applications where precise shapes and tolerances are not required. Common products include:

- Structural Beams: Used in construction for frameworks and supports.

- Rail Tracks: The high strength and durability make it ideal for railway tracks.

- Sheet Metal: Used in automotive and appliance manufacturing.

4.2. Benefits of Hot Rolled Steel

Hot rolled steel offers several benefits, making it a popular choice for various applications:

- Cost-Effective: The manufacturing process is simpler and less expensive, making it a cost-effective option for many applications.

- Ease of Work: It is easier to work with due to its ductility and flexibility, allowing for more complex shapes and designs.

- Availability: Hot rolled steel is readily available in various shapes and sizes, providing versatility for different projects.

4.3. Cold Rolled Steel

Cold rolled steel is processed at room temperature, resulting in a smoother finish and more precise dimensions. Common products include:

- Steel Tubes: Used in mechanical applications and furniture manufacturing.

- Strips and Bars: Used in precision engineering and construction.

- Sheets: Used in automotive bodies and appliances where a smooth finish is required.

4.4. Benefits of Cold Rolled Steel

Cold rolled steel offers its own set of advantages, particularly for applications requiring precision and a smooth finish:

- Higher Precision: The cold rolling process results in more precise dimensions and tighter tolerances.

- Smooth Finish: Cold rolled steel has a smoother surface, making it ideal for applications requiring a high-quality finish.

- Increased Strength: The cold rolling process increases the yield strength and hardness of the steel.

5. Differences Between Hot Rolled vs Cold Rolled Steel

The main differences between hot rolled and cold rolled steel lie in their processing methods and resultant properties:

- Processing Temperature: Hot rolled steel is processed at high temperatures, while cold rolled steel is processed at or near room temperature.

- Surface Finish: Hot rolled steel has a rough, scaly surface, whereas cold rolled steel has a smoother, shinier finish.

- Tolerance and Precision: Cold rolled steel has tighter tolerances and more precise dimensions compared to hot rolled steel.

- Mechanical Properties: Cold rolled steel is harder and has a higher yield strength, while hot rolled steel is more ductile and easier to work with.

| Category | Hot rolled steel | Cold rolled steel |

| Thickness | from 0.9mm | from 0.15mm – 2mm |

| Finished product features | The original color is blue-black, oily. | There are bright white spots, gray, with gloss. |

| Aesthetics | Poor aesthetics, no sharp edges, not neat but shaggy. | High aesthetic with a beautiful flat surface, no shaggy, no ripples |

| Accuracy | Uncontrollable, Low accuracy | Controllable, High accuracy |

| Tolerance | High deviation | Low deviation |

| Features | Easy to change features, shapes, sizes at high temperatures. | It doesn’t change the feature, it just changes the shape. |

| How to preserve | It can be stored outside without the protective package. | There must be external packaging and storage in the house to avoid rust. |

| Application | – Used as cold rolled steel, the components do not require too high aesthetics – Used for fabricating the production of bearing steel structural frames. |

The details and products have aesthetic requirements, high accuracy and thickness as desired: corrugated steel, frills, gutters, purlins,.. |

| Price | Low | High |

Understanding the differences between hot rolled and cold rolled steel, along with their respective benefits and applications, is crucial for selecting the right material for your project. Hot rolled steel, with its ease of workability, cost-effectiveness, and versatility, is ideal for construction and structural applications. On the other hand, cold rolled steel, with its precision, smooth finish, and increased strength, is suitable for applications requiring high-quality finishes and exact dimensions. Both types of steel play vital roles in the construction and manufacturing industries, contributing to the development of robust and efficient steel structures.

The above is information about hot rolled steel materials and practical features, applications. If you have questions that need to be answered, please contact at the following email marketing@pebsteel.com.vn or phone number +84 908 883 531 for specific advice.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.