The Canopy roof in a factory, also known as a shelter roof or awning, is an extremely important component that plays a role in protecting the factory from sun and rain while enhancing the aesthetic appeal of the structure. Let’s learn about the various types of factory Canopy roofs and their applications in the following article with Pebsteel.

Read more: Construction Of Pre-engineered Steel Factory 2023

1. What is a canopy roof?

A Canopy roof is a type of awning installed in the entrances and walkways of industrial factory buildings with the purpose of providing shade and protection from rain. Additionally, Canopy roofs also add aesthetic value to the entire factory structure.

This type of roofing has been widely applied in various construction projects, including both residential and industrial ones. Canopy roofs have become an indispensable component of factory buildings and industrial areas. The materials used for Canopy roofs are highly diverse and depend on the architecture of the main structure, aesthetic requirements, and investment capital.

Read more: 6 Most Popular Types Of Factory Metal Roofs In 2023

2. Types of Factory Canopy

Currently, in the market, there are four common options for factory Canopy roof types, classified based on the materials used to create the shelter, including metal, tempered glass, polycarbonate roofing sheets, and aluminum. Each type of shelter roof has its own distinctive characteristics and appearance due to the unique properties of these materials.

2.1. Canopy made of corrugated iron

Canopy roofs which made of corrugated iron are commonly used in various factory and prefabricated warehouse projects. This type of roof is used to provide shade at entry and exit points. The advantages of corrugated iron Canopy include cost-effectiveness, rapid construction, and relatively long lifespan. Typically, these roofs are made from SS400 or Q235 steel, with the thickness customized to meet the specific requirements of the project.

2.2. Canopy made of tempered glass

Choosing to use tempered glass Canopy roofs brings perfection to exterior decoration. Canopies are typically applied in large spaces, serving both residential and commercial purposes. Tempered glass Canopy systems often utilize tempered glass or multi-layer safety laminated glass. The construction and installation of Canopies on reinforced steel frames are carefully executed, using specialized structural adhesives for added safety. Additionally, the incorporation of accessories like spider enhances the durability of the Canopy roof.

Tempered glass canopy roofs have the advantage of having superior aesthetics, which produce a classy and appropriate appearance for various architectural styles. Additionally, it is fairly easy and straightforward to clean the tempered glass Canopy’s surface.

2.3. Canopy roofing with polycarbonate sheet

Thanks to its distinctive technical characteristics, Canopy roofing polycarbonate sheets can address issues that other Canopy types constructed from steel composite roofing cannot meet, such as durability, shaping, and aesthetics. This type of roof is often applied in facilities that combine offices, such as structures requiring aesthetics and high durability.

Polycarbonate sheet canopy roofs offer numerous advantages, including good insulation, high impact resistance, UV resistance, lightweight, ease of installation and maintenance, and adaptability to various architectural designs. However, the limitation of this material is its relatively high cost, making it typically suitable for large-scale factory projects with substantial investment. Typical applications for this type of Canopy roof include airports, subway systems, shopping centers, large stores, luxury residential buildings, etc.

2.4. Aluminum roofing canopy

Aluminum Canopy roofs are a type of shelter constructed from aluminum sheets (often referred to as alu panels) – a material that combines aluminum alloy and plastic. This material is relatively new in the application of roofing for factory structures. It is commonly used in cladding for service and office buildings. Aluminum Canopy roofs offer several advantages, such as lightweight, various colors and patterns, ease of cleaning, and excellent sound and thermal insulation properties.

3. Applications of Canopy roofs in Pre-engineered steel buildings

The application of Canopy roofs offers several advantages, including the ability to protect structures from the harsh effects of weather. Furthermore, Canopy roofs enhance the aesthetic value of pre-engineered buildings. Therefore, Canopy roofs have become an integral part of the design process for both industrial and residential projects. Below are some applications of Canopy roofs in prefabricated factory buildings:

- Balcony and window awnings for shade and rain protection.

- Entrance awnings for office buildings and apartments.

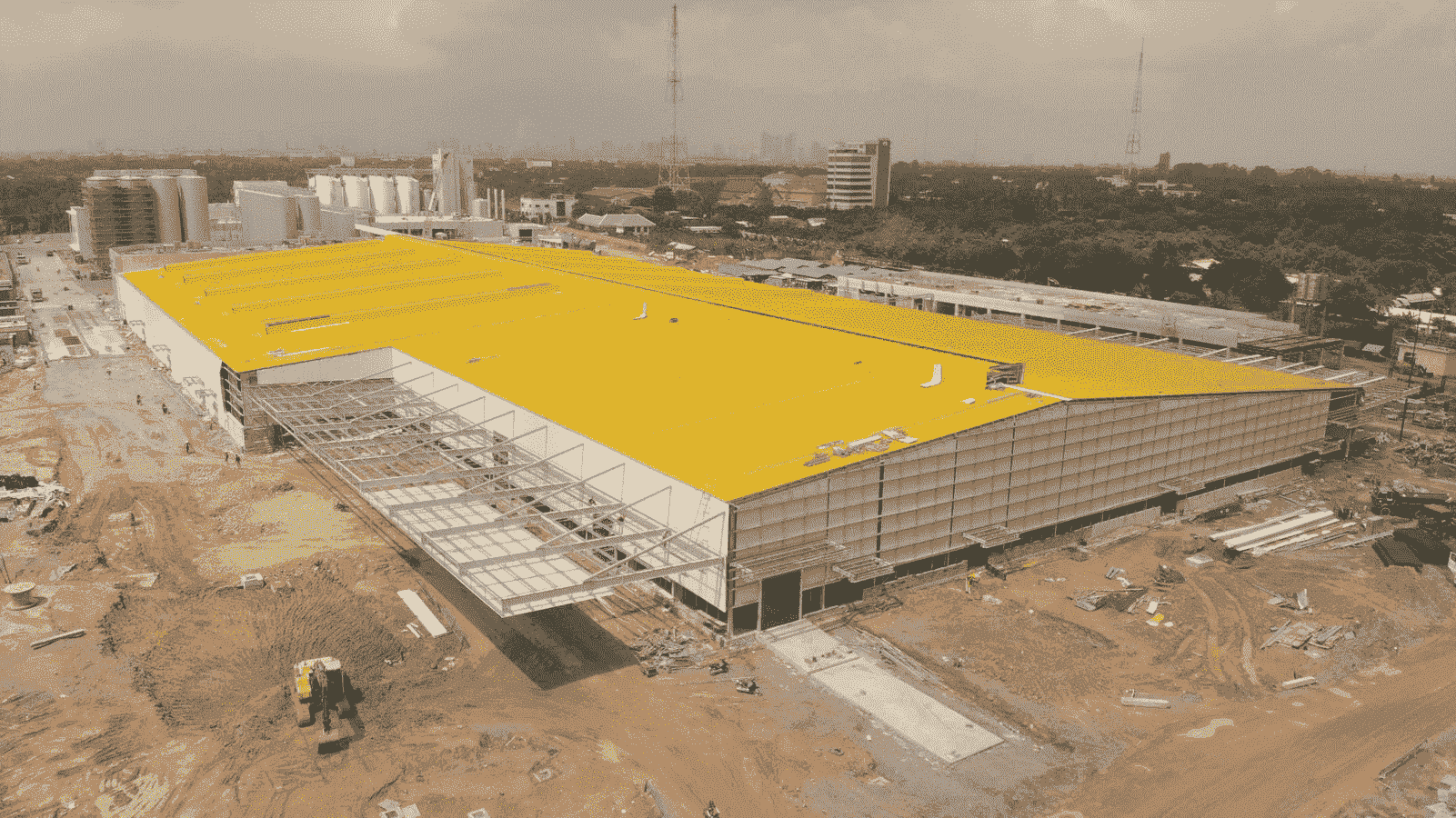

- Canopy roofs for industrial factory entrances.

- Skylight awnings for staircases in residential buildings.

- Garden canopy roofs.

- Greenhouse canopy roofs.

- Carport canopy roofs.

- Awning roofs for house patios.

4. Conclusion

Here is some information about the concept, classification, and applications of factory Canopy roofs. If customers seek comprehensive solutions for Pre-Engineered Buildings and Steel Structure, please contact Pebsteel via email at Marketing@pebsteel.com.vn or phone at +84 908 883531 for immediate consultation today.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.