The construction cost is one of the key factors that customers need to consider before deciding to carry out the construction of a prefabricated steel factory. Together with Pebsteel, let’s review the cost ranges and related factors that directly affect the steel factory construction cost in 2025.

1. Steel factory construction costs

The construction cost of a prefabricated steel factory depends on many factors such as detailed components, location, environmental conditions, etc. In particular, the size and scale of the factory are the main factors that directly affect the total cost of the construction project. Additionally, the cost may fluctuate based on the construction schedule, the type of materials, or any additional structural design requested by the client.

Each type of steel-framed factory or steel shed building, depending on its scale, intended use, and materials, will have different pricing.

2. Detailed quotation for each construction item of the factory structure

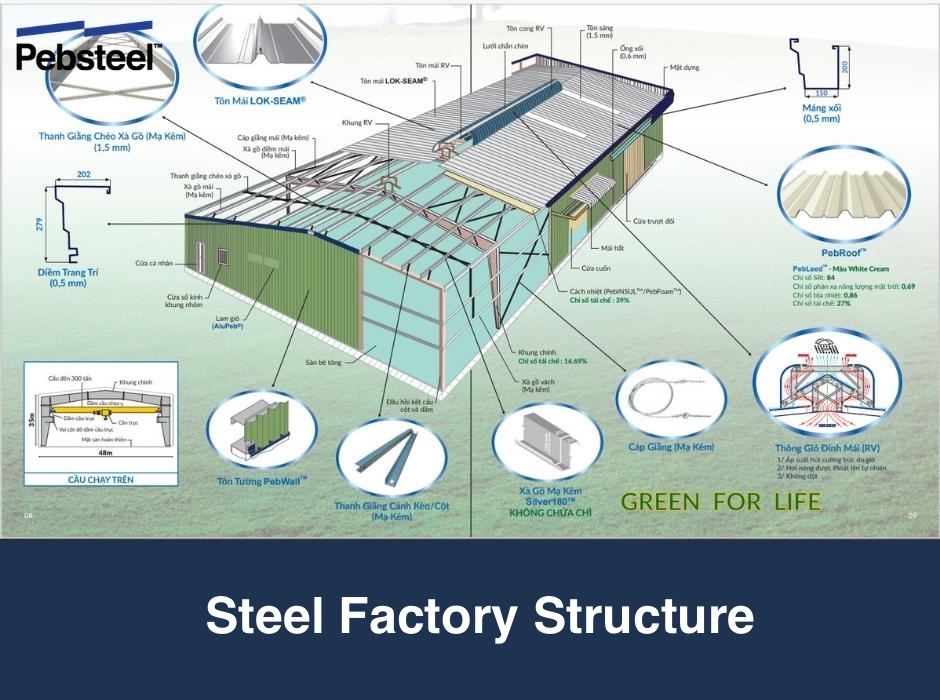

There are 5 main items in a standard steel factory construction costs, including: foundation structure, main frame system, roofing system, auxiliary structural system, and additional accessories.

Analyzing and estimating the cost of each item is a crucial step in the planning and evaluation process of a steel-framed factory construction project. Below is a more comprehensive overview of the items:

2.1 Cost Estimation for the Foundation Structure

The factory foundation is the lowest part of the structure, supporting the load and anchoring the factory to the ground. This part ensures the load-bearing capacity for the floors, equipment, and people inside the factory.

The foundation cost is summarized in a package that includes:

- Reinforced concrete

- Foundation and base construction materials

- Floor coating

- Labor costs

2.2 Cost Estimation for the Steel Frame System

The steel frame system includes main components such as trusses, purlins, and bracing that have been manufactured and processed with precise dimensions and quantities according to technical drawings. The pre-engineered steel factory frames cost varies depending on the type of steel truss chosen by the client, the scale of the project, environmental factors (such as corrosion conditions, wind loads, geological factors), as well as the prices of raw materials at different times.

2.3 Cost Estimation for the Roofing System

The roofing system is typically made from thin-gauge steel and utilizes various modern technologies to serve different purposes depending on the project. This is an essential component for factories and any other types of construction projects.

Common types of roofing materials used in factory construction are classified based on the following factors:

- Location and Function: Roof sheets, wall panels, decorative sheets, skylight sheets, insulated sheets, etc. The unit price for each type of sheet will vary depending on the specific needs of the factory.

- Installation Characteristics: Screw-down sheets and standing seam sheets (not screw-down).

- Design: Depending on the technical characteristics and usage needs of each project, clients can choose the appropriate sheet structural steel design. At Pebsteel, common roofing types include PebWall®, LokSeam®, PebLiner™, PebRoof®, etc. Each type of sheet has its own specific function and installation requirements.

- Surface Treatment: Color-coated sheets, non-coated sheets (only galvanized or aluminum-zinc-magnesium alloy coated for corrosion resistance).

2.4 Cost Estimation for the Auxiliary Structural System

The factory structure will have an auxiliary structural system that includes windows, doors, shutters, canopies, roof ridge ventilation systems, crane systems, mezzanine floors, decorative facades (fascia), secondary walkways, and stairs. These elements enhance aesthetics and fulfill functions such as flood prevention, natural air circulation, and increasing the durability of the prefabricated factory, meeting all customer usage requirements.

2.5 Other Accessory Types

Additional accessories and techniques will be incorporated based on the specific needs of the factory. These technical systems must meet standards for fire prevention, communication, and the types of machinery and equipment related to the factory’s operations.

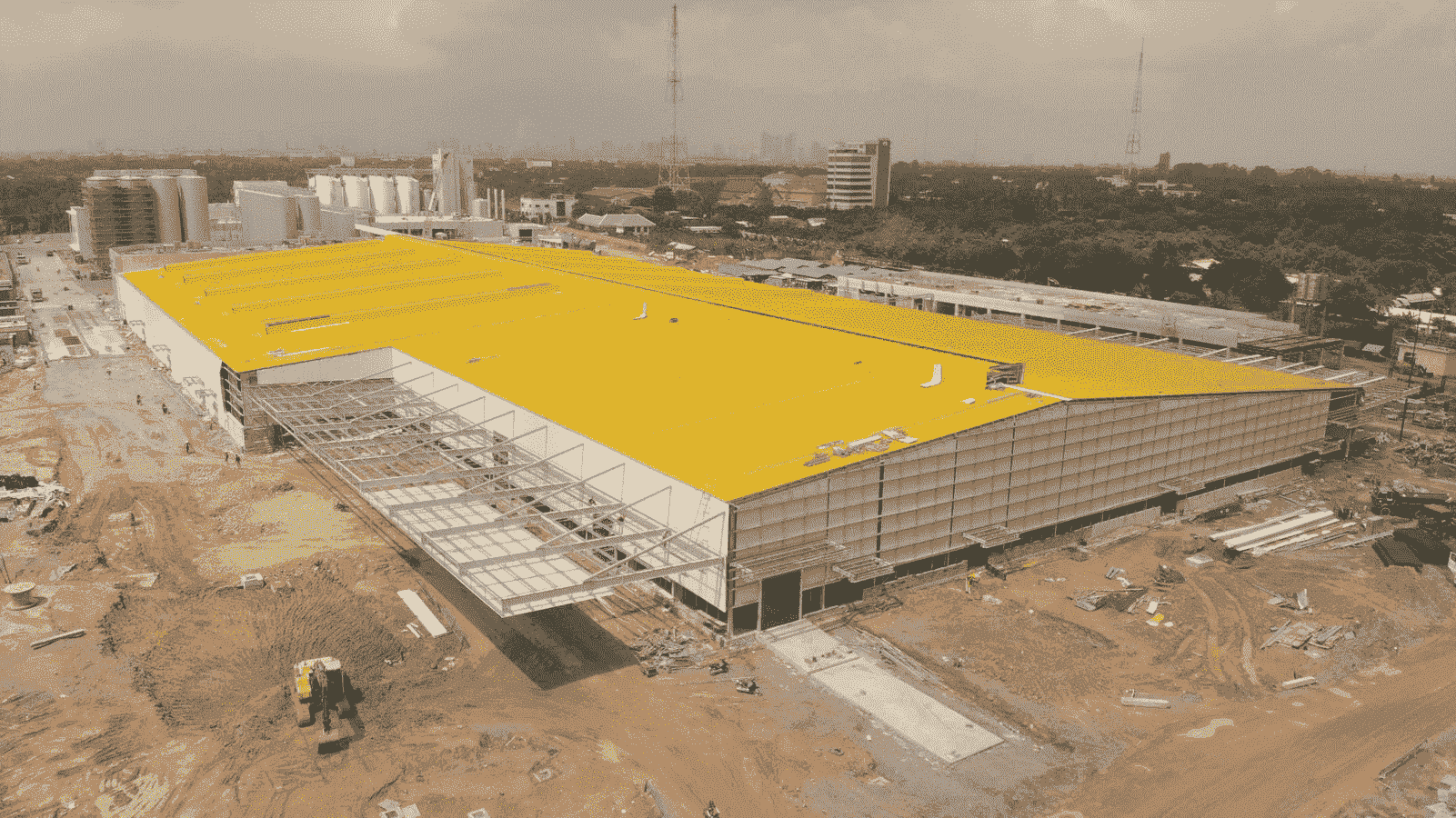

3. Structure of a Prefabricated Steel Factory

A prefabricated steel factory is a type of structure built from prefabricated steel components manufactured and processed in a factory with precise dimensions and quantities. These steel components are then transported to the construction site and assembled into a complete structure.

The structure of a prefabricated factory consists of four main parts:

- Main Frame System: Columns, trusses, and beams.

- Secondary Structure: Wall beams, purlins, braces, and bracing systems.

- Roofing and Enclosure Sheets: Roofing panels and wall cladding for the factory.

- Foundation System: The foundational support structure.

4. Common Types of Factories Today

Factories are primarily built for the purpose of manufacturing goods. Some factories also incorporate storage space or on-site office areas depending on the needs of the investor. Different construction methods for factories will incur varying costs. Below are three common types of factories today:

- Standard Factory: This type of factory structure often uses an iron or steel frame, brick walls, and roofing made from various materials (such as iron, steel, fiber cement, and plastic).

- Pre-Engineered Steel Factory: A factory with a steel frame and roofing made of steel.

- Reinforced Concrete Factory: A factory constructed primarily from reinforced concrete materials.

5. Cost Estimation Process for Prefabricated Steel Factory by Pebsteel

Pebsteel is one of the reputable construction contractors with over 30 years of experience, always striving to provide quality projects with the most optimal costs for customers. Pebsteel has a transparent pricing process along with solutions tailored to the needs of each customer, as follows:

- Consultation & Preliminary Drawing Provision: Pebsteel will investigate the detailed needs of the client to develop preliminary design drawings and propose solutions, materials, along with factory construction costs.

- Contract Signing: After the client reviews and accepts the proposal, Pebsteel will finalize the contract and any necessary legal procedures.

- Post-Contract Signing: After the contract is signed, Pebsteel will develop detailed technical drawings for production, processing, and assembly purposes.

6. Construction Process for Prefabricated Steel Factories by Pebsteel

The construction process for prefabricated steel factories includes seven main stages:

- Concept Development: Based on the client’s initial desires and ideas, Pebsteel will propose a comprehensive plan covering design, processing procedures, assembly, construction pricing, and project timelines.

- Solution Proposal: After reaching an agreement with the client, Pebsteel will provide optimal solutions for material usage, cost estimation, and construction timelines.

- Contract Signing and Project Implementation: Once the client agrees to the company’s solutions, both parties will sign the contract and proceed with the project.

- Technical Drawing Development: With the capabilities of over 100 experts and the use of modern design and material management software, Pebsteel is committed to satisfying clients with the factory structure design provided.

- Processing: The processing procedure is rigorous and utilizes modern equipment with seven steps:

- Steel cutting: CNC, Plasma, etc.

- Automatic welding.

- Surface cleaning of steel.

- Surface metal spraying.

- Protective painting of steel surfaces.

- Galvanization and alloy coating for purlins and panels.

- Transporting materials to the construction site. 100% of the products are inspected at the factory before delivery.

- Quick and Safe Assembly: All materials are packaged and transported to the construction site for assembly. Every assembly step is strictly monitored to ensure the highest quality.

- Warranty: Pebsteel offers a 2-year warranty for materials, a 3-year warranty against leaks, and a 10-year warranty for the structure to optimize usage efficiency and extend the lifespan of the project.

Important Considerations When Constructing Factory Structures

Deciding to construct a factory is a crucial step that significantly impacts the business and production model. Here are some key factors to consider to ensure the quality of the factory and optimized budget:

- Design: It’s essential to choose a reasonable structural design solution that meets functional, safety, sustainability, and aesthetic requirements for the factory. This design will also affect the overall construction cost of the entire project. Therefore, it must be detailed to avoid unexpected costs during construction.

- Material Quality: Using quality materials that meet industry standards will ensure the factory’s lifespan and help save on maintenance costs. This is a worthy investment when building a factory, as it will yield long-term benefits compared to opting for cheaper materials that may incur higher expenses later on.

- Choose a Reputable and Experienced Contractor: The assembly process of the factory must ensure precision and safety. In particular, ensuring safety during assembly is the most critical factor and must be strictly adhered to. Thus, selecting a reliable construction contractor is essential.

By paying attention to these aspects in the construction can help the investor to optimize costs, enhance construction quality, and ensure safety during the construction process.

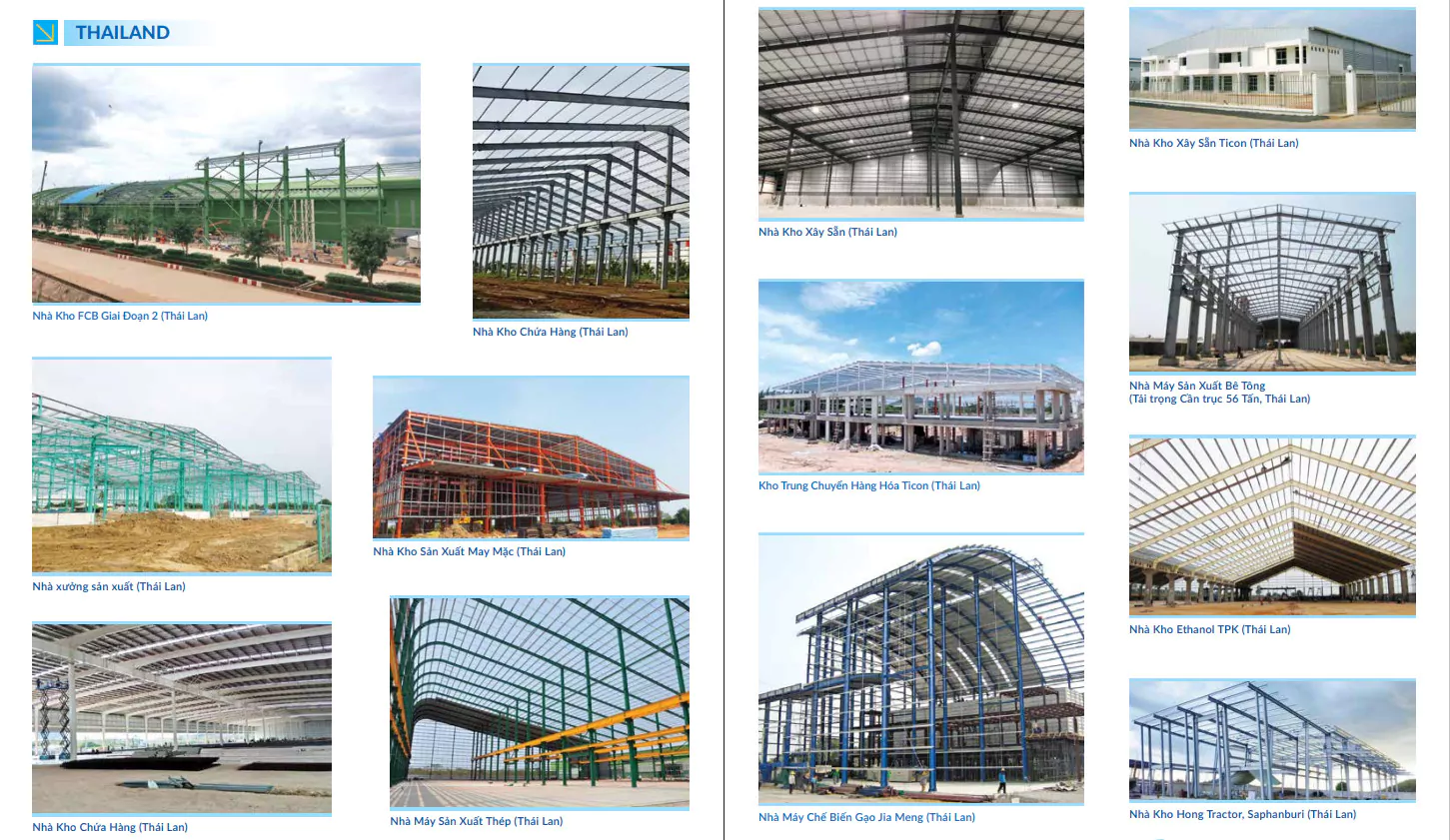

7. Notable Factory Construction Projects by Pebsteel

7.1. Optical Equipment Manufacturing Factory (Vietnam)

- Type of Construction: Factory, Workshop, Production

- Industry: Glass, Ceramics, and Household Goods

- Location: Vietnam

- Area / Weight: 4,950 sqm/1,213 mt

This optical equipment manufacturing facility demands stringent soundproofing and thermal insulation solutions while maintaining a spacious and aesthetically pleasing working environment. Pebsteel met the needs of both the client and contractor by utilizing the most suitable materials and design methods:

- Insulation Material: PebFoam™, along with the PebLiner™ roof cover and wall panels, offers superior thermal insulation and soundproofing capabilities.

- Roofing Panel: The PebSeam128® roof, made from PebLeed® material (White Cream AluPeb®), reflects solar energy effectively, reducing roof temperatures by up to 5°C. It also provides excellent corrosion resistance and outstanding waterproofing, especially in heavy rainfall environments.

- Wall Panels: PebWall® panels in Alumin color, made from AluPeb®, are installed horizontally to enhance aesthetic appeal while ensuring good corrosion resistance.

- Finishing Touches: The soffit under the canopy and the high-quality finishes on the corner trims and roof eaves enhance the overall beauty of the structure.

7.2. Building Material Production Factory (Vietnam)

- Type of project: Factory, Other

- Industry: Building materials

- Area / Weight: N/A /1,116 mt

- Location: Vietnam

7.3. Consumer Goods Manufacturing Factory (Vietnam)

- Type of project: Factory, Production

- Industry: Consumer goods

- Area / Weight: 13,210 sqm/742 mt

- Location: Vietnam

7.4. Shipyard (Philippines)

- Type of project: Other, Shipyard

- Industry: Aircraft hangars and Shipbuilding

- Area / Weight: 11,752 sqm/1,426 mt

- Location: Philippines

This is the tallest shipyard in the Philippines (2018) with a height of 33.5m, designed, manufactured, and constructed by Pebsteel. To enhance the durability of the structure in a highly corrosive environment, Pebsteel used the best materials for the roof and wall purlins: Silver180®.

Additionally, the project features a clear span frame without middle columns, coated with protective polyurethane paint to improve corrosion resistance while optimizing the budget for the investor compared to hot-dip galvanized steel.