The food industry demands optimal construction solutions to cater to the needs of safe, efficient food production, storage, and distribution. Prefab steel buildings have emerged as a frontrunner in this industry, offering a compelling combination of structural excellence, flexibility, high load-bearing capacity, and cost-effectiveness. This article delves into the diverse applications of prefab steel buildings in the food industry, empowering businesses with an optimal solution to enhance operational efficiency and boost profitability.

1. Practical Benefits of Prefab Steel Buildings in the Food Industry

Prefab steel buildings offer a multitude of practical advantages for the construction and manufacturing industry, particularly within the food sector. Here are some notable highlights:

- Food Safety and Hygiene: Prefab and pre-manufactured steel buildings feature tightly sealed structures that minimize the intrusion of insects and microorganisms, ensuring a clean production environment. Smooth steel surfaces enable easy cleaning and disinfection, fully complying with strict food safety regulations.

- Cost and Construction Time Optimization: Prefab steel buildings boast lower construction costs compared to traditional buildings due to the prefab component manufacturing process and reduced material wastage.

- Enhanced Production Efficiency: The spacious and airy nature of prefab steel buildings promotes efficient air circulation and temperature control, optimizing production processes. This controlled environment minimizes product spoilage and maintains consistent quality standards.

- Energy Efficiency: The structural design of prefab steel buildings allows natural light to illuminate the interior, significantly reducing the need for artificial lighting. This translates into substantial energy savings and a commitment to environmental sustainability.

- Effortless Expandability: The flexible structure of prefab steel buildings enables seamless expansion of floor area when necessary. This adaptability caters to growing business needs and facilitates future expansion plans without compromising structural integrity.

- Exceptional Longevity: Prefab steel buildings boast a remarkable lifespan of up to 50 years or more, offering a long-term return on investment. The durable steel structure withstands harsh weather conditions and heavy loads, minimizing maintenance costs and ensuring enduring performance.

- Modern Aesthetics: Prefab steel buildings come in a wide array of designs and colors, catering to diverse architectural preferences. This aesthetic versatility enhances a company’s brand image and contributes to a visually appealing industrial space.

The benefits of prefab steel buildings make them a rational and effective construction solution, especially in the context of the food industry which is increasingly demanding higher standards of safety and production efficiency.

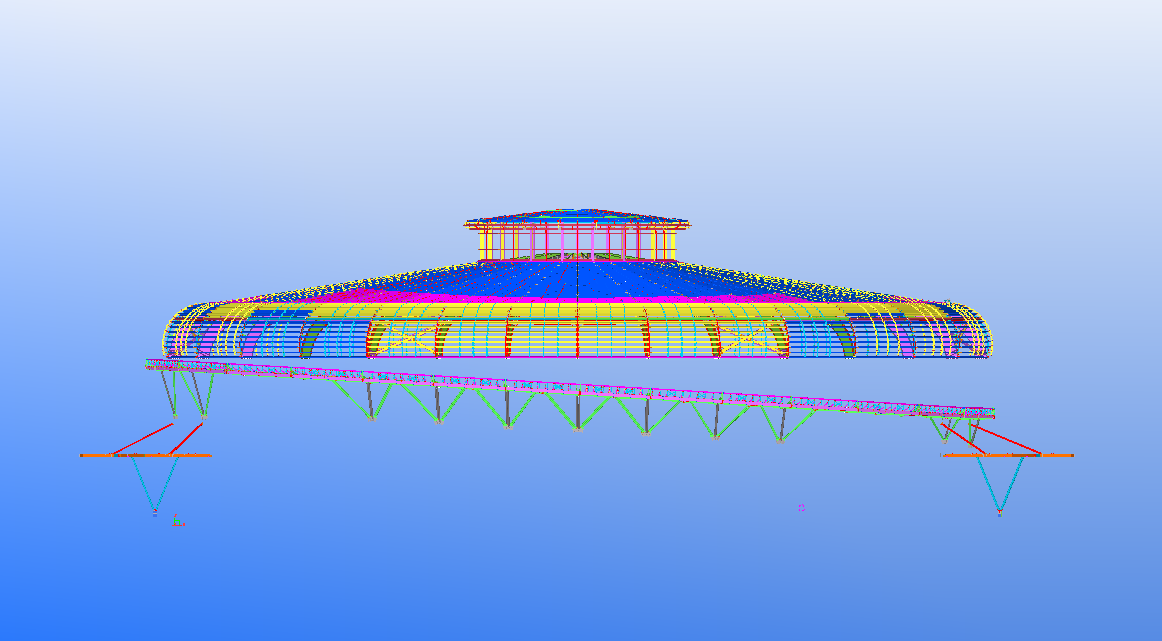

Practical benefits of pre-engineered steel buildings in the food manufacturing industry

2. Diverse Applications of Pre-engineered Steel Buildings in the Food Industry

2.1. Food preservation facility

Pre-engineered steel buildings are the perfect solution for food preservation, featuring suitable application designs such as:

- Refrigerated storage: Well-insulated roof and partition systems on prefab steel structures provide efficient temperature and humidity management, providing the perfect setting for the preservation of fresh and frozen goods including meat, fish, and vegetables.

- Raw material storage: The spacious, airy space of prefab steel buildings helps preserve food processing ingredients in the best conditions, avoiding mold and damage.

- Production area: For the manufacturing area, machinery installation, and food processing lines, safety is guaranteed by the prefab steel building’s robust, load-bearing steel frame structure.

2.2. The packaging section

Packaging centers or units within food manufacturing facilities have specific space requirements for:

- Product packaging area: requires roomy, open area to support the best possible packing practices and guarantee food safety and cleanliness.

- Packaged product storage: to keep products in optimal condition and shield them from the elements, a roof and partition system are required.

Therefore, the application of steel structures in prefab steel buildings, particularly the truss frame design without center columns, will facilitate the easy storage and transportation of commodities. The strength and durability of steel also contribute to ensuring the safety of packaged food products.

2.3. Distribution center

Modern distribution centers also require ample space to support logistics operations and facilitate the convenient loading and unloading of goods, such as:

- Warehouse: Generous space, simple to organize and categorize items, ideal for efficiently storing and delivering food items.

- The import-export region: large entrance gate that makes it easy to move cargo in trucks and containers.

The use of steel structures helps optimize space, storage, and makes the transportation of goods more flexible. The robustness and load-bearing capacity of steel also help ensure the safety of packaged goods, particularly for food products.

Application of pre-engineered steel buildings in the food industry

2.4. Food packaging production area

A food packaging production facility requires ample and well-designed open spaces to improve operational efficiency, including the following key areas:

- Packaging manufacturing zone: Food safety and cleanliness are ensured by the efficient use of large, airy spaces during the packing process.

- The finished packaging storage warehouse: The roof and partition wall system helps to store the finished packaging materials in the best conditions, shielding them from external environmental impacts.

2.5. Seafood processing area

Food processing areas need to be designed to be spacious and closed, to help ensure hygiene and maintain product quality. These areas include:

- Seafood processing factory: Closed environment, easy to clean helps ensure food hygiene and safety for seafood products.

- Frozen warehouse: An effective insulation system helps preserve frozen seafood products for a long time.

Prefabricated steel buildings meet excellent food hygiene and safety requirements, providing a clean and easy-to-manage environment, making them the ideal choice for seafood processing areas.

2.6. Functional food production area

The functional food production area will include 2 main areas:

- Functional food factories: require durable structures and easy cleaning to help ensure food hygiene and safety for functional food products. Aspects of steel structure are clearly shown in steel structure design.

- Laboratory: requires a closed environment, easy to clean, creating favorable conditions for research and testing the quality of functional food products.

Prefabricated steel buildings, with many outstanding advantages, are the perfect choice for building functional food production areas.

2.7. Retail stores and restaurants

Prefab steel buildings with outstanding structural advantages, flexibility and aesthetics have emerged as the perfect solution for modern food retail stores and restaurants.

- Flexible customization: Flexible steel frames allow architects to easily design and construct details according to creative ideas, creating a unique highlight for the store or restaurant.

- Large windows bring in natural light: The spacious windows maximize the use of natural lighting, creating a bright and airy ambiance, saving on energy costs, and providing customers with a comfortable, welcoming atmosphere for shopping and dining.

- Intelligent mezzanine: Mezzanine design helps double the usable area, meeting the needs of displaying products, arranging a dining area or creating a separate space for other activities.

- Spacious storage: The flexible floor plan of the pre-engineered steel structure allows for the arrangement of spacious storage areas, ensuring the safe and hygienic storage of raw materials and food products.

- Modern kitchen area: The strong steel construction enables the integration of a sophisticated kitchen system with advanced cooking and baking equipment to support the preparation of a diverse range of delectable dishes.

In addition to the above applications, pre-engineered buildings are also used to build office areas, cafeterias, restrooms, etc. to serve the production and business activities of food processing enterprises.

Retail stores and supermarkets made of prefab steel buildings

3. Key Considerations for Designing and Constructing Prefab Steel Buildings in the Food Industry

Designing and constructing prefab steel buildings for the food industry requires meticulous attention to detail and strict adherence to food safety standards. Here are some specific key considerations to focus on:

3.1. Material selection

The steel surface needs to be treated with anti-rust, galvanized or painted with a suitable protective layer to avoid corrosion in humid and chemical environments. Materials for roofs, partitions, and doors must ensure good waterproofing, fire and explosion resistance.

3.2. Structural design

The steel structure must ensure good bearing capacity, anti-vibration, anti-sinking, suitable for the load of the system of machinery, equipment, and products stored inside.

The distance of columns, beams, and trusses needs to be calculated properly to optimize the usable area and create favorable conditions for forklifts and trucks to move. The roof must have a suitable slope to drain rainwater quickly, avoiding stagnation of water causing dampness and mold.

3.3. Ventilation and air conditioning system

The ventilation system must be designed effectively to ensure air circulation in the factory, eliminate odors, harmful gases and maintain a cool working environment.

The air conditioning system (if necessary) needs to be arranged appropriately to control the temperature and humidity in the factory in accordance with food preservation requirements. It is necessary to install an exhaust fan system in the kitchen area and food processing area to remove odors and grease.

3.4. Waterproofing and fire protection system

Roofs, partitions, and doors must be constructed with good waterproof materials to prevent rainwater from penetrating and protect food and equipment from damage.

The electrical system must be installed safely, using electrical wires, sockets, and waterproof and explosion-proof electrical panels. It is necessary to equip a fire alarm and automatic fire extinguishing system to ensure safety for people and property in case of an incident.

3.5. Sanitary system

The floor surface must be made of smooth, glossy material that is easy to clean and disinfect. The floor drainage system must be designed effectively to drain wastewater quickly, avoiding water stagnation and pollution.

It is necessary to arrange a system of handwashing faucets and adequate personal hygiene areas in convenient locations for workers.

3.6. Light

Natural lighting systems should be used in combination with artificial lighting systems to ensure enough light for food production and processing activities.

Lighting must be arranged properly to avoid causing glare and affecting workers’ vision. You should use energy-saving light bulbs to reduce electricity costs.

3.7. Ability of extension

Prefab steel building structures need to be designed flexibly so that the area can be easily expanded in the future when production needs increase. The expansion needs to ensure compliance with structural, safety and food hygiene standards.

Specific considerations for designing and constructing prefab steel buildings in the food industry

In general, pre-engineered steel buildings bring numerous practical benefits to the food industry, enabling businesses to optimize costs, enhance operational efficiency, ensure food safety, and establish a professional brand image. Choosing pre-engineered steel buildings for applications in the food industry is a wise decision that contributes to sustainable business development.

For comprehensive solutions in prefab steel building construction, feel free to contact Pebsteel via email at marketing@pebsteel.com.vn or phone at (+84) 908 883 531 for immediate assistance!

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.