Pre-manufactured steel buildings are gaining popularity in the industrial and commercial sectors due to their rapid construction, cost efficiency, and durability. They are an ideal solution for businesses looking to optimise budget and project timelines while maintaining rigorous quality standards. As a global leader in this domain and a recognised provider of steel structure fabrication in Vietnam, Pebsteel leverages cutting-edge engineering and manufacturing excellence to deliver structures that stand the test of time.

This comprehensive guide delves deep into the mechanics, benefits, applications, and selection criteria for prefabricated steel buildings, demonstrating why they are the definitive choice for modern enterprises.

1. What Are Pre Manufactured Steel Buildings?

Pre-manufactured steel buildings are complete, engineered systems consisting of pre-designed steel parts that undergo a streamlined process, including design, fabrication, transportation, and on-site installation. This method differs significantly from traditional construction, as most of the work is completed in a controlled manufacturing environment before being transported to the construction site.

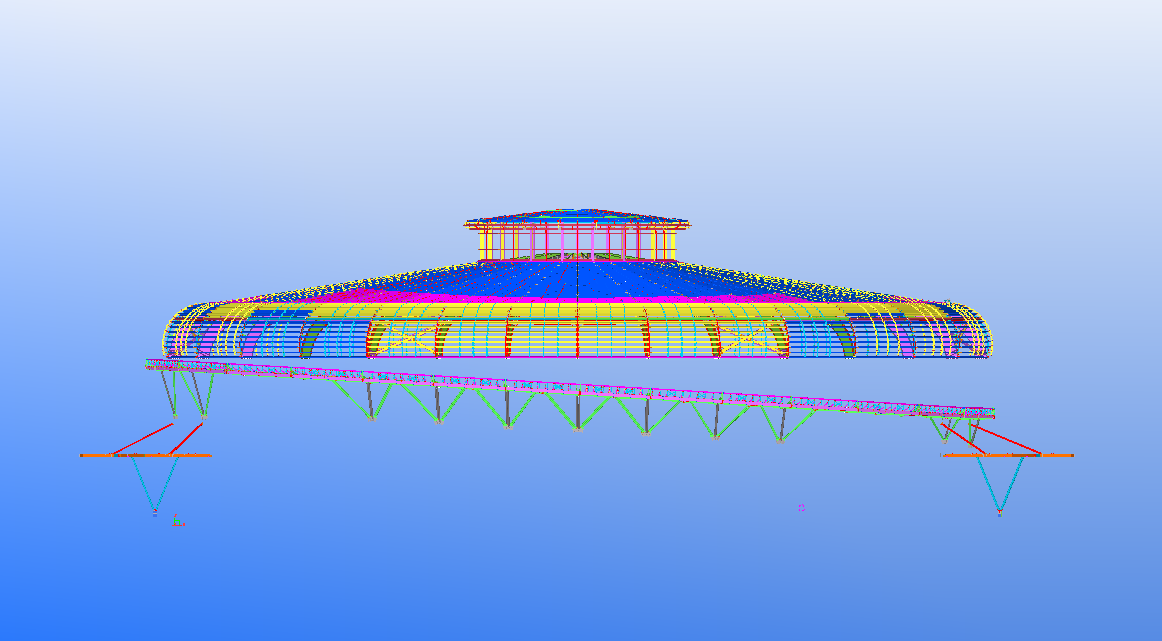

Pre-manufactured steel buildings are engineered off-site for faster, precise, and efficient assembly

2. The Engineering Behind the Structure

A typical steel building is comprised of several integrated systems:

- Primary Framing: This includes the rigid frames of the building, consisting of columns and rafters made from high-strength structural steel. These are the backbone of the structure.

- Secondary Framing: Cold-formed “Z” and “C” shaped purlins and girts typically support the wall and roof panels, transferring loads to the primary frame.

- Sheeting and Cladding: The external skin of the building, providing weather resistance and aesthetic appeal.

- Accessories: This includes turbo ventilators, skylights, sliding doors, and insulation systems that enhance functionality.

By fabricating these elements in a controlled factory environment, a structural steel fabricator like Pebsteel can ensure micrometre-level precision, eliminating the errors common in field fabrication.

3. The Comprehensive Benefits of Steel Structures

Why are investors globally shifting towards steel? The answer lies in the “Trifecta of Efficiency”: Time, Cost, and Quality.

Exceptional Speed of Construction

Time is often the most critical resource in capital projects. Pre-manufactured steel buildings significantly shorten construction timelines thanks to streamlined pre-fabrication and rapid on-site assembly. While the foundation is being poured on-site, the steel structure is already being manufactured in the factory.

- Parallel Processing: This overlapping schedule can reduce total project time by up to 50%.

- Plug-and-Play Assembly: Since connections are bolted rather than welded on-site, a small team can erect a massive structure in weeks rather than months, allowing businesses to start operations and generate revenue sooner.

Cost Efficiency and ROI

Customised, pre-manufactured steel buildings offer clear benefits in terms of financial planning.

- Material Optimisation: Advanced software designs the structure to use exactly the amount of steel required for the load, minimising waste.

- Lower Foundation Costs: Steel has a high strength-to-weight ratio, which reduces the need for extensive foundation work. Being lighter than concrete, it requires less massive foundations, resulting in significant savings on excavation and concrete costs.

Durability and Resilience

Clients can customise size, structure, and functionality according to their needs, but durability remains a constant standard. Structural steel is inherently resistant to termites, mould, and dry rot. With proper coating and galvanization—techniques mastered by Pebsteel—these buildings are impervious to rust and can withstand extreme weather events, including typhoons and earthquakes.

A pre engineered steel building constructed by Pebsteel meets the requirements of fast, cost-effective and flexible construction

4. Pebsteel’s Approach to Fully Customizable Steel Structures

One common misconception is that “pre-manufactured” implies “rigid” or “standardised” designs. On the contrary, flexibility is a core attribute.

Clients can customise size, structure, and functionality according to their needs. This solution saves construction time, reduces operational costs, ensures high durability, and allows easy future expansion.

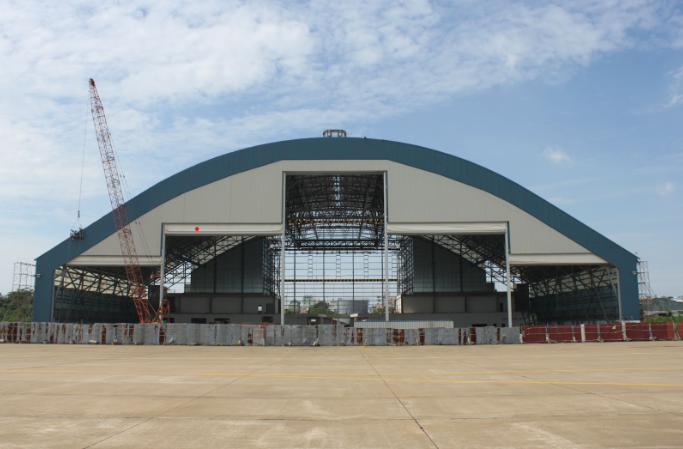

Whether you require a clear span of 100 meters for an aircraft hangar or a multi-story layout for an office complex, the design is adaptable to suit your needs.

- Flexible Modules: The building can be extended in length by simply adding more bays.

- Load Bearing: Designs can be adjusted to support heavy cranes, solar panels, or HVAC systems.

- Aesthetics: The days of boring grey boxes are over. Modern steel buildings incorporate glass curtains, fascia, canopies, and curved eaves to create striking architectural landmarks.

Discover More: Steel Structures Explained – Types, Benefits, and Applications

Custom-designed pre manufactured steel hangar with large clear-span steel structure

5. Applications in the Industrial Sector

The industrial backbone of the economy relies heavily on the reliability of its infrastructure. Pre-manufactured steel buildings are widely used for factories, production facilities, and logistics warehouses. They enhance production efficiency, optimise space, and provide flexible expansion options as businesses grow.

Manufacturing Plants

In manufacturing environments, the layout of machinery plays a crucial role in productivity. The clear-span design (column-free interiors) offered by pre-manufactured steel systems allows for completely unobstructed floor space. This open layout is essential for assembly lines, efficient material handling, and the smooth movement of forklifts or automated guided vehicles (AGVs).

Logistics and Warehousing

In the era of e-commerce, warehousing requires height and volume. Steel structures allow for significant eave heights, enabling vertical racking systems that maximise storage density per square meter.

Heavy Industry

For sectors like oil & gas or power generation, structures must support massive loads. Structural steel is the only material capable of handling overhead cranes with capacities exceeding 100 tons without requiring prohibitively expensive support columns.

Pre-fabricated steel buildings constructed by Pebsteel are being used by customers as the industrial production workshop

6. Transforming the Commercial Sector

Historically, steel was seen as purely industrial. However, innovation has brought it into the mainstream of commerce. In commercial projects, these buildings are suitable for shopping centres, showrooms, offices, and retail stores. Key advantages include aesthetic design, space optimisation, and cost-effective construction.

Showrooms and Retail

Car dealerships and furniture showrooms require large open spaces to display products. Steel frames facilitate wide glass frontages that traditional concrete columns would obstruct. This visibility is directly linked to sales performance.

Commercial Offices

Modern offices demand flexibility. A prefabricated steel building allows for internal partitions to be moved easily as teams grow or restructure, unlike load-bearing concrete walls, which are permanent.

7. Building Green with Recyclable and Energy-Efficient Steel

In an era where Corporate Social Responsibility (CSR) and Environmental, Social, and Governance (ESG) criteria are paramount, steel buildings offer a significant advantage.

- Recyclability: Steel is the most recycled material on the planet. At the end of a building’s lifecycle, 100% of the structural steel can be recycled without loss of properties.

- Energy Efficiency: Pebsteel utilises advanced insulation materials for roofs and walls, significantly reducing the energy required for heating and cooling. This contributes to obtaining Green Building certifications, such as LEED or LOTUS.

8. Why Experience and Technology Make Pebsteel the Trusted Fabricator

The construction market is crowded with service providers, yet the level of quality varies significantly. When selecting a steel fabricator, companies should evaluate the fabricator’s proven experience, completed projects, production technology, material standards, and the availability of design consultation and post-installation support.

Pebsteel operates as a comprehensive solution provider rather than a simple supplier. Its strengths are reflected in four core pillars:

- Experience: With decades of operational history and thousands of completed projects across Asia and Africa, Pebsteel brings deep insight into regional requirements, from challenging terrain conditions to strict climate and building codes.

- Technology: Advanced design software and automated fabrication systems ensure that every beam, column, and component is produced with uniform accuracy. This high level of precision enhances structural performance and long-term reliability.

- Materials and Standards: Pebsteel follows stringent global standards, including ASTM and equivalent international specifications for raw materials. This commitment ensures durability, structural integrity, and consistent performance throughout the building’s lifespan.

After-Sales Service: Steel buildings are long-term investments. Pebsteel supports clients with robust warranty policies, maintenance documentation, and responsive technical assistance, helping investors safeguard the value of their assets over time.

Pebsteel delivers reliable pre-manufactured steel buildings through expertise and advanced technology

9. Comparing Steel and Concrete Structures

To further illustrate the superiority of this solution, let us compare pre-manufactured steel buildings with Traditional Reinforced Concrete (RC).

| Feature | Pre-Manufactured Steel Building | Traditional Concrete Building |

| Construction Speed | Extremely Fast (Prefabricated) | Slow (Curing time required) |

| Cost | Low to Medium | High (Labour-intensive) |

| Foundation Load | Light | Heavy |

| Clear Span | Can exceed 100m without columns | Limited (Requires columns) |

| Seismic Resistance | High (Flexible material) | Low (Brittle material) |

| Sustainability | 100% Recyclable | Difficult to recycle |

| Expansion | Easy and clean | Complex and disruptive |

Customised pre-manufactured steel buildings provide clear benefits: speed, durability, cost savings, and flexibility. They are the optimal choice for businesses seeking to establish efficient infrastructure and achieve sustainable long-term growth.

10. Steel Structures Leading the Way in Next-Gen Construction

The construction industry is rapidly advancing toward higher levels of automation and digital integration. Modern steel building solutions increasingly rely on advanced design and visualisation technologies that enhance accuracy, detect potential design conflicts, and optimise material usage before production begins. These innovations also allow investors to preview structural concepts with greater clarity during the planning stage.

As land costs continue to rise, the ability to expand vertically through multi-story steel structures has become a critical advantage, especially for urban industrial parks where maximising space is essential.

Investing in infrastructure is one of the most significant decisions a business can make. Such an investment requires a trusted partner capable of delivering not only a functional facility but also long-term performance and operational reliability.

Pre-manufactured steel buildings represent the pinnacle of structural efficiency. They provide secure environments for manufacturing, efficient spaces for commercial activity, and durable foundations for economic growth. With rapid assembly, long-term cost effectiveness, and remarkable architectural flexibility, steel structures surpass traditional construction methods on nearly every performance metric.

Pebsteel is committed to bringing each project vision to life. With a strong focus on quality, safety, and forward-thinking innovation, Pebsteel ensures that every facility is not simply constructed — it is engineered for lasting success.

Ready to optimise your next project? Please contact Pebsteel immediately to receive a complimentary consultation from our team of highly experienced engineers:

- Email: marketing@pebsteel.com.vn

- Phone: (+84) 908 883 531

The information provided in this content is for general reference only and should not be considered as technical advice or a contractual commitment.