The trend for construction and design of pre-engineered steel factories is currently being chosen by many enterprises and companies due to outstanding advantages that the construction brings. Join Pebsteel to read this article and find out why the design of pre-engineered steel factories are preferred by many enterprises.

1. The trend of pre-engineered steel factories in various fields

Pre-engineered buildings are more and more preferred in Vietnam and in many types of construction from industry, commerce, and civilian. Having exceptional advantages of quick construction time, and optimizing for material costs; pre-engineered steel buildings have become a construction trend chosen by many enterprises.

2. Pros of pre-engineered steel factories

Pre-engineered steel is chosen to replace most the conventional reinforced concrete by many contractors and investors because of these advantages, as follows:

2.1 Safe and quick construction

The construction and design of steel-frame factories include three steps: foundation, framing, sheeting, and accessories with steel components which are exactly processed and checked at the factory. Because of that, the construction time of pre-engineered steel buildings will be considerably shortened in comparison with the common construction methods (using concrete, cement, bricks, mortar,…). In conventional, the time of designing pre-engineered steel factories lasts from 7 to 10 days, the progress of processing lasts from 6 to 8 weeks, and the erection needs about 4 weeks to finish. On average, the construction of pre-engineered steel factories can be done from 3 to 4 months, from the design process to the total erection.

2.2 Ability to reuse materials and expand the structure

Besides reliable structures, pre-engineered steel buildings also have longevity up to dozens of years, in case they are used and maintained in the right way. The components of pre-engineered steel buildings have content, which is highly recycled or has no detriment; helping to decrease the waste from the procedure, and simultaneously optimizing the material costs and maintenance expenses while still ensuring the quality. The steel components such as column, rafter, purlin, and bolt… can also be reused or recycled in the future.

The ability to expand the structure also must be considered in the consultation and design of pre-engineered steel-frame factories.

From that, the construction organization proposes the most suitable design solution, which is to prevent the impossibilities, or cost-consuming of foundation, and load-bearing frame due to the lack of beginning estimates.

In current days, many contractors choose the Lean-to rafters of Pebsteel to expand their manufacturing facilities.

2.3 High aesthetics and flexible applications

Pre-engineered structural steel doesn’t only have the steady structure, but also aesthetics and high applicability. In addition to the popularity in civil, commercial buildings such as high-rise buildings, warehouses, factories, hangars, shipyards. Pre-engineered steel can be combined with other materials like wood, glass, concrete, stone to improve the aesthetics for some construction like resorts, commercial malls, hotels, convention centers, hospitals, stadiums,…

3. Pebsteel’s quoting process for designing factories

With the goal to bring high-quality pre-engineered steel factories to the customers with affordable prices, Pebsteel provides the quoting progress for designing factories clearly, transparently, and in details as following:

- Discussing and consulting ideas for the customers: based on the customers’ wishes and demands, Pebsteel will suggest some models of suitable factories .

- Suggesting and proposing appropriate methods to implement the project: After the customers choose a suitable pre-engineered steel factory model, Pebsteel will proceed to sketch the factory design drawings. At the same time, the company will also propose optimal methods for the use of materials and appropriate construction time for the customers.

- Signing the contract and implementing the project: In case the customers accept the contract from Pebsteel, the two sides will sign it, and the company will quickly deploy the project for the customers.

See more: Quotation Of Warehouse Construction Costs

4. Great design models of factories by Pebsteel

Below are some impressive, high-quality pre-engineered factories of Pebsteel that the customers can refer to:

A garment factory in Vietnam

The project of a garment factory in Vietnam, which is deployed to build by Pebsteel in 2016, with the scale up to 3000 square meters

A steel mill in Bangladesh

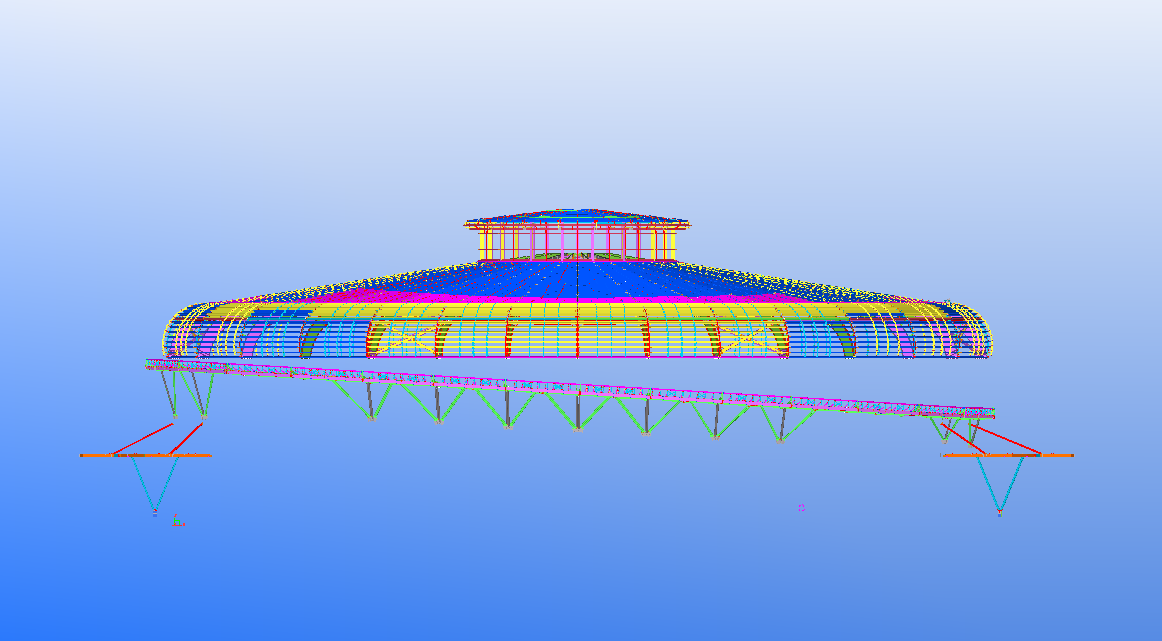

One of the Pebsteel’s pre-engineered steel factory projects that give an impression is the steel works factory in Bangladesh. The factory is mainly used for mechanical, metallurgical fields with the area up to 21.730 square meters.

An engine parts factory in Vietnam

In 2010, the car assembly factory was officially begun to build in Vietnam by Pebsteel, with the total area of 25.000 square meters.

A food factory in the Philippines

The food factory in the Philippines has the area of 13.240 square meters, which Pebsteel constructed in 2018.

An animal feed factory in the Philippines

In 2017, Pebsteel finished an animal feed factory in the Philippines, with the project’s scale up to 3530 square meters.

The above article gives relevant information about the current trend of construction and designs of pre-engineered steel factories. For all details about the design process of pre-engineered steel factory projects, please contact Pebsteel at email Marketing@Pebsteel.com.vn or phone number +84 908 883531 for detailed consultation.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.