The construction tendency of reinforced concrete warehouses is being replaced with the solution of using steel frames. So what are the advantages of designing and constructing pre-engineered steel industrial warehouses? How is the construction progress? Join Pebsteel to find out in details through this article below.

1. Pros of pre-engineered steel industrial warehouses?

Steel-frame industrial warehouse is the construction type with steel components which are processed at the factory, and then transmitted to the construction site to erect based on the detailed drawings. Currently, steel-frame buildings are widely applied for warehouses, factories, and office buildings,…The construction and design of industrial warehouses are being chosen by many enterprises due to these following advantages:

1.1 Outstanding specialities

Steel-structure industrial warehouses have good load-bearing ability and lighter weight compared to conventional concrete structures, so it helps the investors to save material costs for the foundation. Furthermore, pre-engineered steel buildings have the waterproof ability, which is better than other construction types by using concrete, bricks, wood; and it ensures that the using process won’t be affected.

1.2 Quick construction progress

All the steel components are processed at the factory and then transmitted to the construction site to erect, so the construction progress of industrial warehouses will quickly occur. Usually, the total construction progress will be about 3 or 6 months depending on the construction scale, which is considerably shortened in comparison with the construction method of using conventional concrete.

1.3 Cost-savings

The construction and design of steel-frame industrial warehouses optimize the budget for investors. The labor costs are greatly decreased due to the quick construction progress. Moreover, the steel-frame structure has lighter weight than reinforced concrete buildings, which decreases the loads for foundation. From that, the investors can save material costs for foundation treatment. In addition, most of the industrial warehouse design is following steel structure design. This is also considered an industry standard that any investor must follow.

2. Popular types of industrial warehouses

Nowadays, the design of industrial warehouses consists of 2 common types:

2.1 One-storey industrial warehouse

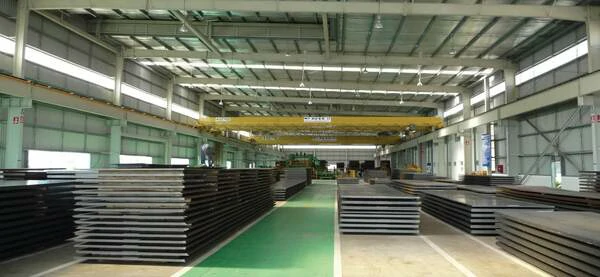

This is the most popular type of industrial warehouses nowadays. This type of warehouse has a small scale from 250 square meters to 500 square meters, medium scale from 500 square meters to 1000 square meters, and possibly larger than 1000 square meters, which is widely constructed in industrial zones having large areas. In addition, heavy industries which use overhead cranes, usually prioritize this model.

2.2 Multi-floor industrial warehouse

The model of multi-floor industrial warehouses is a new trend that is being preferred by many investors. This type of buildings will combine office with warehouse, which helps the investors to optimize the available area.

3. The construction and design process of steel-structure industrial warehouse

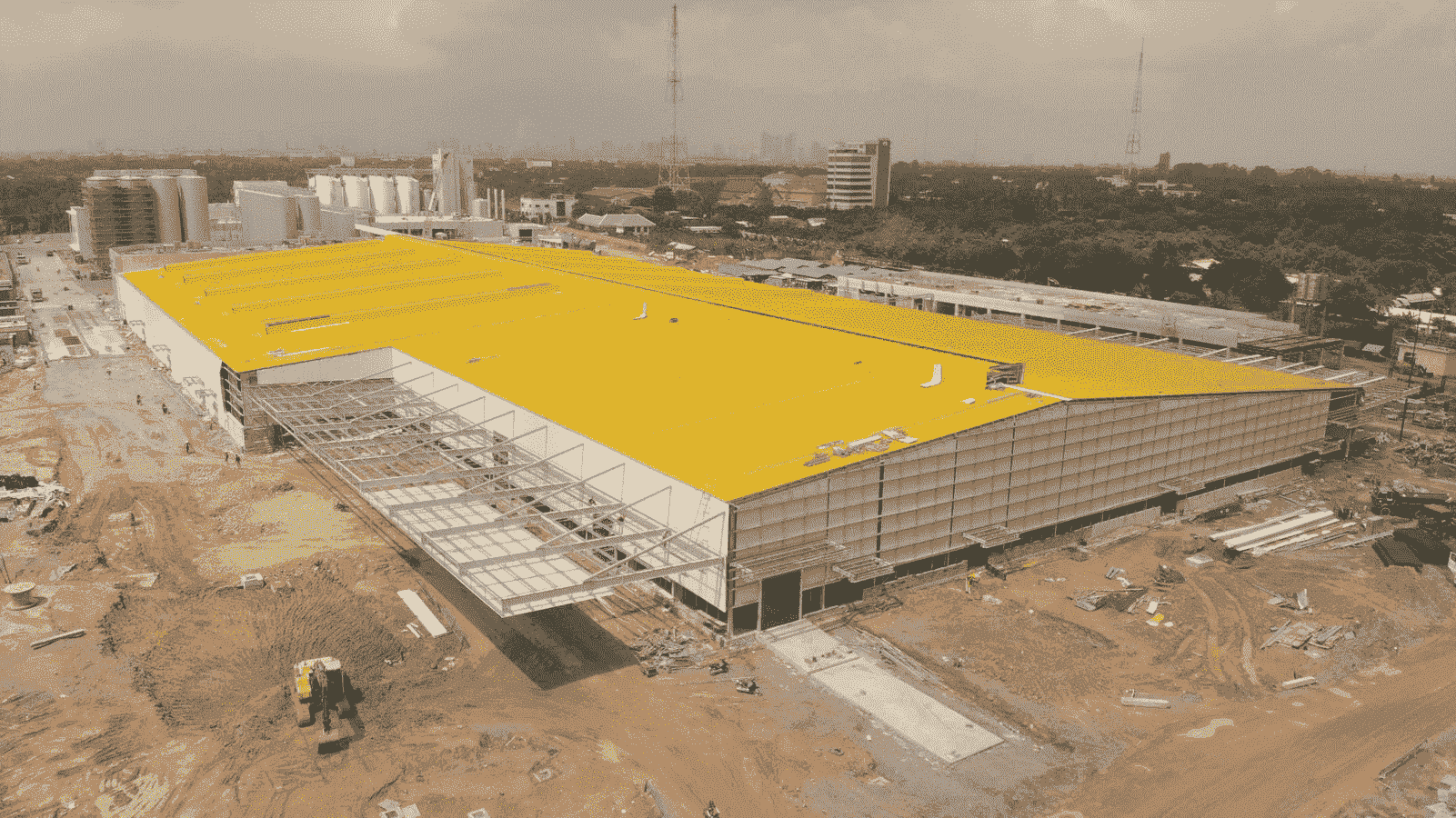

Pebsteel is the reputable construction-design organization for warehouses, civil buildings with pre-engineered steel components; having done more than 6000 constructions in Asia countries such as Vietnam, Philippines, Thailand. With great experience and professional technicians, Pebsteel is proud to satisfy the demands of customers.

Pebsteel’s process of designing and constructing industrial warehouses ensures to be transparent, high-quality, and optimizable for each customer’s demand. The details of construction progress are:

3.1 Making technical drawings

After signing the contract and understanding the detailed demands of customers, Pebsteel will quickly plan and make the technical drawings for every construction part of building the industrial warehouse. At the same time, the architecture team will calculate the main structure and building materials in a detailed manner.

3.2 Processing progress

The progress of processing the steel components will occur at the factory with modern devices, which is governed by strict rules to ensure the quality. This progres includes 7 parts which are: steel cutting, automatic welding, cleaning steel surfaces, metal spraying for steel surfaces, protective painting for steel surfaces and galvanizing, or pre-painted galvanizing for corrosion resistance. Usually, the time of this processing progress needs about 6 or 8 months depending on the construction scale, and quantity of materials that needs to be prepared.

3.3 Erection

After having finished the progress of processing the components, these parts will be transmitted to the construction site, and deployed to erect based on the technical drawings. The architecture and supervision team will strictly observe, check, and ensure that the construction is exactly-safely built.

3.4 Warranty

Pebsteel commits to warrant 10 years for the framing structure, and 3 years for materials after having finished the construction for the customers.

4. Design models industrial warehouses of Pebsteel

We hope that the above information will help the customers understand more about the progress of designing and constructing high-quality steel-structure industrial warehouses from Pebsteel. If the customers have any queries, you can contact Pebsteel at email Marketing@Pebsteel.com.vn or phone number +84 908 883531 for detailed consultations.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.