In the construction of works in general and structural steel constructions in particular, bearing structures play an extremely important role. It is the foundation that ensures quality, maintains durability, safety and longevity for projects. However, not every enterprise knows about this structure? In the article below, Pebsteel will share more useful information about bearing structures.

Bearing structures directly affect the quality of the constructions

Bearing steel frame structures are commonly used in constructions nowadays. Specifically, this type of bearing structure in which all types of vertical and horizontal loads pass through beams down to the column. The combination of bracing, beam and column details creates a solid support system. In which, the link between beams and columns is a hard link that enhances durability, firmly for the whole building.

Depending on the size and requirements of the project, the investor can consider different steel structure schemes. Here are the common types of bearing steel frame structures for customers to refer to.

1.1 Structure in the direction of bearing

Horizontal frame

- This is the bearing structure where the main beam position is located on the horizontal frame of the building. Its advantage is the large hardness, so the load capacity is good. Currently, the bearing horizontal frame is commonly applied in the construction of industrial works.

- Based on the materiality of the link between the column and the foundation, the link between the main beams and columns, the horizontal frame is classified into hard frames and matching frames.

- Hard frames are usually used for ordinary terrain, hard soil and uniform subsidence. This type of frame has good load bearing capacity and is commonly applied in building construction.

- The matching frame is used for the construction of works on soft ground, muddy soil, with non-uniform subsidence.

Vertical frame

Bearing vertical frame is a steel frame structure with the main beam which is located to length.

The advantage of the load-bearing vertical frame is the inexpensive material feature, easy to create balconies and splashes. This type of structure is also quite convenient to install the standing pipes across the floor and arrange rooms and spaces that are flexible.

1.2. Structure by Design

Double-roof truss

Includes a truss with the middle column and without the middle column.

- The middle columnless truss with a width of up to 180 meters is very suitable for hangars, logistics, and entertainment constructions.

- The truss with the middle column consists of more than one power-assisted column system according to the width of the building. With a maximum width that can be up to 200 meters, the middle column truss is usually suitable for low-roof sloping constructions in the logistics center, warehouse.

Single-roof truss

A single-roofed truss is a type of truss with a sloping roof only in one direction, extending from one wall to the opposite wall. Single-roof truss is a solution to save costs for constructions with a width that is less than 12 meters and is used for many types of constructions such as houses, warehouses, office buildings, shipyards …

Curved complex trusses

Curved complex trusses are often applied to architecture that emphasizes natural light, creating a sense of spaciousness and magnificence for public constructions such as airports, terminals, shopping centers, sports halls and entertainment centers. Curved complex trusses are also a popular choice in the construction of factories and logistics centers.

2. How is the steel structure formed?

Having durability and solidity, steel structures are commonly applied in heavy industrial projects, high-rise buildings, bridges, towers … Depending on the requirements and features of each project, steel components, construction designs will be crafted and built differently.

Usually, the bearing structure in the prefabricated steel building will be crafted from the following main components:

- Steel frame part: steel columns, steel floor beams and steel trusses.

- Bracing system structure: consists of bracing column and bracing roof. For prefabricated buildings, the bracing system is a very important component and directly affects the quality of the project.

- The Covering part: including wall purlins, corrugated steel walls and roof purlins.

- Sub-structures: such as decorative facades and frills, louvers, roofs, gutter systems,…

3. The project uses Pebsteel’s outstanding steel structure frame

Pebsteel is a prestigious pre-engineered building and steel structure construction organization, trusted by many investors to use services. After more than 27 years of operation, up to now, the organization has more than 6000 constructions in many countries such as Vietnam, Thailand, Laos … All projects ensure quality, durability and efficiency when put into use.

The typical of Pebsteel’s prefabricated steel building also consists of three main components:

- Steel truss composite with the shape of “I”

- Galvanized purlins with the shape of “C” and “Z” include wall purlins, gutter purlins, roof purlins.

- Corrugated steel roof, corrugated steel wall

In addition, the prefabricated steel building also has sub-structures and accessories to ensure full functions and meet the requirements of the investor:

- Sub-structure: mezzanine floor, power-assisted roof system or mezzanine floor (including beams and floors), crane beams (supporting the crane system), walkways,…

- Accessories and aesthetic details: roof, extended roof, decorative façade, decorative cladding frills, roof top ventilation, gutters, eavestrough, galvanized bracing cables …

Here are some prefabricated building projects that use Pebsteel’s typical bearing structure for your enterprise reference.

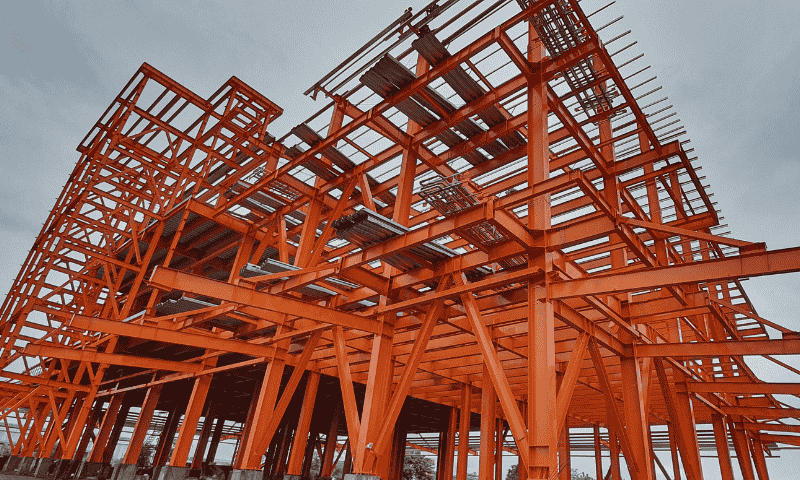

Pebsteel’s glove factory project in Thailand

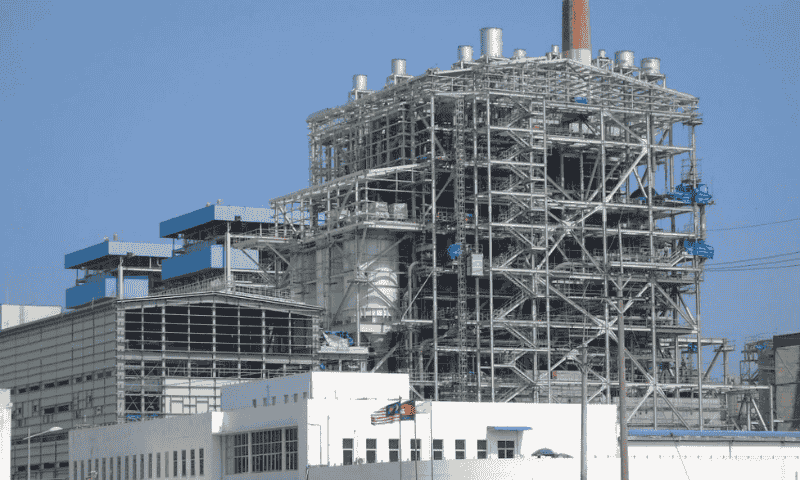

Fuel tank building project for Pebsteel’s thermal power factory

Pebsteel’s electronics factory project in the Philippines

Above is the information related to the bearing structure. If you still have questions that need to be answered and design for industrial building construction, please contact at the following email: marketing@pebsteel.com.vn or phone number +84908 883531 for specific advice.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.