Pre-engineered Buildings (Prefabricated Steel Building or PEB, often used for factories, warehouses, hangars, etc.) allows for flexibility in design, so we can optimize the building’s utilities for aesthetics and end-user experience.

Product Features

- Optimum cost

- Premium products

- Speedy and efficient process

- Functional versatility & architectural flexibility

- Low maintenance and operating cost.

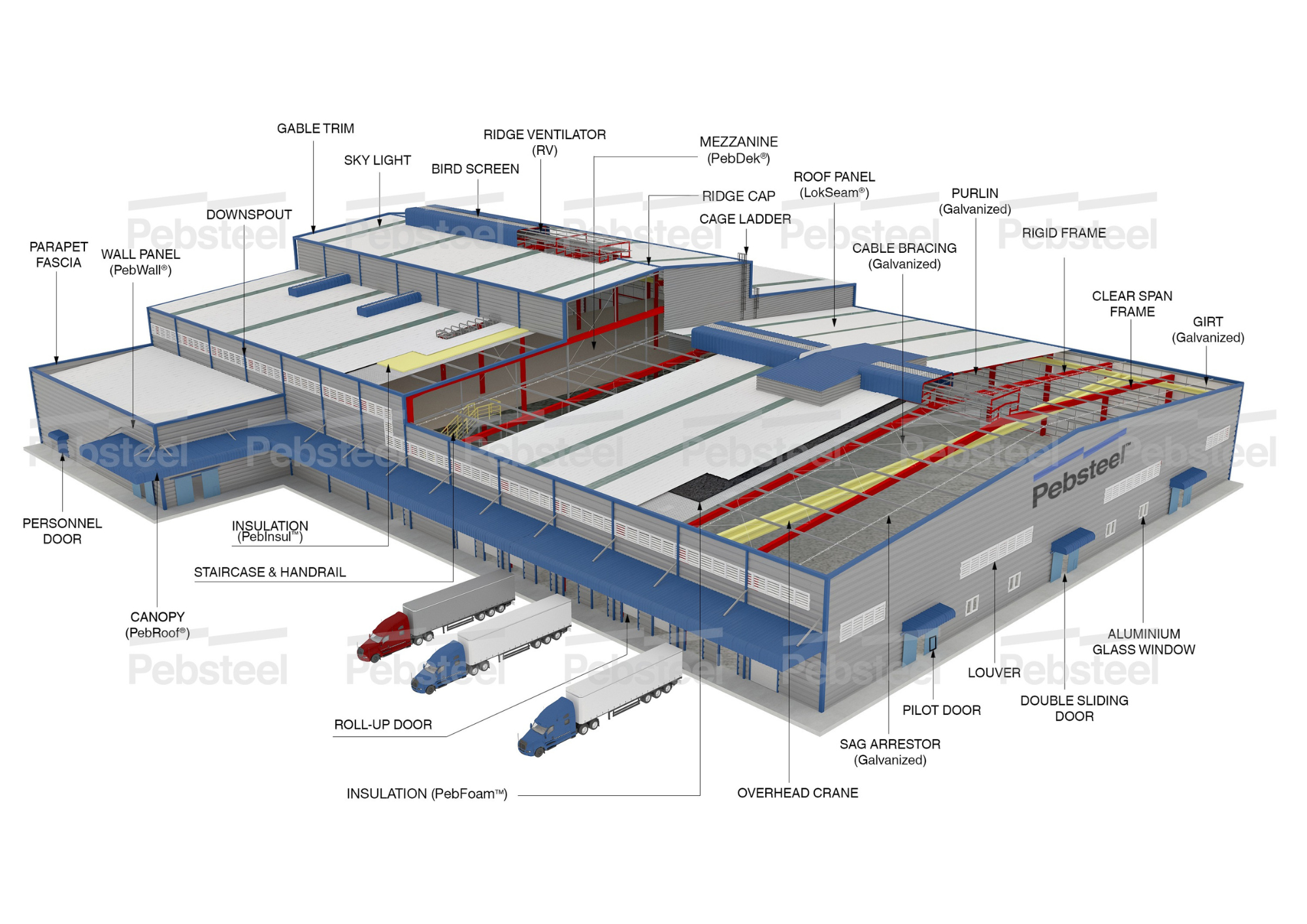

A pre-engineered building is a system utilizing three distinct product categories:

- Built-up “I” to shape primary structural framing members (columns and rafters)

- Cold-formed “Z” and “C” to shape secondary structural members (roof purlins, wall girts, and eave struts)

- Roll-formed sheeting profiles (roof and wall cladding).

Optional structural sub-systems and accessories are widely incorporated into pre-engineered buildings to ensure functionality as well as aesthetics:

- Functional sub-systems include mezzanine floors (including joists and decking), crane runway beams (to support crane systems), roof platforms, catwalks, etc.

- Aesthetic features and accessories include fascias, parapets, canopies, roof extensions, flashing and trims, eave gutter, downspout, galvanized bracing cables, ridge ventilation, etc.

Pre-engineered steel buildings are recently becoming popular since they perform better than conventional buildings in terms of cost-saving benefits and constructing speed.