Corrugated steel roof is an indispensable component in housing works, warehouses, factories,… steel frame. Currently, there are many types of corrugated steel roof with an abundance of features, styles and colors to meet the diverse needs of customers. Join Pebsteel to refer to some of the most popular types of roof steel on the market in 2025 through the article below.

Popular types of corrugated steel on the current market 2025

Corrugated steel roof is a material that is commonly used in construction works such as houses, factories, warehouses… to protect the building from the impact from the external environment such as rain and sun, storm wind. In addition, corrugated steel roofs have many designs, materials, colors with a variety of prices, meeting many different requirements of the building. Currently, the common types of corrugated steel on the market can be mentioned as:

Cold corrugated steel

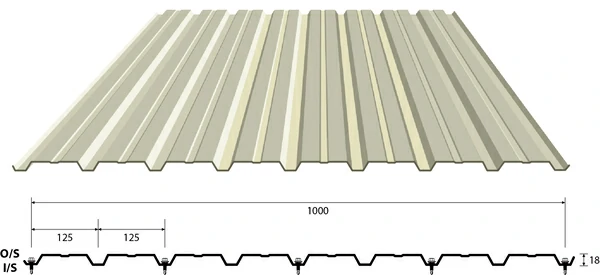

Cold corrugated steel is produced with cold rolled steel and plated with zinc aluminum alloy. Cold corrugated steel is also known as zinc-plated corrugated steel, or color-plated corrugated steel if coated with colored paint.

Cold corrugated steel, especially color-plated corrugated steel has a higher anti-corrosion and aesthetic effect than other types of corrugated steel.

Corrugated Steel

Corrugated steel is a type of corrugated steel designed to increase aesthetics as well as meet the requirements of construction works. Common waves include square waves and round waves. In addition to aesthetically enhanced properties, corrugated steel also has the function of ensuring the durability of the roof, reducing noise when there is heavy rain, increasing the hardness and resilience of the roof to weather impacts (rain, storm, whirlwind,…).

Depending on the aesthetic requirements and characteristics of the building, it is necessary to choose the right type of corrugated steel to ensure functionality and limit waste of materials. With steel frame industrial buildings as well as civil construction today, square wave corrugated steel is more commonly used than round wave corrugated steel.

Tile imitation corrugated steel

Tile imitation corrugated steel is a type of corrugated steel roof that is designed based on the shape of the tile roof used in construction. With high aesthetics, tile prosthetics are often chosen for use in housing and cultural works.

Galvanized Corrugated Steel

Galvanized corrugated steel is a type of corrugated steel that is supplemented with aluminum – zinc alloy plating to increase corrosion resistance. The galvanized layer also helps to increase the durability of the product.

Cool corrugated steel

Cool corrugated steel is also known by many other names such as sandwich panel, PU corrugated steel, insulation,… thanks to the characteristic structure of 2 corrugated steel covering layers of fireproof material, insulation in the middle. Cool corrugated steel is widely applied in industrial, commercial and civil constructions.

See more: What is a Steel structure? Main type of steel structure building

Type of corrugated steel roof used in prefabricated steel frame building

For steel frame buildings, galvanized corrugated steel with rolling wave is the most optimal choice.

Features required of corrugated steel roof of prefabricated steel building

Corrugated steel roof used in prefabricated steel buildings has the following features:

Effective heat resistance

Heat resistance is one of the outstanding advantages of corrugated steel roofs in prefabricated steel buildings. Due to its distinct features as well as the demand for use, steel buildings prioritize the use of materials with high heat resistance. The use of Galvanized Corrugated Steel will help against the effects of the sun, keeping the indoor space airy.

High corrosion resistance

With the addition of galvanized layers on the surface, the corrugated steel has the ability to restrict the impact of external agents in the environment to help galvanized steel roofs possess the advantages of being difficult to corrode.

High durability

One of the reasons that galvanized corrugated steel which has wave rolling is the perfect choice for prefabricated steel buildings is high durability. With the structure from thin rolled steel plates and covered with zinc after hot dip will help the galvanized corrugated steel with high durability.

Variety of designs

Currently, galvanized corrugated steel roof has been designed and manufactured with diverse designs and colors with the ability to meet all aesthetic requirements of the investor.

Easy to install and cost saving

The installation of a galvanized corrugated steel roof is simple and fast because the light weight will save construction costs.

See more: Structural Steel: Types, Properties, And Applications

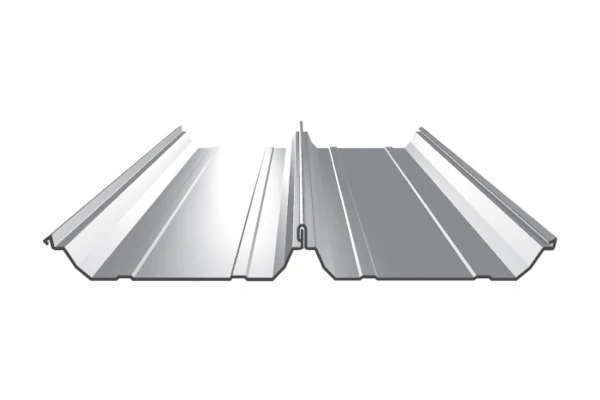

LokSEAM® Corrugated Steel Roof – The optimal choice for prefabricated steel buildings

LokSEAM Corrugated Steel Roof is one of the corrugated steel products which achieved FM Approved certification for quality, optimal choice for prefabricated steel buildings.

With a special design, LokSEAM® corrugated steel roof allows to remove up to 80% of the fixed screws compared to other commonly used corrugated steels. Standard length of LokSEAM® roofing 120m without joints will help save time and construction costs significantly. In terms of parameters, the LokSEAM corrugated steel roof has a corrugated steel wave height of about 66mm, the minimum slope of the roof is 3% and the distance between the corrugated steel waves is about 470mm. The product not only has extremely good heat resistance, corrosion resistance, but also helps to minimize water leakage or heat elasticity. That’s why LokSEAM® corrugated steel is a quality choice to use in prefabricated steel buildings.

Currently, LokSEAM® and PebSEAM® corrugated steel roofs are types of corrugated steel roof developed by Pebsteel from LokSEAM® steel with a length of up to 150m are applied in most prefabricated steel buildings constructed by Pebsteel. Choosing the right corrugated steel roof products has a very important part for the construction of prefabricated buildings.

Pebsteel hopes to have provided useful information to customers. If you have any questions that need to be answered, please contact Pebsteel by email marketing@pebsteel.com.vn or call hotline +84 908 883531 for specific advice.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.