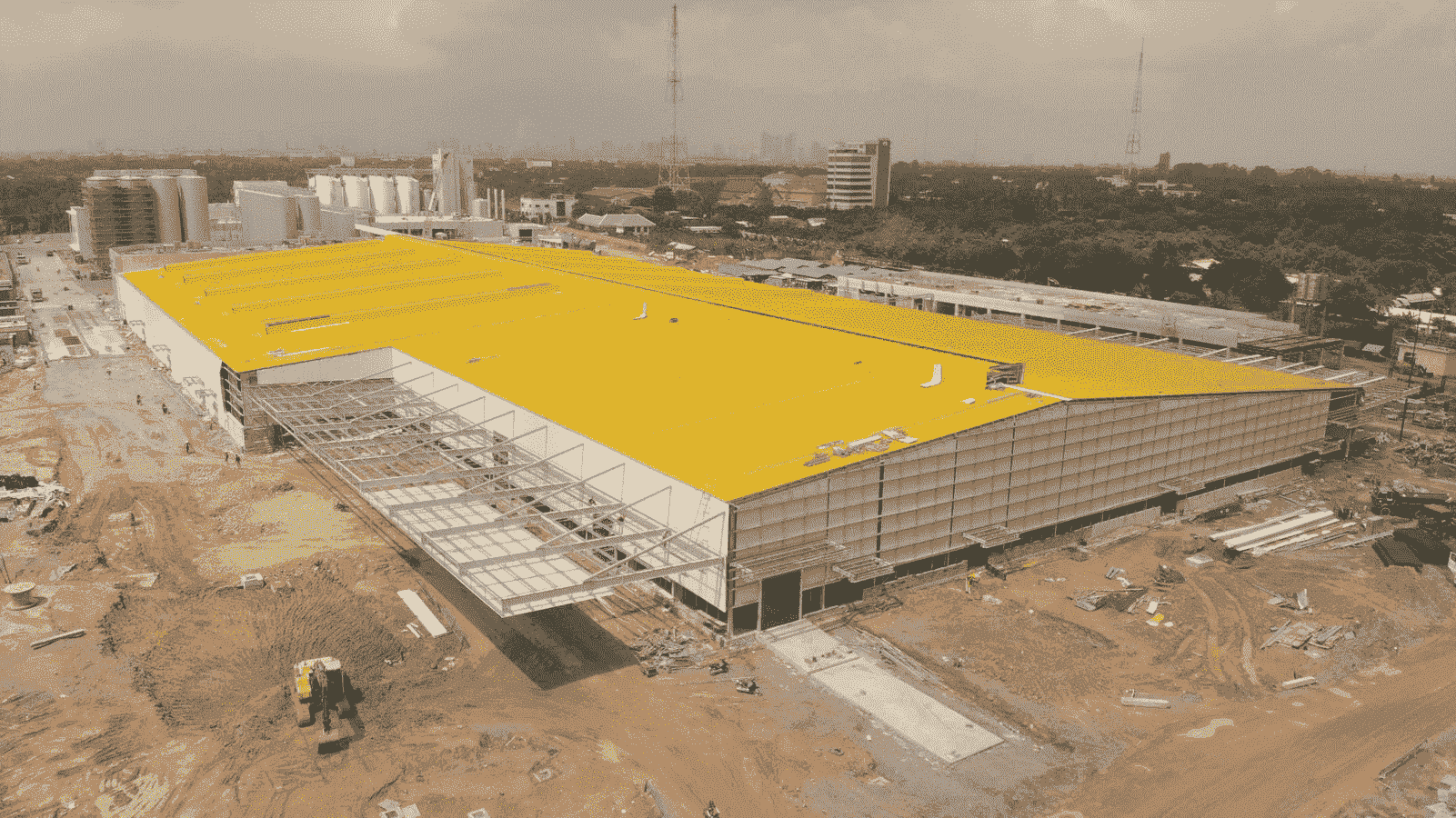

Costs of steel-structure factory construction are important information customers need to consider before making a decision of building investment. Join Pebsteel in exploring factors affecting construction costs and reference prices of some recently popular steel-structured factory designs.

What are pre-engineered steel factories?

Pre-engineered steel factories or prefabricated factories are types of buildings erected from steel members such as structures (trusses, columns, beams known as structural steel design), roofing panels, secondary compositions, steel construction connectors. All of the steel members are manufactured, fabricated in accurate quantities and dimensions in factories according to technical drawings, and transported to construction sites for a complete installation in a short period of time afterwards. Reference: Pebsteel pre-engineered steel building design and erection service.

Factors Affecting Costs Of Steel-Structure Factory Construction

In general, cost estimation is a necessary foundation to identify the construction costs of construction works, especially steel-structured factory constructions. Here are some factors affecting the costs of steel-structured factory constructions:

1. Factory size and composition requirements

The investors’ specific needs of building a factory determine the solutions, compositions and building materials of the factory. Foundation solutions, composition options, steel, heat-resistant materials, roofing solutions and attached auxiliary items are factors affecting the costs of steel-structured factory construction greatly.

2. Steel-structure factory designs

The costs of steel-structured factory constructions with modern design and special materials will be higher than that of simple and traditional design. Optimizing the pre-engineered steel structure options accompanied with foundation and material solutions will assist investors in reducing construction costs.

3. Building materials

Based on the specific needs of building a pre-engineered steel work, the construction unit will consider selecting suitable building materials. For instance, construction materials are highly required in building food-manufacturing, mechanical-processing or electronic equipment factories, resulting in higher construction costs compared to conventional factories.

4. Erection time

Steel is the main material used in factory construction (accounting for 70%), so the costs of the steel-structured factory construction specially depends on the price of steel. Nevertheless, steel prices may vary according to each period of time during the construction process.

The appropriate time for construction is at the beginning of the year as the weather is quite favorable, so normally building projects are just started, no need to be rushed. While many projects are catching up on the progress at the end of the year, rainy weather will have a bad influence on the erection time. At this time, if the erection time is lengthened resulting in many issues , the price of steel materials might change for the worse to the investors, as well as the increased labor costs. Therefore, during the cost estimation and construction cost considering stages, investors should also consider fluctuations in steel prices and erection time to avoid financial squandering.

Pebsteel process of steel-structure factory building service

Pebsteel pre-engineered steel building design and construction company is a reputable unit in the field of steel-structured factory construction and design with more than 27 years of experience, offering reassurance to customers when they experience the service. Pebsteel process of steel-structured factory construction service is implemented precisely at different stages.

Step 1: Idea development, solution suggestion

Initially, customers provide Pebsteel with the essential information of the project such as size of the factory, uses, and the desired construction progress. Based on the information, Pebsteel will provide different design solutions and analyze, evaluate and consult on selecting the most optimal solution for customers.

Step 2: Contract signing

As customers accept the construction quote, the two parties will begin to discuss more thoroughly about the construction process. Pebsteel and customers discuss and consent to the terms and construction process, then come to the stage of contract signing.

Step 3: Technical drawing establishment

Via the proposed solution accepted by customers, Pebsteel begins to finish the technical drawing for the project. This is a drawing directly related to the fabrication and installation as well as showing detailed technical structure of the entire project.

Step 4: Fabrication

During the fabrication process, Pebsteel strictly abides by the technical requirements of the drawings in an attempt to ensure the highest accuracy. The quality inspection stage at the factory is also tightly performed by Pebsteel to assure that there are no errors affecting the building quality and progress.

Step 5: Steel-structured building installation

The steel members will be transported to the construction site for the complete erection stage after the fabrication stage at Pebsteel’s factory. Supervising the erection quality at the construction site is a strict duty carried out by Pebsteel, in order to ensure no detected errors and accidents.

Step 6: Warranty

Pebsteel commits to 3 years warranty for materials, 10 years for compositions and always guarantees rapid and accurate handover of constructions according to the provided plan.

Today preferred, quality designs of steel-structure factory

Factors directly affecting costs of steel-structure factory construction for customer reference are presented above. For further information about prices and estimated costs of today quality factory designs, please contact Pebsteel via email Marketing@pebsteel.com.vn or hotline +84 908 883531 for direct consulting.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.