With the advantages of durability, fast construction speed, and optimal cost, corrugated steel roof workshops (steel sheds) are gradually becoming popular and attracting strong attention from many investors. Let’s join Pebsteel to learn more details about the concept of corrugated steel roof workshops and steel shed factories, as well as the process of designing and constructing high-quality corrugated steel roof buildings by Pebsteel through the following article.

1. What is Corrugated Steel Roof Factory

The popular corrugated steel roof factory is now the type of construction that owns a steel bearing frame on the concrete foundation. Besides the usual corrugated steel roof, the wall of this building is also covered with corrugated steel. As a result, the construction time of the corrugated steel roof factory is significantly shortened compared to the traditional way of building from bricks, reinforced concrete and wood. Corrugated steel roof factory is the first choice of many domestic and foreign corporate customers.

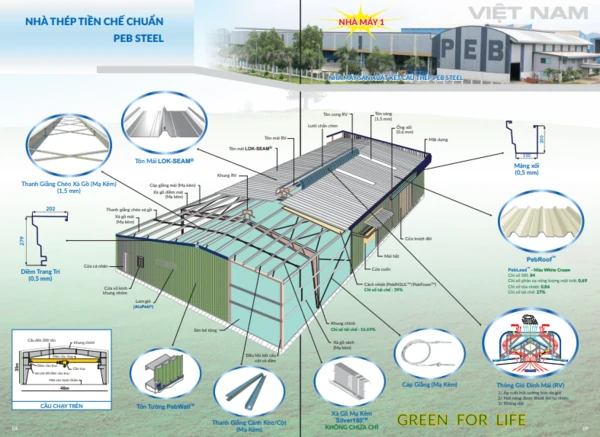

2. The main structure of the pre-fabricated steel frame corrugated steel roof factory

2.1 Main Steel Frame Structure

The main steel frame structure of the corrugated steel roof factory usually includes:

- Steel frame system: Consists of parts such as columns, trusses, beams. In particular, for factories with structures made from steel, it is common to use H-shaped columns or some other types of columns such as circular columns for some special works. Beams are often used in common types with an I shape.

- Bracing system: Includes purlin bracing, roof bracing, gable head bracing, column bracing,… Bracing components can take the form of bracing rods or bracing cables, which have the function of enhancing the solidity and bearing capacity of the main frame system.

- Purlins: with two common types of C or Z shape, purlins are indispensable components in every corrugated steel roof workshop. Not only is the padding necessary for roofing and walling, purlins also effectively link the spans and help the entire frame system firmer.

2.2 Corrugated Steel Roof System

Depending on the specific design and requirements during use (e.g., aesthetic requirements, fire resistance requirements) that corrugated steel roof factory walls can be entirely corrugated steel or a combination of corrugated steel and brick/concrete. For roofing, investors need to note the following 3 factors:

- Corrugated steel roof materials: there are now many types of roofing steel made from plastic, zinc, galvanized steel, cement fibers / fibro roofing panels, fiberglass,… Each material determines the durability, safety, construction characteristics, as well as the auxiliary effect for the work such as natural light retrieval, heat reflection, corrosion resistance.

- Corrugated steel roof design: besides the usual screw-firing roofing, there are also folding corrugated steel, round wave corrugated steel, square wave corrugated steel, decorative steel, anti-leaking corrugated steel,…

- Corrugated steel roof color: not only ensuring aesthetic requirements, roofing color and roofing coating structure also contribute significantly to ensuring durability, reducing power consumption, heat reflection and increasing color durability.

In order to choose the type of corrugated steel roof suitable to the characteristics of the building and architectural requirements, the investor and contractor need to consider the environmental factors, climate around the building as well as the environmental characteristics inside the building. For example, a building near the sea or livestock works is often subjected to serious corrosion agents such as air high in salt and moisture, pet waste, so the investor needs to use an anti-corrosion corrugated steel roof.

2.3 Substructure system and accessories:

The system of auxiliary structures and accessories of the corrugated steel roof factory includes: windows, back doors, gutters, roof top ventilation,… aimed at perfecting the use, increasing aesthetics and extending the life of the works.

3. Quality corrugated steel roof of Pebsteel steel buildings

For types of steel buildings, Pebsteel uses the following types of quality corrugated steel roof:

Corrugated steel types:

- LokSeam: is a folding corrugated steel roof that is resistant to extreme weather, anti-leakage and prevents damage caused by heat stretching. The product has a special design that removes 80% of fixed screws compared to conventional types of corrugated steel.

- PebDek: is a floor corrugated steel developed by Pebsteel with cold-rolled steel and is combined with concrete, floor steel frame to create conjugated flooring in pre-fabricated steel buildings.

- PebLiner: is a type of corrugated steel used as a corrugated steel roof for the walls and roofs inside the pre-fabricated building.

- PebSeam128: Is a type of corrugated steel roof with a vertical edge folding design developed by Pebsteel from LokSeam corrugated steel and applied in buildings with a significantly wide roof system.

- PebWall: Is a type of screw-firing roof with a 900mm wide version and is used for wall steel systems. PebWall corrugated steel is suitable for most commercial, industrial or architectural works thanks to its sturdy corrugated steel waves and beautiful design.

4. Construction process of Pebsteel corrugated steel roof factory

4.1 Building technical drawings

With a team of 1500 employees including more than 100 experienced engineers, Pebsteel always thoroughly understands the needs of customers and develops technical drawings through many professional construction materials design and management software such as SAP, Tekla, Strumis,… to propose the most optimal solution.

4.2 The machining process consists of 4 stages

After signing the technical drawing, Pebsteel will process the steel component at the factory through 4 stages:

- Cutting steel with heavy machinery such as CNC, Plasma

- Welding steel complexes to shape components

- Surface cleaning of steel components with metal ball sprayer

- Corrosion-resistant paint to protect steel surface

4.3 Installation

After the steel components are processed and tested for quality at the factory, these components will be packed and transferred to the construction site for construction. This shortens the time compared to traditional types of construction such as reinforced concrete.

4.4 Maintenance

Pebsteel is committed to a 10-year structural maintenance, and a 3-year material maintenance. Pebsteel’s maintenance policies always aim to optimize the efficiency of use and extend the life of the entire building for customers. Above is Pebsteel’s information about the concept and process of construction of corrugated steel roof factory today. Hopefully, the above useful information helps customers to choose for themselves the model of corrugated iron roof factory suitable for their needs. For any questions to be answered about steel structure or structural steel design, please contact at the following email: marketing@pebsteel.com.vn or phone number +84 908 883531 for free consultation.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.